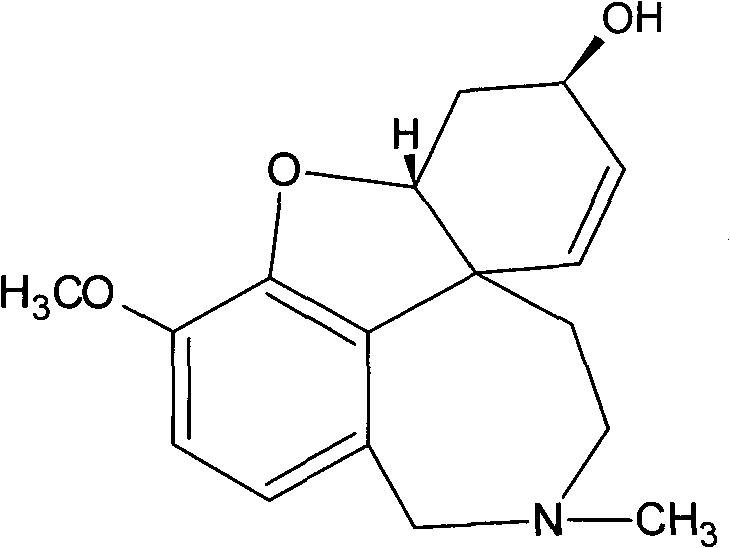

Method for extracting galanthamine from lycoris aurea

A technology of galantamine and galantamine hydrobromide, applied in organic chemistry and other directions, can solve the problems of insufficient drug market supply, weak market competitiveness, and cumbersome operation, so as to enhance market competitiveness and achieve good dissolution effect. , the effect of simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Extraction: Weigh 70g of Hudixiao dry powder, heat reflux extraction with 500ml methanol in a 2L extraction tank at 65°C for 2 hours, filter, and collect the filtrate; add 450ml methanol and heat reflux extraction in a 2L extraction tank at 65°C After 2 hours, filter and collect the filtrate; add 450ml of methanol and extract under reflux in a 2L extraction tank at 65°C for 2 hours, filter and collect the filtrate; combine 3 times to collect the extract. Concentrate under reduced pressure in a 1L round-bottomed flask at 40°C to 60°C with a rotary evaporator until there is no methanol to obtain the Hudixiao extract.

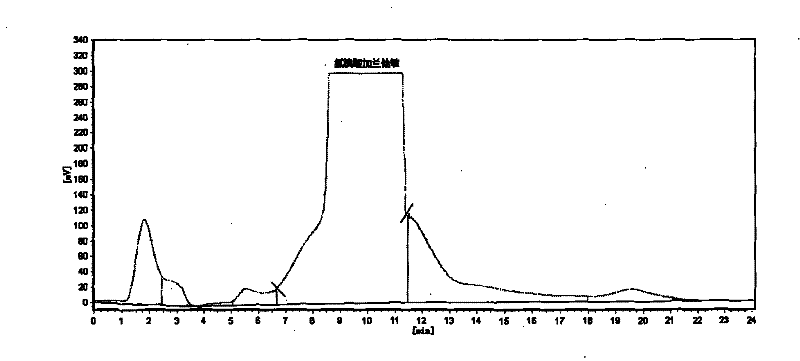

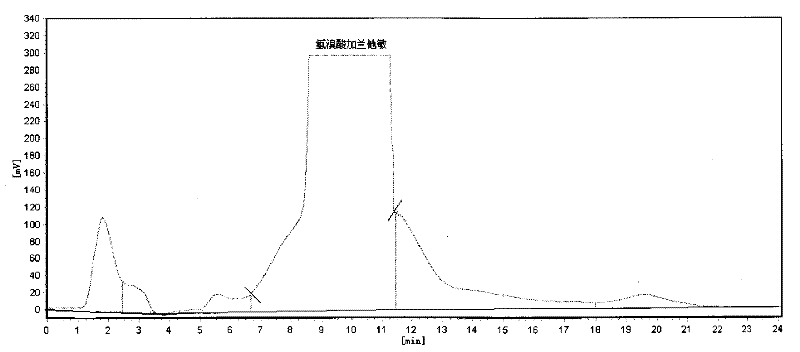

[0057] 2. Separation: Dissolve the Hudixiao extract with 150 times the volume of 2% acetic acid aqueous solution, stir fully, remove oily foam, centrifuge with a centrifuge, take the supernatant, and load the pretreated 732 cation exchange resin column (723 Wet packing of cation exchange resin to form a 40*300mm column bed, and then pretreatment), TCL de...

Embodiment 2

[0061] 1. Extraction: Weigh 10Kg of raw material powder into a 100-liter multi-functional extractor, add 65 liters of methanol, heat reflux at 65°C for 2 hours, filter, and collect the filtrate; add 65 liters of methanol at 65°C in a 100-liter multi-functional Heat reflux extraction in the extraction tank for 2 hours, filter, and collect the filtrate; add 65 liters of methanol at 65°C, heat reflux extraction in a 100 liter multifunctional extraction tank for 2 hours, filter, and collect the filtrate; combine the 3 extracts. Concentrate under reduced pressure at 40°C-60°C to no methanol in a 100-liter concentration tank to obtain Hudixiao extract.

[0062] 2. Separation: Weigh a certain amount of Hudixiao extract, dissolve it with 150 times the volume of 2% acetic acid aqueous solution, stir well, remove oily foam, centrifuge with a centrifuge, take the supernatant, and load the pretreated 732 cation Exchange resin column, TCL detects the end point of sample loading, after the ...

Embodiment 3

[0066] 1. Extraction: Weigh 200Kg of raw material powder into a 2000-liter extraction tank, add 1300 liters of methanol, heat reflux at 65°C for 2 hours, extract 3 times, and combine the 3 times of extracts. Concentrate under reduced pressure at 40°C-60°C to no methanol in a 500-liter concentration tank to obtain Hudixiao extract.

[0067] 2. Separation: Weigh a certain amount of Hudixiao extract, dissolve it with about 150 times the volume of 2% acetic acid aqueous solution, stir well, remove oily foam, centrifuge with a centrifuge, take the supernatant, and load the pretreated 732 Cation exchange resin column, TCL detects the end point of sample loading, after the resin absorbs alkaloids to saturation, rinse with 2BV of deionized water first, then alkalinize the resin bed with 1BV of 2% NaOH, and then elute the target with acetone (TCL detection Elution end point), concentrate the acetone eluent to about 2BV, and cool to room temperature. Dry with anhydrous sodium sulfate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com