Solid material microwave-sterilizing method and tubular device thereof

A material and solid-state technology, which is applied in the field of microwave sterilization of solid-state materials and their tubular devices, can solve the problems of complex processes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

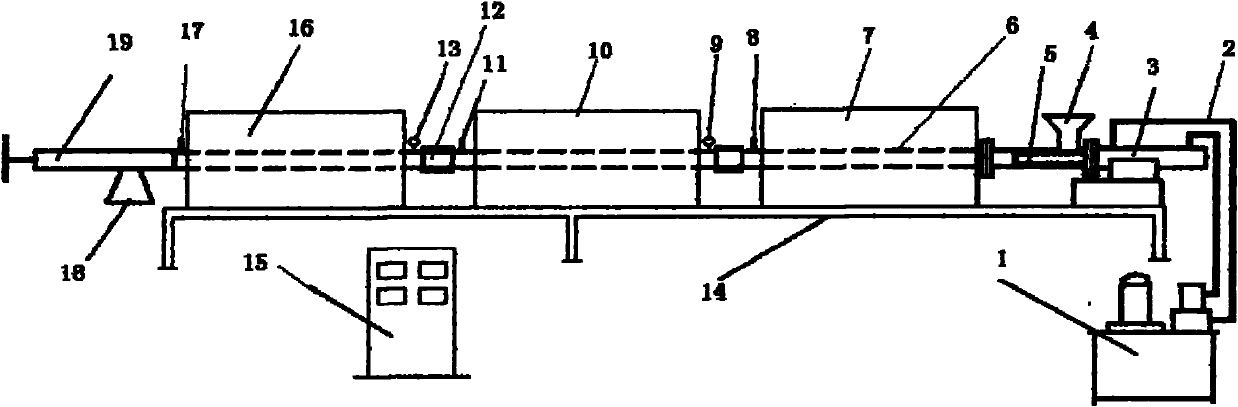

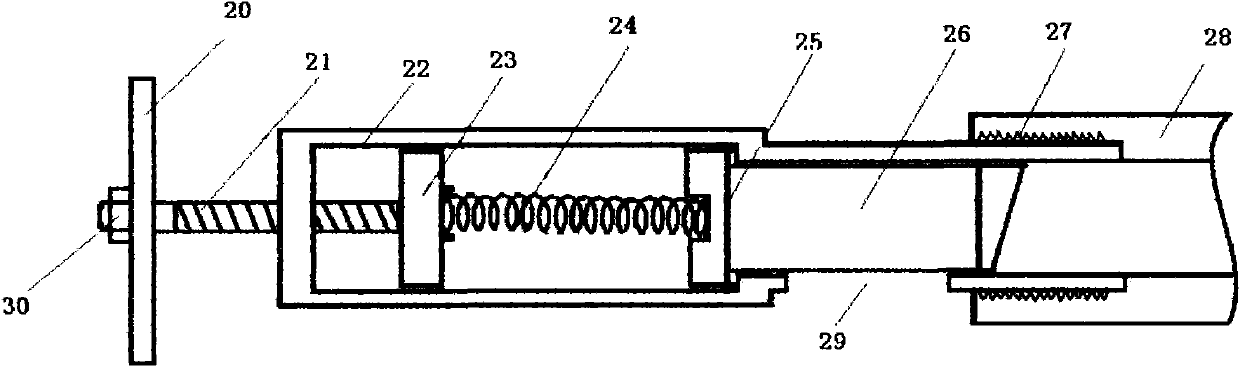

[0023] The tubular microwave continuous heating and sterilizing solid material device is composed of a pressurized solid material conveying system, a microwave heating system and an automatic control system. Among them, the solid material conveying system consists of hydraulic or pneumatic pressure station (1), pressure pipe (2), hydraulic cylinder or pneumatic cylinder (3), feeding port (4), push rod (5), feeding pipe (6) , discharge port (18), spring sealing valve (19), composed; the heating system is mainly composed of an array of graded heating microwave ovens, preheating microwave ovens (7), main heating microwave ovens (10), and heat preservation heating microwave ovens (16); the control system Mainly by the first temperature sensor (8), the first pressure sensor (9), the second temperature sensor (11), the second pressure sensor (13), the third temperature sensor (17) and The relevant control device (15) is composed, and the control mode can be controlled in a simple wa...

Embodiment 2

[0029] In the production process of solid-state fermentation to produce red yeast rice, protease, pectinase, cellulase, citric acid, ethanol, lactic acid, gibberellin, vitamins, soy sauce, vinegar, liquor, protein feed, b.t. preparations, edible fungi, etc. , the medium for solid-state fermentation needs to be sterilized. With the present invention, the solid material to be sterilized is fed through the feeding port (4) of the tubular microwave continuous heating and sterilizing solid material device, and pushed into the feeding pipe (6) through the push rod (5). Under the push of the push rod, the solid material enters the delivery pipe from the feed port and is pushed to the discharge port. The heating and sterilization capacity of the solid material is controlled by the advancing rate. The discharge end is connected with the spring sealing valve, which can control the material While ensuring the continuous output of the material, there is sufficient sterilization temperatur...

Embodiment 3

[0031] According to the present invention, during the extraction process of active ingredients of Chinese herbal medicines, such as resveratrol, ginsenosides, ephedrine, glycyrrhizic acid, shikonin, etc., the raw grass powder is sprayed and pre-wetted and placed for 5-30 minutes. Minutes, the amount of water sprayed depends on the relevant extraction process. Water spray pre-wetting can make the grass powder be heated rapidly when it is microwaved, and at the same time, the structure of the grass powder can be damaged by microwaves.

[0032] Push the solid material of Chinese herbal medicine powder to be processed by microwave into the feeding pipe (6) through the push rod (5) through the feeding port (4), and the solid material enters the feeding pipe from the feeding port under the push of the push rod and is pushed forward Running to the discharge port, the processing temperature and processing time can be adjusted by the microwave heating power and the material propulsion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com