BiVO4 nano photoelectrode and application thereof in hydrogen production from water splitting

A nano-light and electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of only 490nm light response range and low quantum efficiency, and achieve the effect of easy mass production, simple preparation method and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

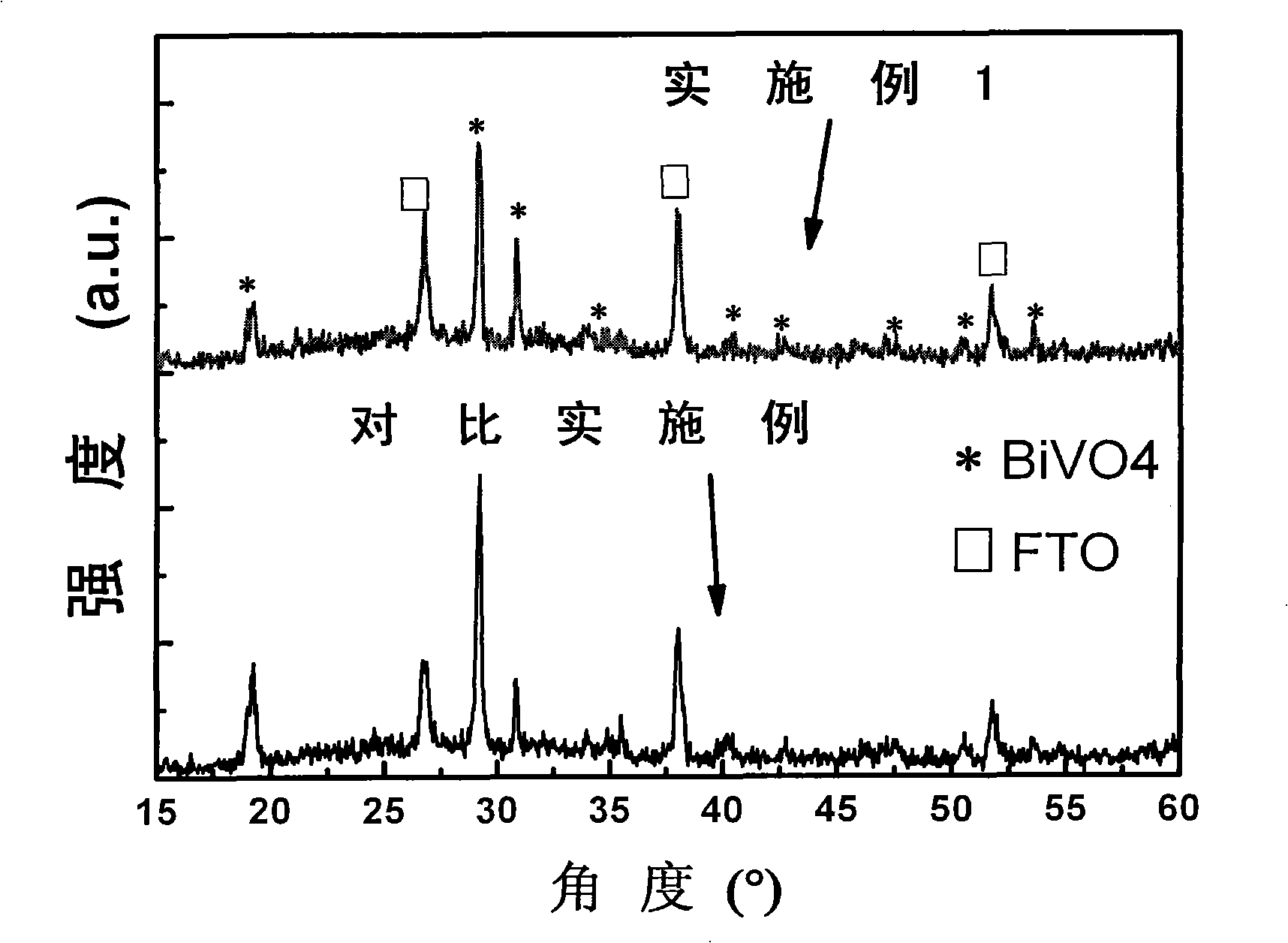

