Oil extraction wastewater treatment method used for oilfield reinjection

A technology of oil production sewage and treatment method, which is applied in the treatment of waste water or sewage, water field, can solve the problems of high total cost, strong corrosion, impact on ecology, etc., and achieve the effect of low treatment cost, high treatment efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Taking the treatment of 1000mL oil extraction wastewater as an example, the raw materials and treatment methods used are as follows:

[0027] 1. Desulfurization and iron removal

[0028] Take 1000mL of oil production sewage at 30-60°C, add 240mg of a 30% composite aqueous solution prepared by hydrogen peroxide and sodium hypochlorite at a mass ratio of 1:4, and stir for 5 minutes.

[0029] 2. Adjust the pH value

[0030] Add a compound composed of CaO and NaOH at a mass ratio of 1:2 to the water after desulfurization and iron removal in step 1, and adjust the pH value to 7.5.

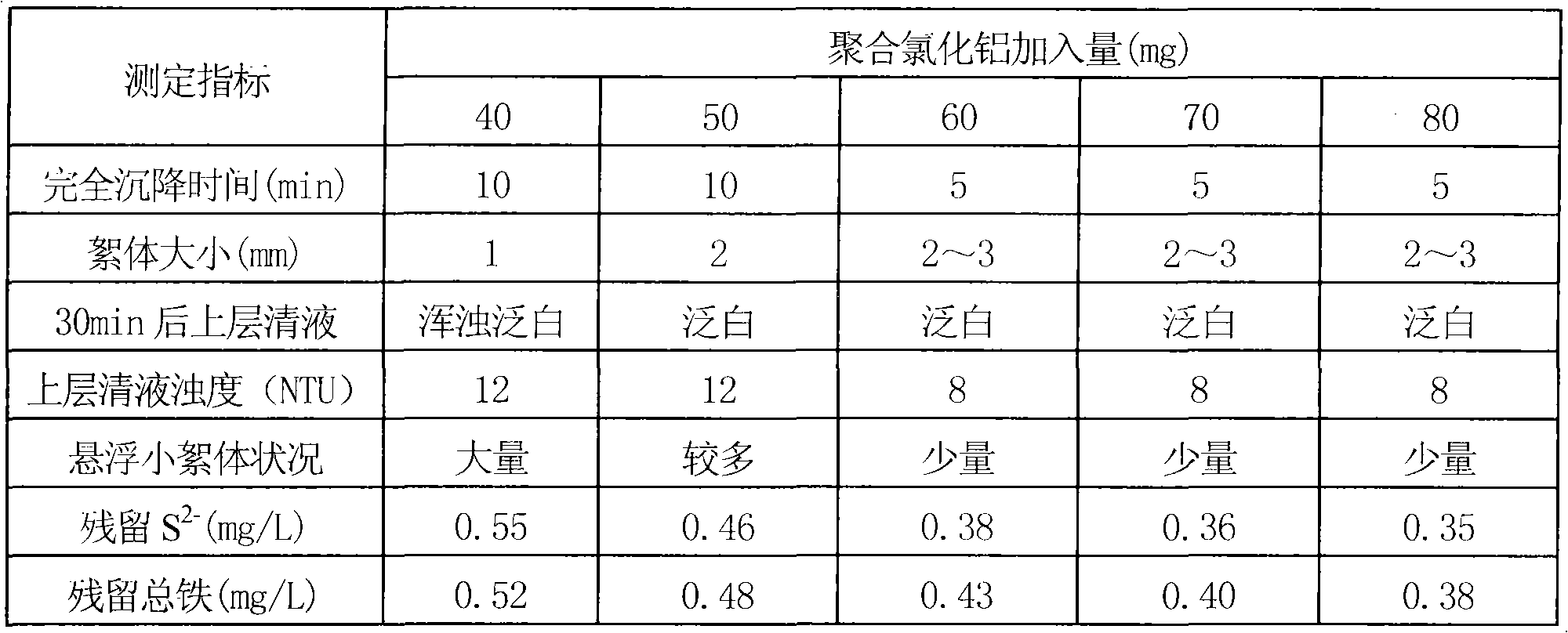

[0031] 3. Coagulation to remove oil and suspended particles

[0032] Add 60 mg of polyaluminum chloride to the water after pH adjustment in step 2, and stir for 5 minutes.

