Cerium-europium-doped yttrium aluminum garnet and method for preparing phosphor powder from same

A technology of yttrium aluminum garnet and phosphor powder is applied in chemical instruments and methods, luminescent materials, rare earth metal compounds, etc., can solve problems such as increasing production cost, and achieve the effects of short reaction time, excellent optical performance and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1.35 g of yttrium nitrate, 7.50 g of aluminum nitrate, 0.0526 g of cerium nitrate, and 0.0416 g of europium nitrate were dissolved in deionized water, and 0.44 g of polyethylene glycol was added. The solution was placed in a sealed autoclave, heated to 180° C. under the action of magnetic stirring, and kept for 30 minutes to obtain a precursor solution. The obtained precursor solution was sintered in an air atmosphere at 900°C for 10 minutes, the obtained sample was cooled to room temperature, washed with acid and alcohol, and sieved through a 400-mesh sieve to obtain YAG:Ce 3+ , Eu 3+ Powder.

Embodiment 2

[0029] 1.35 g of yttrium nitrate, 7.50 g of aluminum nitrate, 0.2104 g of cerium nitrate, and 0.1248 g of europium nitrate were dissolved in deionized water, and 1.76 g of polyethylene glycol was added. The solution was placed in a sealed autoclave, heated to 300° C. under the action of magnetic stirring, and kept for 30 minutes to obtain a precursor solution. The obtained precursor solution was sintered in an air atmosphere at 1100°C for 90 minutes, the obtained sample was cooled to room temperature, washed with acid and alcohol, and sieved through a 400-mesh sieve to obtain YAG:Ce 3+ , Eu 3+ Powder.

Embodiment 3

[0031] 1.35 g of yttrium nitrate, 7.50 g of aluminum nitrate, 0.1052 g of cerium nitrate, and 0.0832 g of europium nitrate were dissolved in deionized water, and 0.88 g of polyethylene glycol was added. The solution was placed in a sealed autoclave, heated to 220° C. under the action of magnetic stirring, and kept for 30 minutes to obtain a precursor solution. The obtained precursor solution was sintered in an air atmosphere at 1000°C for 40 minutes, the obtained sample was cooled to room temperature, washed with acid and alcohol, and sieved through a 400-mesh sieve to obtain YAG:Ce 3+ , Eu 3+ Powder.

