Cationic photo-cured fluorine-containing organosilicon composite coating and preparation method thereof

A composite coating, cationic technology, applied in the field of coatings, can solve the problems of difficult to achieve high performance requirements of coatings, limited application scope of materials, poor compatibility of coating components, etc., to achieve good flexibility, prevent volatilization, and increase compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

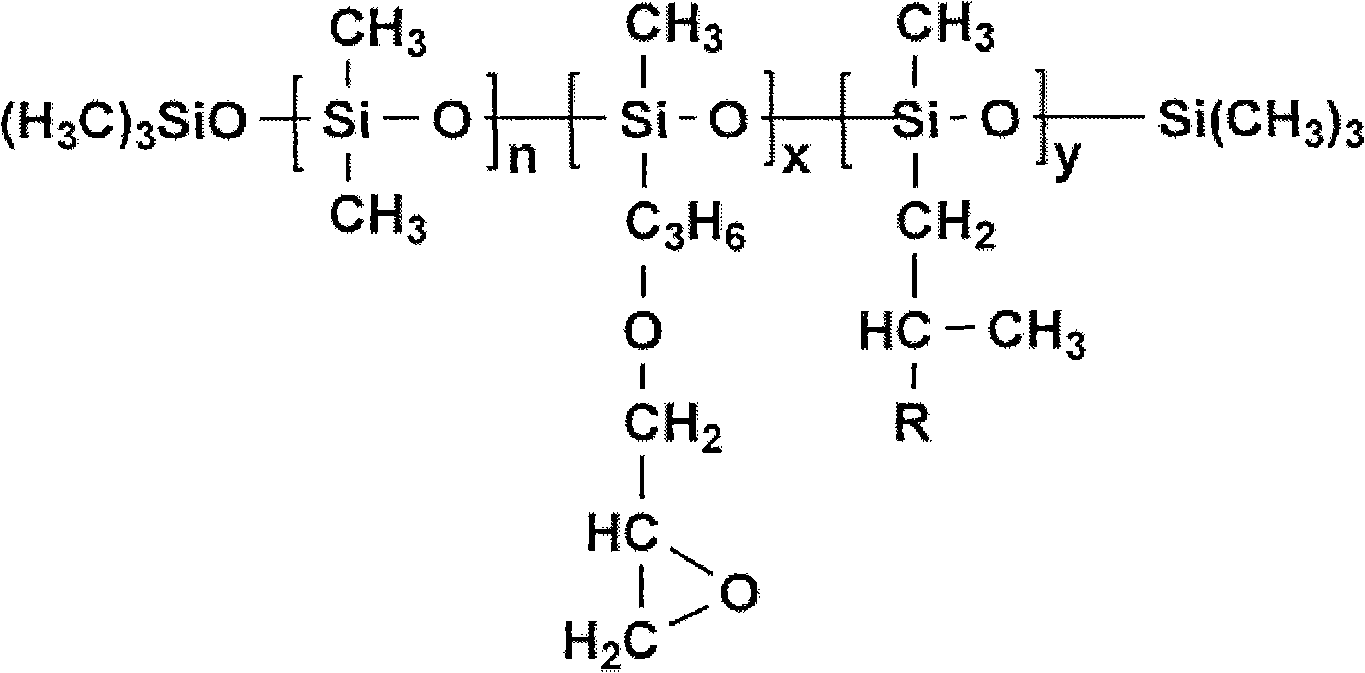

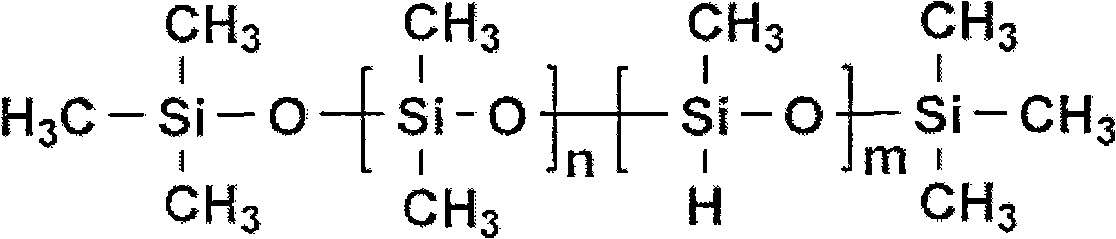

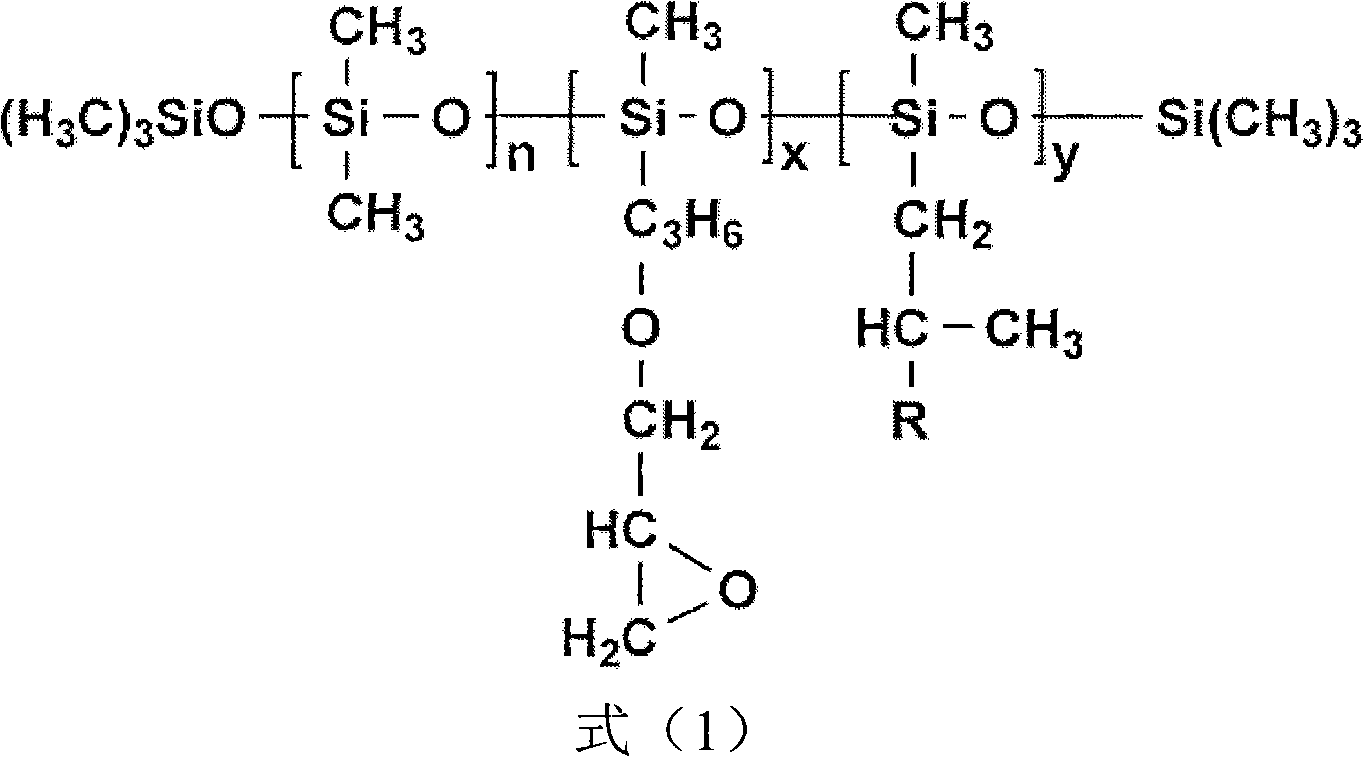

[0037] (1) 100 parts by weight of hydrogen-containing silicone oil (hydrogen content 0.18%), 22 parts of dodecafluoroheptyl methacrylate and 120 parts of toluene are loaded into a reactor equipped with a stirrer, dropping funnel and thermometer, Under the protection of nitrogen, heat and stir to 120°C, then add 0.013 parts of chloroplatinic acid catalyst, react for 4 hours; then add 15 parts of allyl glycidyl ether at 90°C, react for 4 hours, and remove the solvent under reduced pressure and unreacted substances to obtain cationic photocurable silicone.

[0038] IR test analysis results: Si-H characteristic absorption peak of raw material (2160cm -1 ) disappears; the characteristic absorption peak of cationic photocurable silicone appears: C=O (1720cm -1 ), C-F (1185cm -1 ), Si-CH 3 (1260cm -1 , 800cm -1 ), Si-O-Si (1018-1099cm -1 ), epoxy (910cm -1 ).

[0039] (2) 30 parts by weight of cationic photocurable silicone are added to the container; then 100 parts of bisphe...

Embodiment 2

