Diesel composition

A kind of diesel oil composition and diesel oil technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of poor oxidation stability and detergency, poor stability and detergency dispersibility, etc., and achieve good stability and detergency dispersibility , anti-oxidation and detergency dispersibility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

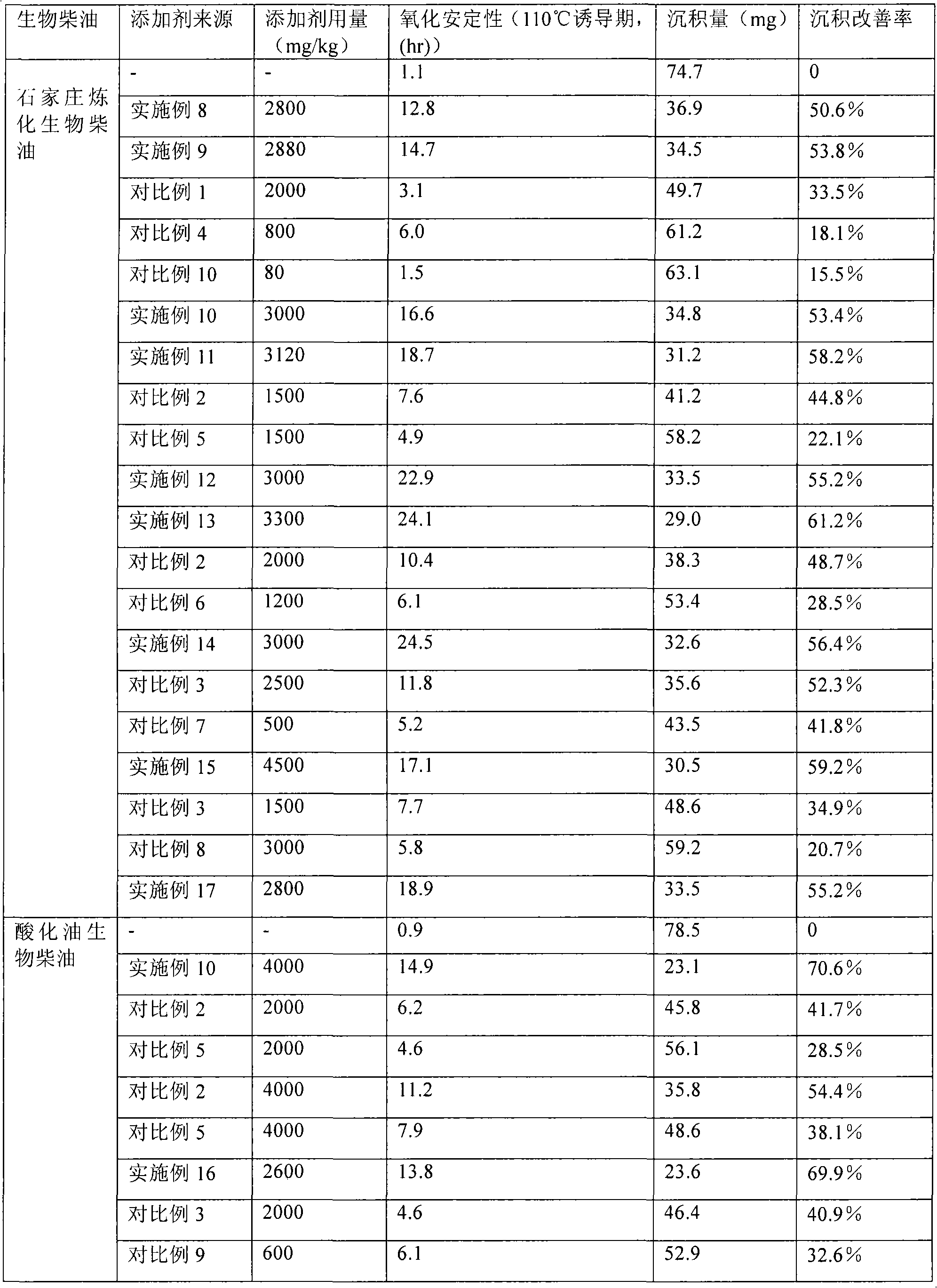

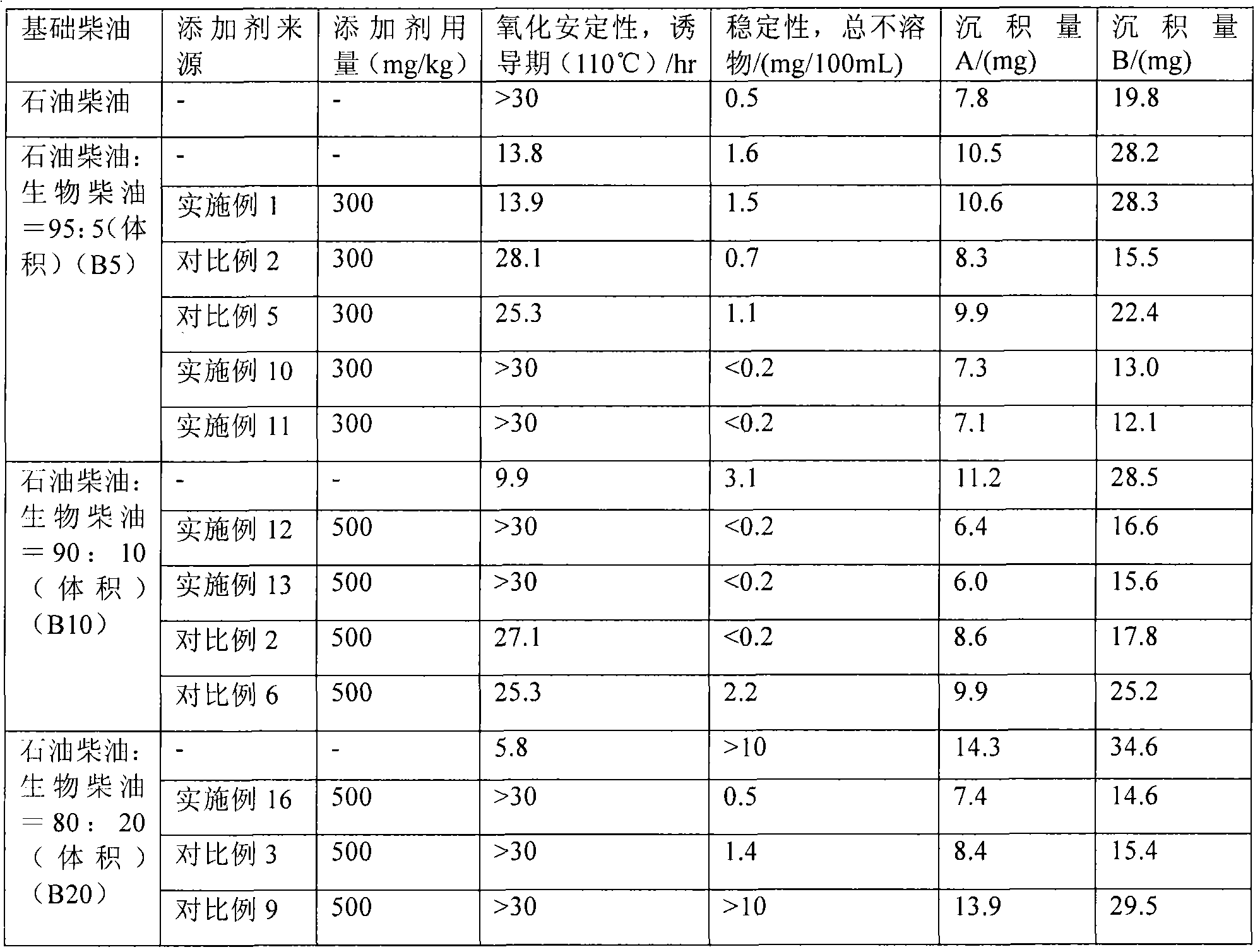

Examples

preparation example Construction

[0167] The preparation of the diesel composition provided by the invention is simple, and only needs to mix the components of the diesel composition uniformly. The various additive components can be directly mixed with the base diesel oil, or the various additive components can be mixed evenly first to obtain the additives, and then the obtained additives can be mixed with the base diesel oil. For the convenience of operation, when the various additive components are mixed uniformly, it can be carried out in the presence of a solvent, and the solvent here can be a polar solvent such as N, N-dimethylformamide (DMF), 1,4-dioxane One or more of ring, tetrahydrofuran (DHF), dimethyl sulfoxide (DMSO), pyrrolidone and methylpyrrolidone. It can also be hydrocarbons, especially aromatics such as benzene, toluene, xylene, aromatics diluent oil and their mixtures, and biodiesel.

[0168] In the diesel composition of the present invention, the base diesel is biodiesel. Described biodie...

Embodiment 1