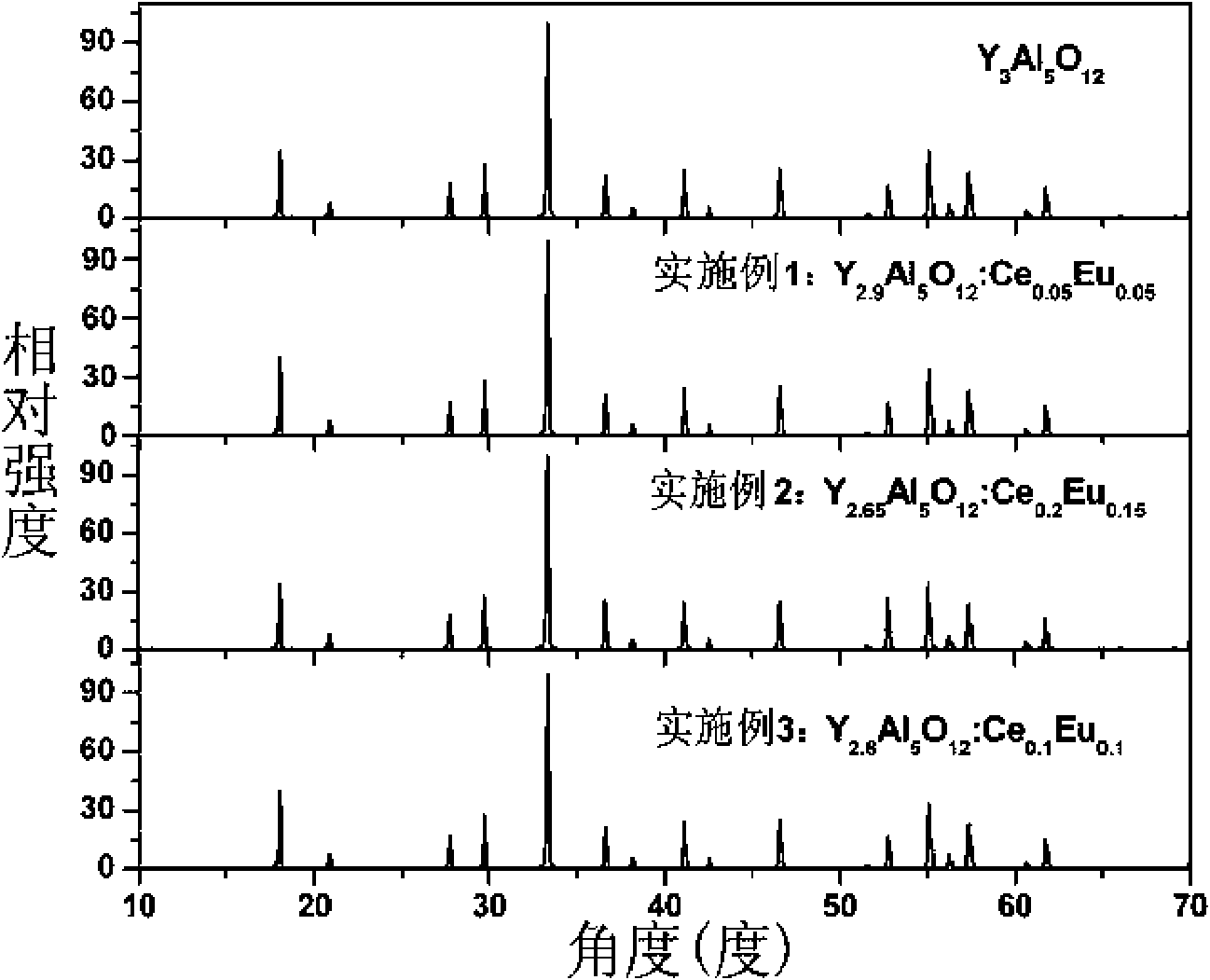

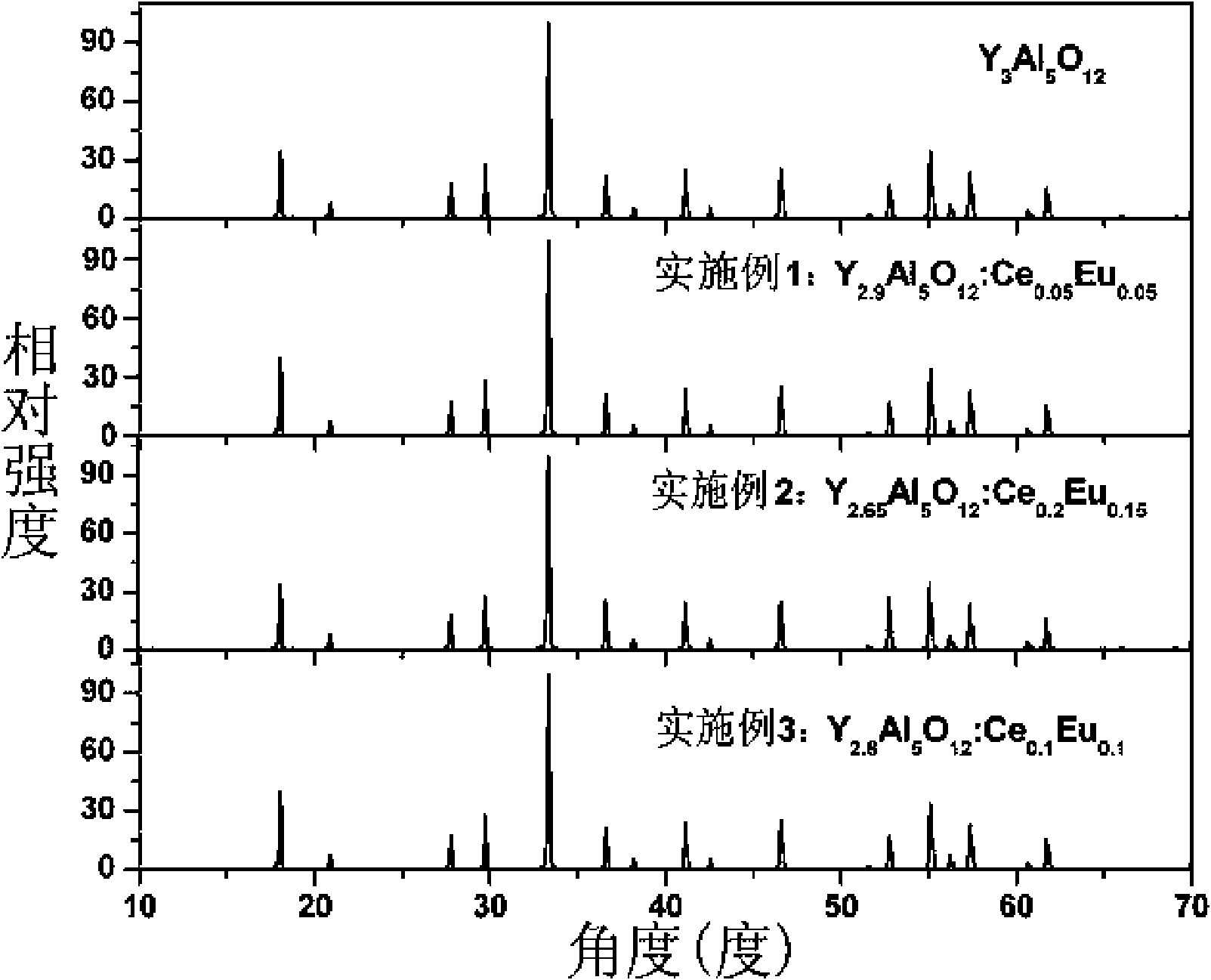

[0032] Depend on figure 1 It can be seen that the doping mole percentage in YAG is 5%-20%Ce 3+ and 5%-15% by mole of Eu 3+ The basic structure of the substance will not be changed, and the xrd