[0042] (1) 100 parts by weight of hydrogen-containing silicone oil (hydrogen content 0.22%), 26 parts of hexafluorobutyl acrylate and 120 parts of toluene are packed into a reactor equipped with a stirrer, dropping funnel and thermometer, under nitrogen protection Heat and stir to 110°C, then add 0.015 parts of chloroplatinic acid catalyst, react for 3.5 hours; then add 13 parts of allyl glycidyl ether at 85°C, react for 5 hours, remove the solvent and unreacted Products, the preparation of cationic light-curable silicone.

[0043] (2) First add 50 parts by weight of cationic photocurable silicone into the container; then add 100 parts of bisphenol A epoxy resin E-51, 50 parts of aliphatic epoxy polyethylene glycol diglycidyl ether, 5 parts Cationic photoinitiator triarylsulfonium salt, additives (1 part of leveling agent BYK-358, 1 part of defoamer BYK-055, 1 part of surface wetting agent BYK-2700), each time a reaction raw material is added, the After stirring evenly, the n...

Embodiment 3

[0046] (1) 100 parts by weight of hydrogen-containing silicone oil (hydrogen content 0.43%), 117 parts of hexafluorobutyl acrylate and 200 parts of toluene are packed into a reactor equipped with a stirrer, dropping funnel and thermometer, under nitrogen protection Heat and stir at 116°C, then add 0.05 parts of chloroplatinic acid catalyst, react for 5 hours; then add 15 parts of allyl glycidyl ether at 85°C, react for 4 hours, remove the solvent and unreacted Products, the preparation of cationic light-curable silicone.

[0047](2) First add 20 parts by weight of cationic photocurable silicone into the container; then add 50 parts of bisphenol A epoxy resin E-54, 2 parts of cationic photoinitiator diaryliodonium salt, auxiliary agent (0.2 1 part of leveling agent BYK-306, 0.3 part of defoamer BYK-080, 0.5 part of surface wetting agent BYK-2700), each time a reaction raw material is added, it is stirred evenly, and then the next reaction raw material is added until The compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com