Preparation method of stannous methanesulfonate

A technology of stannous methanesulfonate and aqueous solution, which is applied in the direction of electrolysis, organic chemistry, electrolysis components, etc., can solve the problems of long reaction time, high reaction temperature, and many by-products, and achieve fast reaction speed and simple post-processing , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

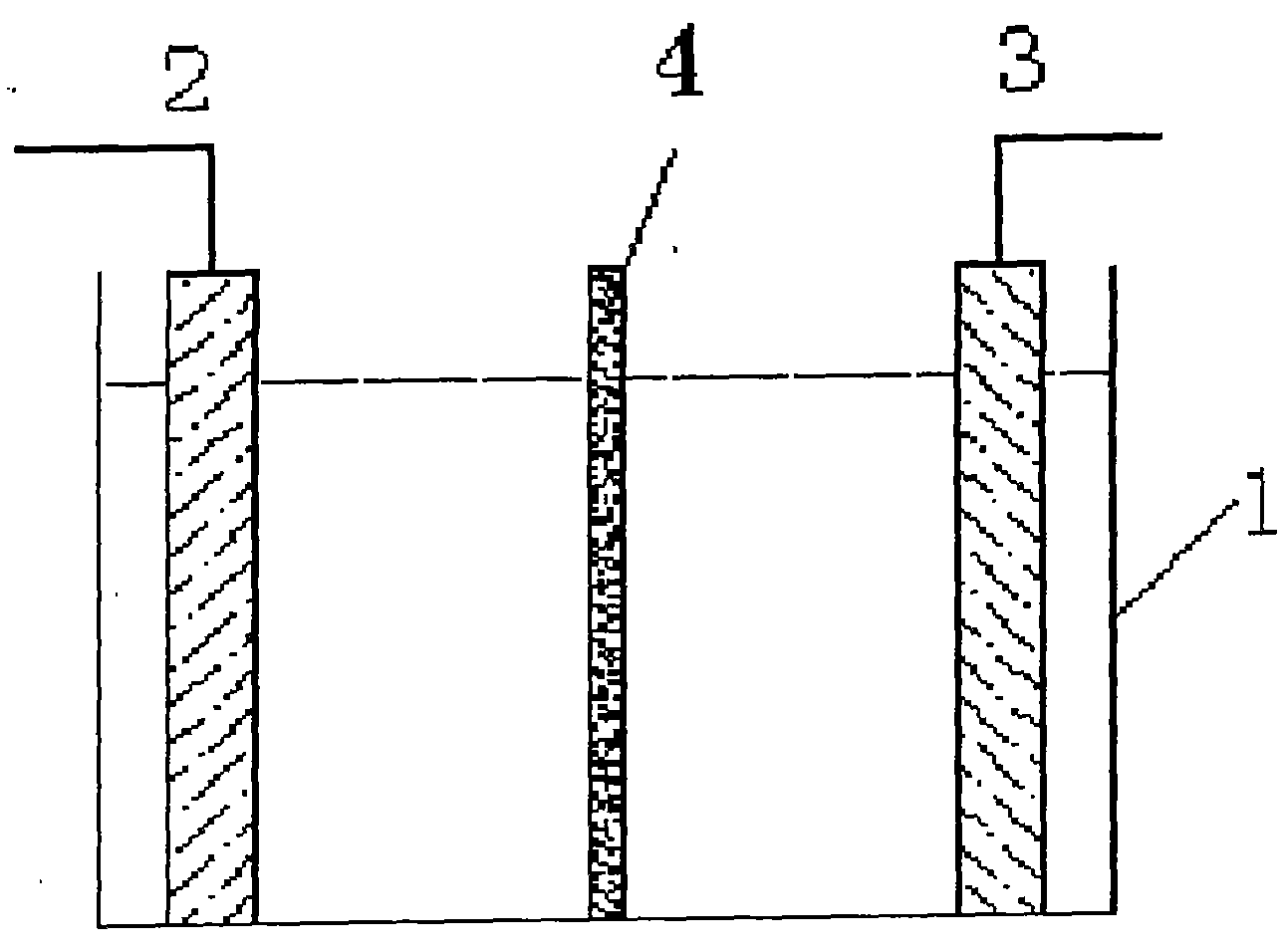

[0016] Embodiment 1: referring to accompanying drawing, electrolytic method prepares stannous methanesulfonate method, in diaphragm type polypropylene outer frame electrolyzer 1, oppositely set has the high-purity tin plate anode 2 and negative electrode 3 that purity is 99.9wt%, area 1dm respectively 2 , the two electrodes are separated by a secondary amine anion membrane 4, and the distance between the anode and the cathode and the ion membrane is 3 cm, forming an anode chamber and a cathode chamber respectively. Add 150.0g of 70wt% methanesulfonic acid aqueous solution and 50.0g of water to the anode chamber, and 150.0g of 70wt% methanesulfonic acid aqueous solution and 50.0g of water into the cathode chamber, and electrolyze with 10A constant current. The tin electrode of the anode is gradually reduced, and hydrogen gas is produced at the cathode. After electrolysis for a while, take a small amount of anolyte and titrate it with calibrated sodium hydroxide solution until ...

