Production method of cellulose ethanol

A technology of cellulosic ethanol and production methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as low fermentation efficiency, low ethanol yield, and reduced enzymatic hydrolysis effect, and achieve tolerance Strong, high rate and yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

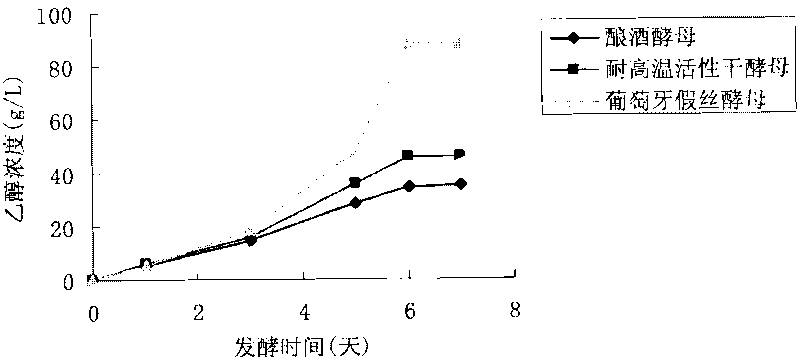

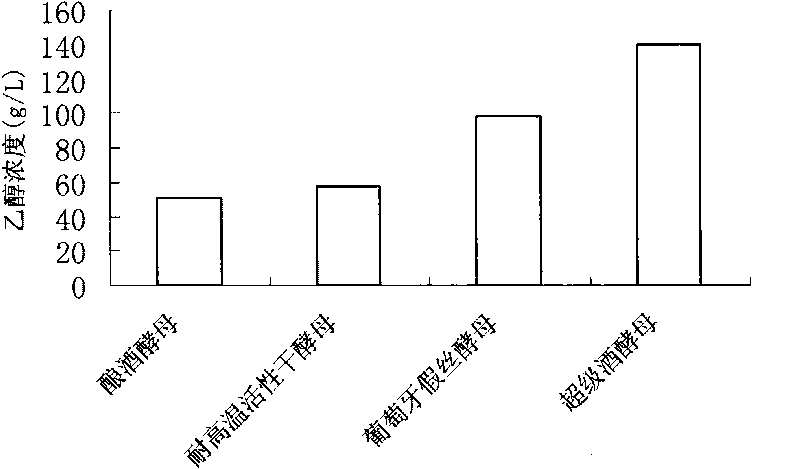

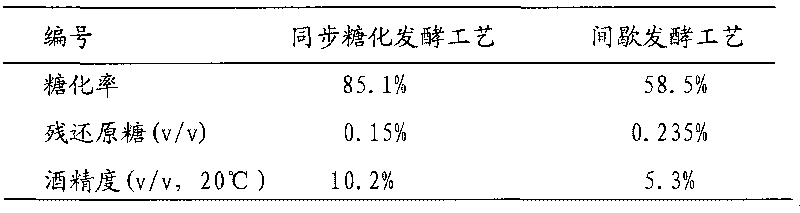

preparation example 1

[0046] Add the cellulose-containing medium to a 6L reactor containing 2L of water, and the sample volume reaches 2.5L to ensure that there is enough space for inoculation. The medium was mixed in a fermenter, containing lipid material (30ml / L oleic acid), and sterilized at 120°C for 30 to 40min. Antibiotics contain 500mg of 10mg / L penicillin and 500mg (10mg / L) of streptomcycin, pH at 4.5-5.0. Next, add cellulase, inoculate cellulosic ethanol yeast CLAS 5566, cell density 2X10 7 , diluted to 3L, diluted with water. The enzyme breaks down the cellulose into glucose and cellobiose, and the yeast ferments it into ethanol. The temperature is controlled at 38°C, and the simultaneous saccharification and fermentation is carried out for 72 hours to obtain 89g / L ethanol. Then, the ethanol is fractionally distilled from the fermentation substrate to obtain cellulosic ethanol.

preparation example 2

[0048] Add the cellulose-containing medium to a 20L reactor containing 4L of water, and the loading volume reaches 5.5L to ensure that there is enough space for inoculation. The medium was mixed in a fermenter, containing lipids (ergosterol 5 mg / L), and sterilized at 120 °C for 30 to 40 min. Antibiotics contain 500mg of 10mg / L penicillin and 500mg (10mg / L) of streptomcycin, pH at 4.0-4.5. Next, add cellulase, inoculate cellulosic ethanol yeast CLAS 5566, cell density 2X10 8 , diluted to 5L, diluted with water. The enzyme breaks down the cellulose into glucose and cellobiose, and the yeast ferments it into ethanol. The temperature is controlled at 42°C, and the simultaneous saccharification and fermentation is carried out for 96 hours to obtain 98g / L ethanol. Then, the ethanol is fractionally distilled from the fermentation substrate to obtain cellulosic ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com