patterns of the samples of the three groups of examples can all correspond to the xrd patterns of the standard YAG.

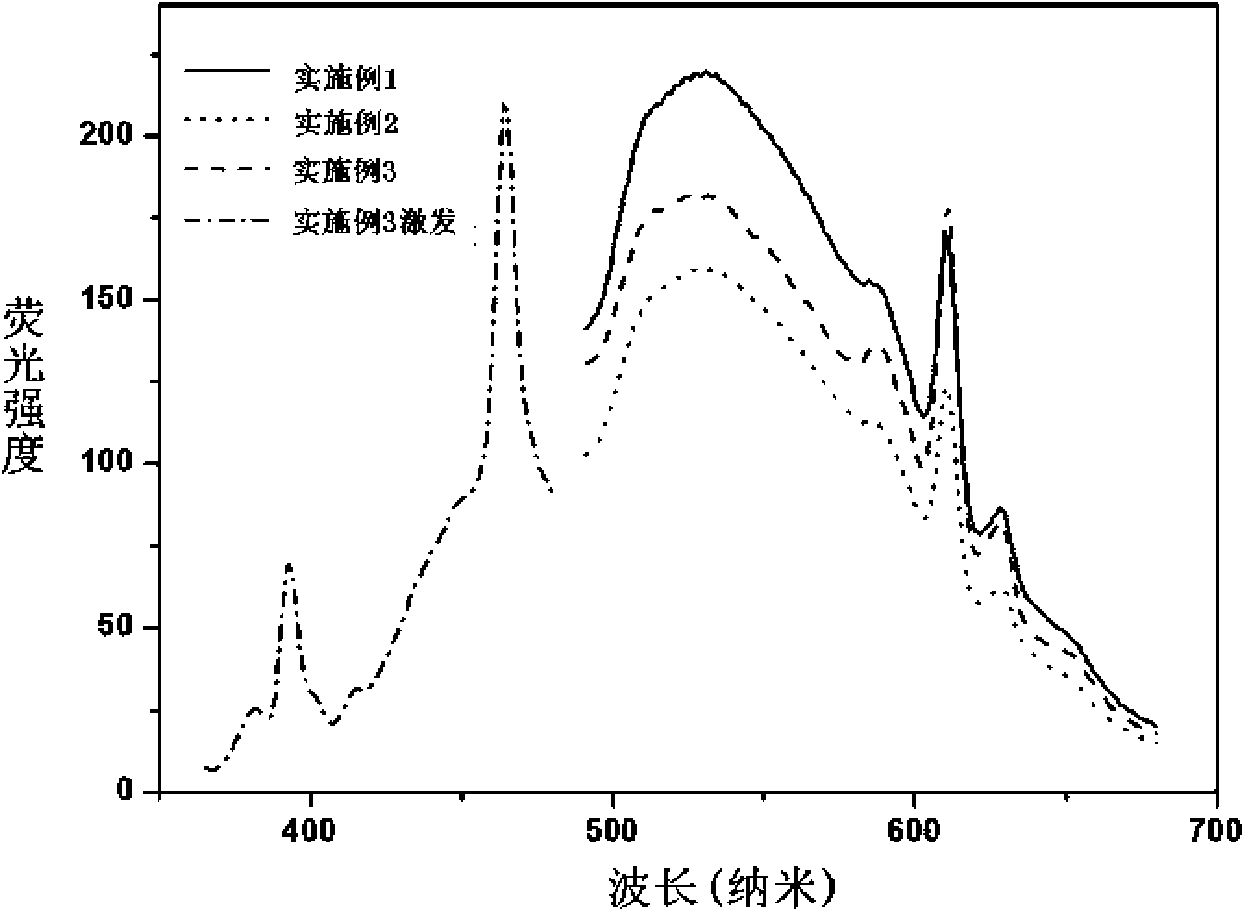

[0033] Depend on figure 2 It can be seen that doping different...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com