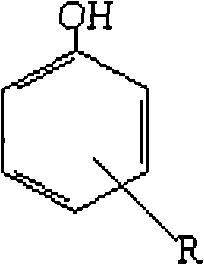

[0180] In a 1000ml three-necked bottle, add 363.3 grams of polyisobutene (the number-average molecular weight of polyisobutene Mn=1100, the source is Jinzhou Petrochemical Company) and 62.1 grams of phenol, stir and heat to 50 ° C, and 14.1 grams of BF 3 - Diethyl ether solution was added dropwise to the reaction system three times in about two hours. The temperature was raised to 60°C, and the reaction was timed for 4.5 hours. Stop the reaction, wash with 40°C distilled water three times, and then distill under reduced pressure to remove unreacted phenol. The unreacted polyisobutene was analyzed by column chromatography to be 32%, and the alkylation conversion rate of polyisobutene was calculated to be 68%.

Embodiment 2

[0182] In a 500ml three-necked bottle, add 100 grams of polyisobutene (polyisobutene number-average molecular weight Mn=1000, the source is BASF, Germany) and 18.8 grams of phenol, stir and heat to 60 ° C, and 4.3 grams of BF 3 - Diethyl ether solution was added dropwise to the reaction system three times in about two hours. The temperature was raised to 70°C, and the reaction was timed for 4 hours. Stop the reaction, wash with 50°C distilled water three times, and then distill off unreacted phenol under reduced pressure. The unreacted polyisobutene was analyzed by column chromatography to be 30%, and the alkylation conversion rate of polyisobutene was calculated to be 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com