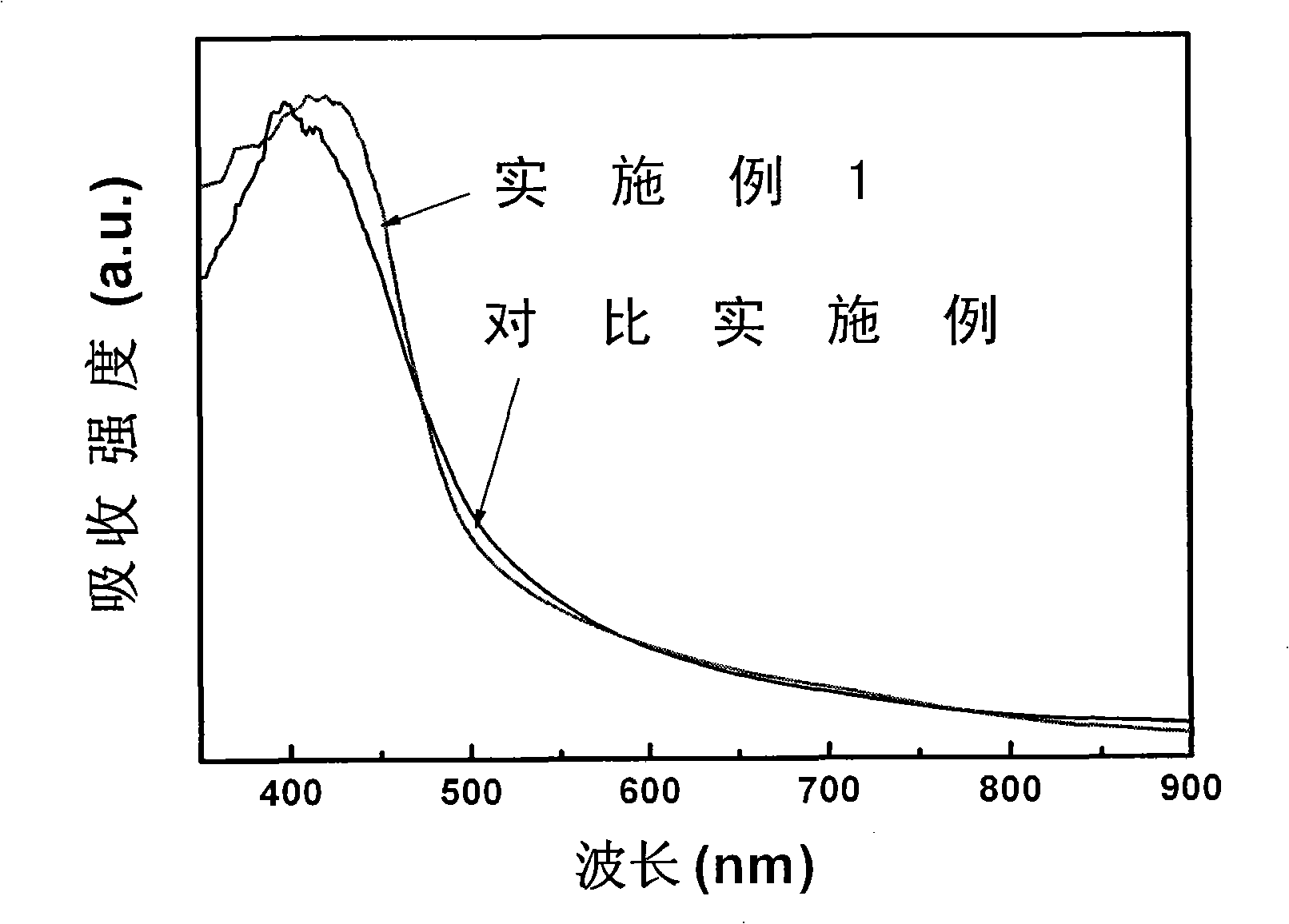

Embodiment 1

[0032] Step 1. with the glacial acetic acid solution of 0.2mol / L bismuth nitrate and the acetylacetone solution of 0.03mol / L vanadium acetylacetonate, the acetylacetone solution of 0.01mol / L molybdenum acetylacetonate, by Bi: (V+Mo) mol ratio 1 : 1 for mixing, the molar concentration of Mo ions accounted for 3% of Bi ions, and a clear solution was obtained.