[0033] Al in the above-mentioned polyaluminum chloride 2 o 3 The content is higher than 27%, the basicity is 45%-95%, and the mass percentage of water-insoluble matter in 1% aqueous solution is lower than 2%. It is produ...

Embodiment 2

[0037] Taking the treatment of 1000mL oil extraction wastewater as an example, the raw materials and treatment methods used are as follows:

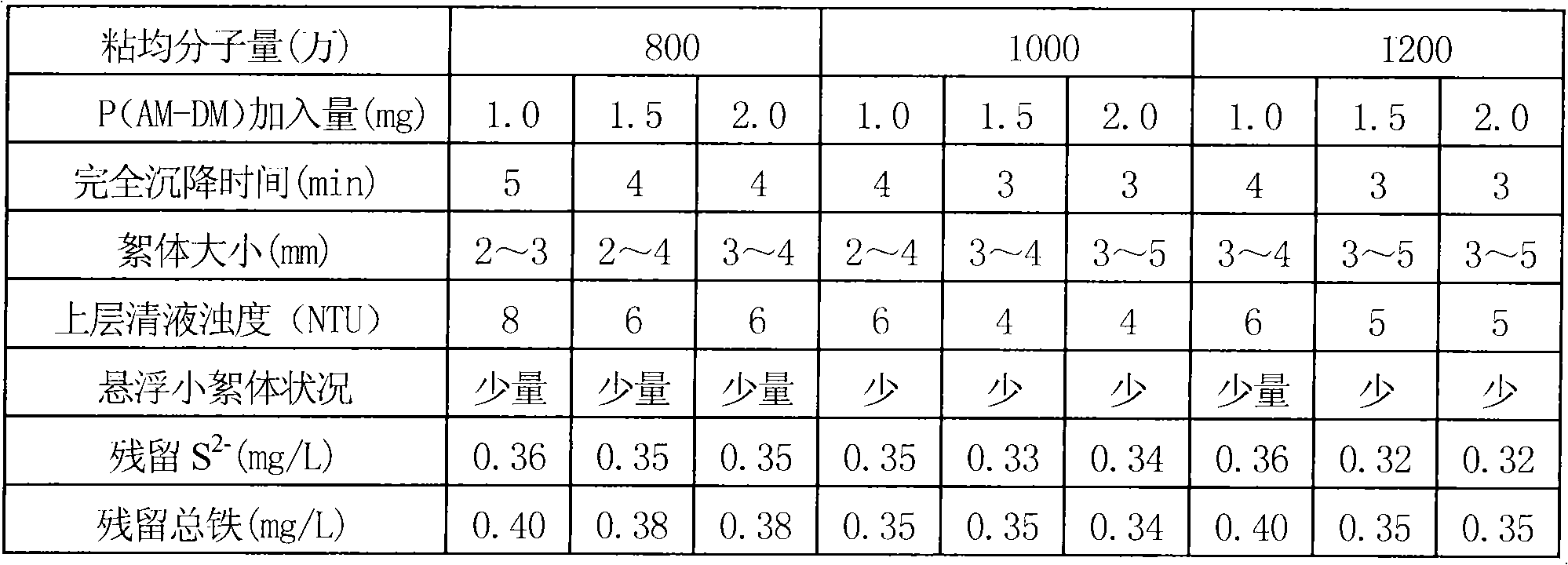

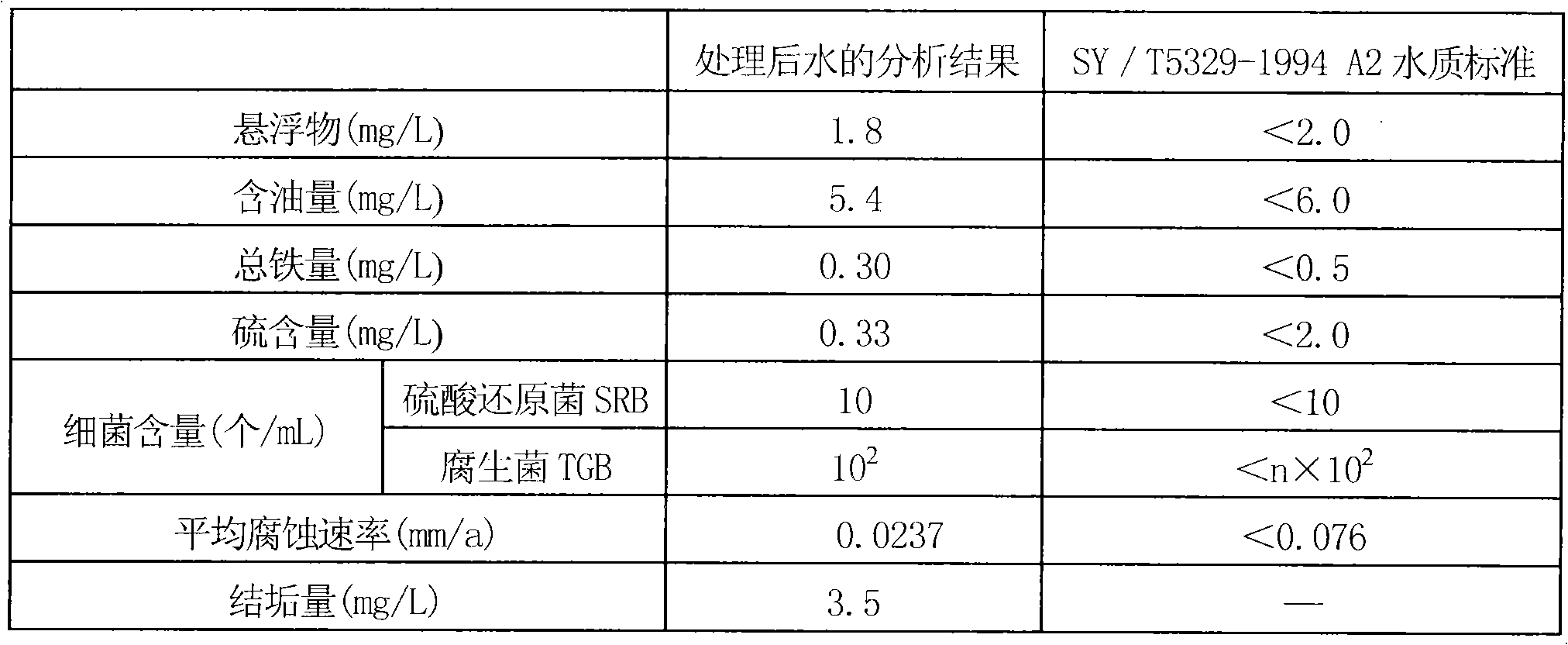

[0038] In the desulfurization and iron removal step 1 of the present embodiment, 200 mg of a 30% composite aqueous solution prepared by adding hydrogen peroxide and sodium hypochlorite in a mass ratio of 1:4 is used. Other steps of this step are the same as in Example 1. In step 3 of coagulation and degreasing and suspended particles, 40 mg of polyaluminum chloride was added to the water after the pH value was adjusted in step 2, and other steps of this step were the same as in Example 1. In the flocculation and sedimentation step 4, adding the copolymer 1.5 mg of dimethyl diallyl ammonium chloride and acrylamide with a viscosity-average molecular weight of 10 million to the water after coagulation and degreasing and suspended particles in step 3, the step Other steps are identical with embodiment 1. Other steps are identical with embod...

Embodiment 3

[0040] Taking the treatment of 1000mL oil extraction wastewater as an example, the raw materials and treatment methods used are as follows:

[0041]In the desulfurization and iron removal step 1 of the present embodiment, 300 mg of a composite aqueous solution with a mass fraction of 30% prepared by adding hydrogen peroxide and sodium hypochlorite in a mass ratio of 1:4, other steps of this step are the same as in Example 1. In step 3 of coagulation and degreasing and suspended particles, 80 mg of polyaluminium chloride was added to the water after the pH value was adjusted in step 2, and other steps of this step were the same as in Example 1. In the flocculation and sedimentation step 4, adding the copolymer 2mg of dimethyl diallyl ammonium chloride and acrylamide with a viscosity-average molecular weight of 10 million to the water after coagulation and degreasing and suspended particles in the step 3, other steps of the step Step is identical with embodiment 1. Other steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com