Embodiment 2-4

[0017] Embodiment 2-4: select tin electrodes of different shapes according to Table 1, wherein in granular tin and powder tin electrolysis devices, plate-shaped graphite current collectors are added, other experimental devices and process parameters are the same as in Example 1, and the electrolysis results are shown in Table 1 Show.

[0018] Table 1 Comparison table of different forms of tin electrodes

[0019] Example

[0020] The results showed that there was no significant difference in the electrolysis of various electrode configurations.

Embodiment 5-10

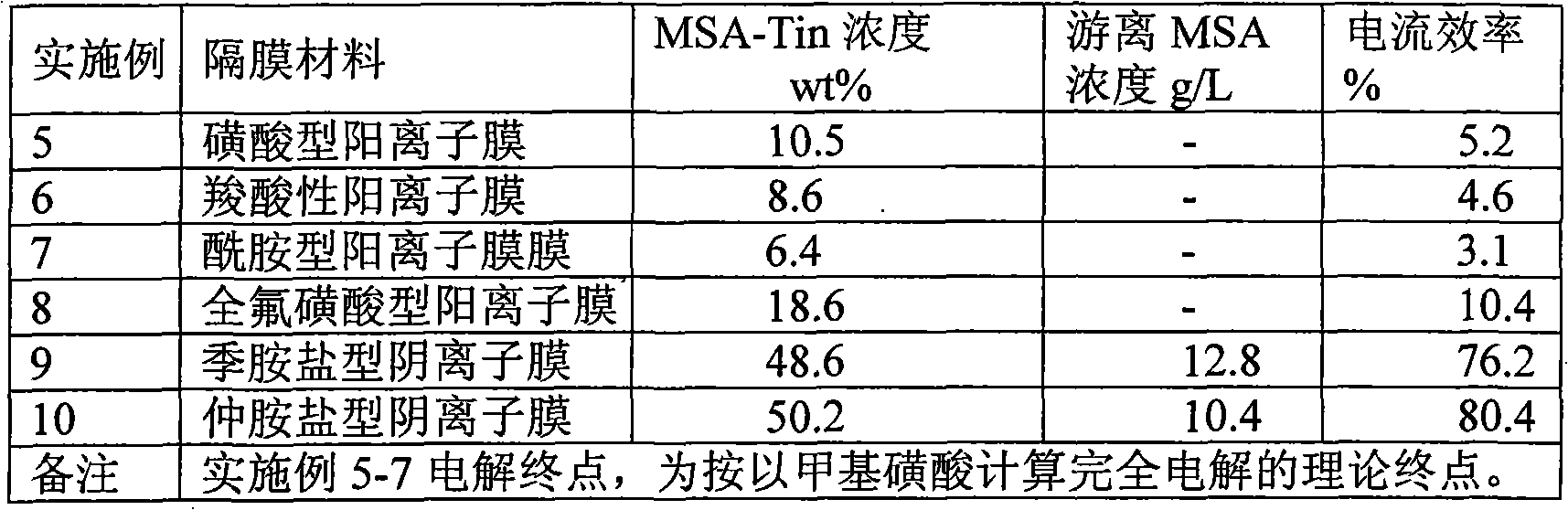

[0021] Examples 5-10: According to Table 2, different ion-exchange membranes were selected as diaphragm materials. Other experimental devices and process parameters were the same as in Example 1. The electrolysis results are shown in Table 2.

[0022] Table 2 Comparison table of different ion exchange membrane tests

[0023]

[0024] The results show that both anionic membrane and cationic membrane electrolysis can be carried out, but the anionic membrane has a better effect than the cationic membrane, and the effect of the quaternary ammonium salt anionic membrane and the secondary ammonium salt anionic membrane is better, and the obtained product concentration High, high current efficiency.

[0025] Examples 11-16: According to Table 3, different current densities were used for electrolysis, other experimental devices and process parameters were the same as in Example 1, and the electrolysis results are shown in Table 3.

[0026] Table 3 Comparison table of different cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com