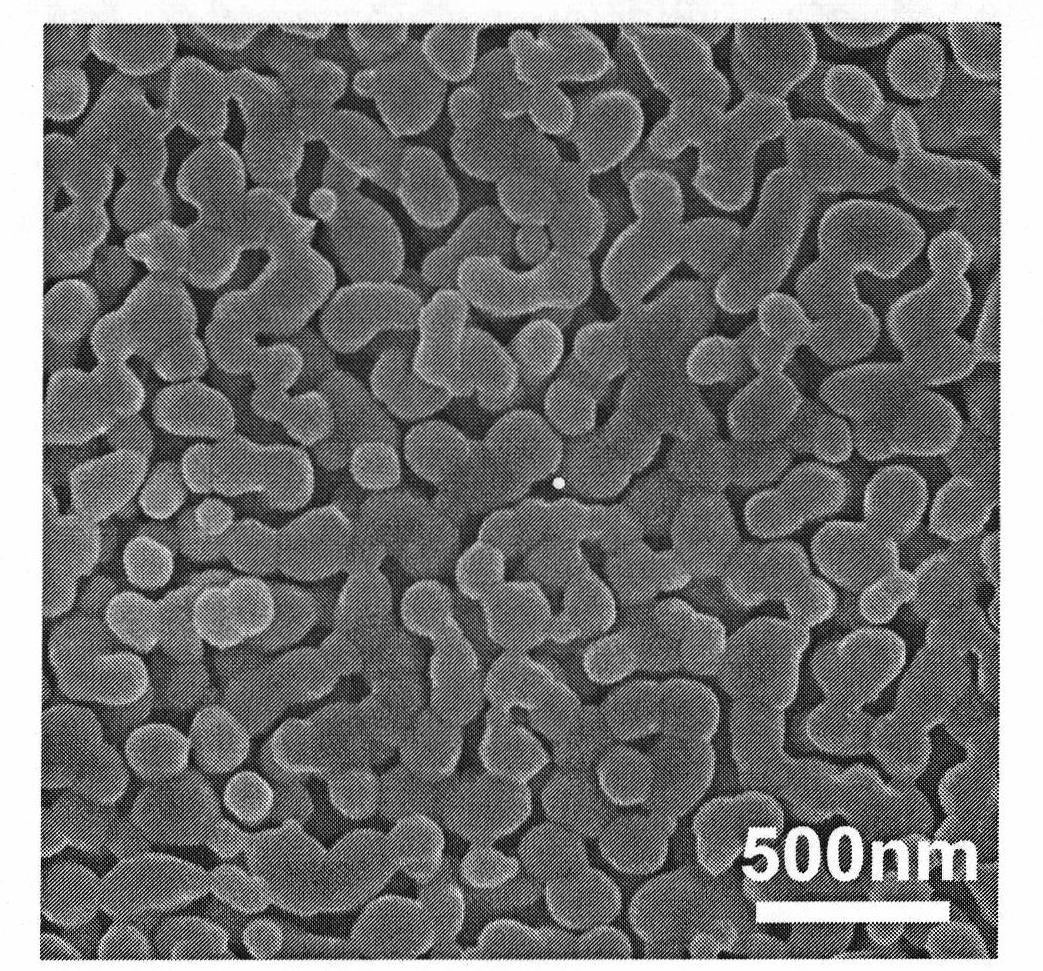

[0033] Step 2. Spin-coat the solution obtained in step 1 onto conductive glass (FTO), dry it at 150° C., and then calcinate it in air at 455° C. for 30 minutes to obtain a thin film. A nanoporous film with a thickness of 1 micron can be obtained by repeating the above operation 4 times.

[0034] Mo-doped BiVO was obtained through the above steps 4 Nano photoelectrode.

Embodiment 2

[0036] The cocatalyst Co was impregnated 3 o 4 Loaded on the Mo-doped BiVO obtained in Example 1 4 The surface of the nanometer photoelectrode was baked at 300°C for 2 hours to obtain the cocatalyst Co 3 o 4 Modified Mo-doped BiVO 4 Nano photoelectrode.

Embodiment 3

[0038] The cocatalyst Fe was impregnated 2 o 3 Loaded on the Mo-doped BiVO obtained in Example 1 4 The surface of the nanometer photoelectrode was baked at 300°C for 2 hours to obtain the cocatalyst Fe 2 o 3 Modified Mo-doped BiVO 4 Nano photoelectrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com