Magnetic-particle photocatalyst with core-shell structure, preparation and application thereof

A photocatalyst and magnetic particle technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, inorganic material magnetism, etc. Inefficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

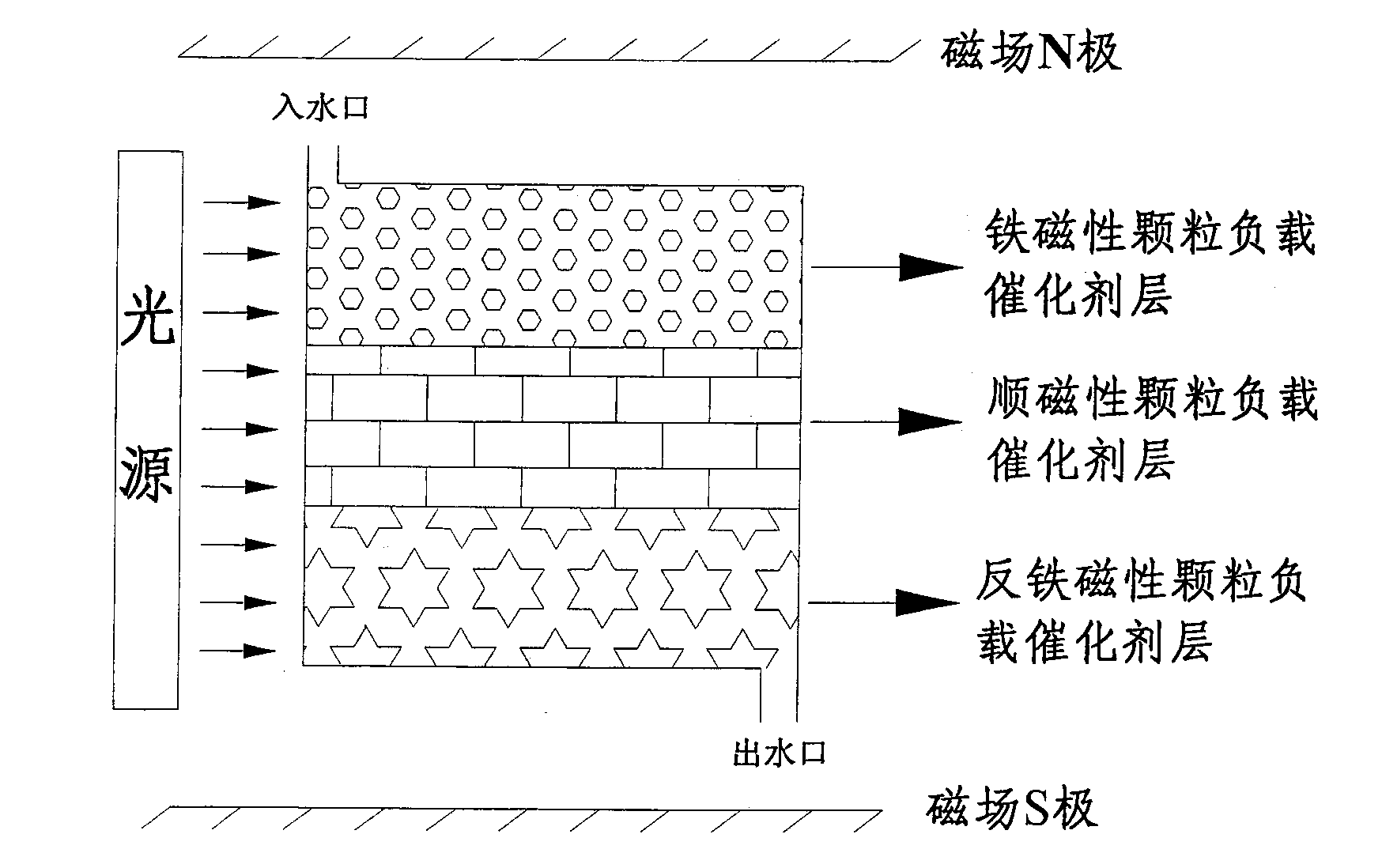

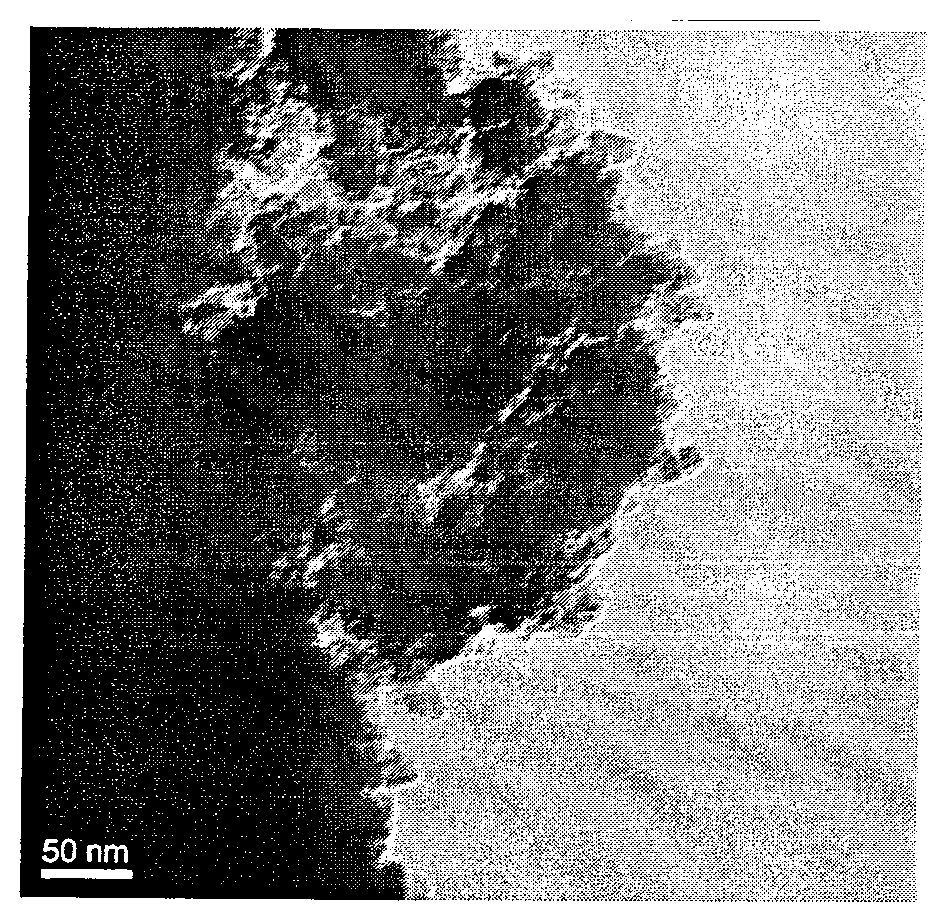

[0069] The core (magnetic particles)-shell (new catalyst) composite catalyst particles were prepared by pulsed laser sputtering deposition method or multi-target magnetron sputtering method, and γ-Fe 2 o 3 (Ferromagnetic particle core)-Gd 3-x Bi x SbO 7 (0.5≤x≤1) (photocatalyst shell), γ-Fe 2 o 3 (Ferromagnetic particle core)-Gd 3-x Y x SbO 7 (0.5≤x≤1) (photocatalyst shell), γ-Fe 2 o 3 (Ferromagnetic particle core)-In 3-x Bi x TaO 7 (0.5≤x≤1) (photocatalyst shell), SiO 2 (paramagnetic particle core)-Gd 3-x Bi x SbO 7 (0.5≤x≤1) (photocatalyst shell), SiO 2 (paramagnetic particle core)-Gd 3-x Y x SbO 7 (0.5≤x≤1) (photocatalyst shell), SiO 2 (paramagnetic particle core)-In 3-x Bi x TaO 7 (0.5≤x≤1) (photocatalyst shell), MnO (antiferromagnetic particle core)-Gd 3-x Bi x SbO 7 (0.5≤x≤1) (photocatalyst shell), MnO (antiferromagnetic particle core)-Gd 3-x Y x SbO 7 (0.5≤x≤1) (photocatalyst shell), MnO (antiferromagnetic particle core)-In 3-x Bi x TaO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com