Method for preparing one-dimensional nanometer materials by using polyelectrolyte to adjust and control 1-pyrene formaldehyde

A technology of polyelectrolyte and nanomaterials, which is applied in the field of preparing one-dimensional nanomaterials by using polyelectrolytes, can solve the problems of time-consuming and energy-consuming design, limited popularization and application, and long preparation process, etc., and achieves strong anti-fluorescence quenching performance, Wide range of material sources and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Dissolve polyallylamine (PAH) in methanol to make a 40mg / mL solution.

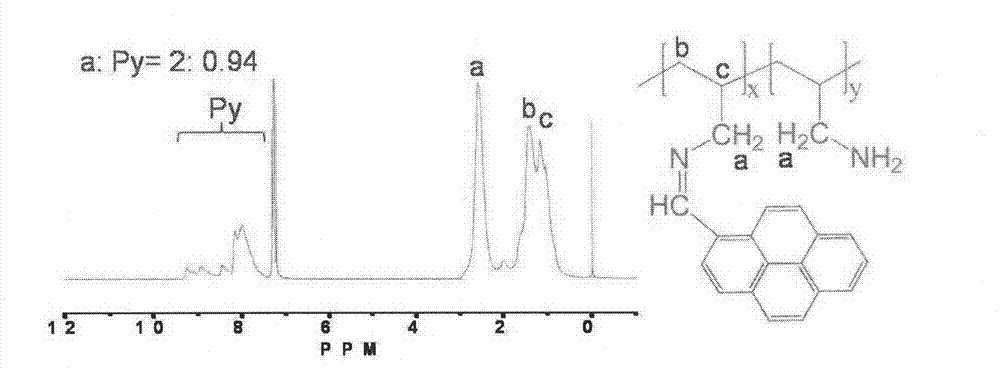

[0028] 2) 5 mL of the PAH solution in step 1) was mixed with 5 mL of 1-pyrene formaldehyde (Py-CHO) methanol solution with a concentration of 20 mg / mL, and stirred for 30 minutes. The reaction solution was poured into 400 mL of acetone, and the resulting precipitate was collected and redissolved in methanol. After repeated precipitation of the product twice, the product was dried in vacuo at 40 °C to obtain 1-pyrenecarbaldehyde-modified PAH (PAH-Py). The degree of substitution of Py-CHO relative to PAH unit chains in the obtained PAH-Py is 9.4%. The hydrogen nuclear magnetic resonance spectrum of PAH-Py is shown in figure 1 .

[0029] 3) The PAH-Py obtained in step 2) was dissolved in methanol to prepare a 10 mg / mL solution.

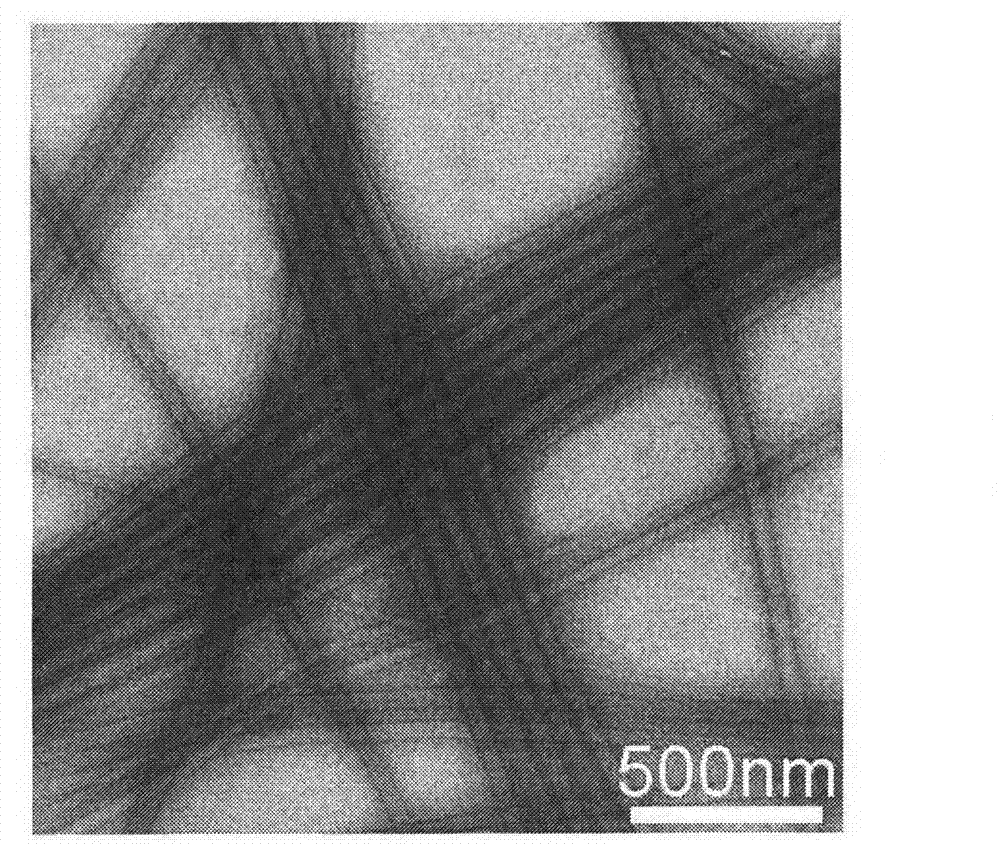

[0030] 4) Mix 10 mL of the above solution with 90 mL of 1 mol / L hydrochloric acid solution, and shake the mixed solution for 5 days to obtain one-dimensional nanotubes ...

Embodiment 2

[0032] 1) Dissolve PAH in methanol to prepare a 20mg / mL solution.

[0033] 2) 5 mL of the PAH solution in step 1) was mixed with 5 mL of a methanol solution of Py-CHO with a concentration of 10 mg / mL, and stirred for 30 minutes. The reaction solution was poured into 400 mL of tetrahydrofuran, and the resulting precipitate was collected and redissolved in methanol. After repeating the precipitation of the product twice, the product was dried in vacuo at 40 °C. 1-Pyrenecarbaldehyde-modified PAH (PAH-Py) was obtained, and the degree of substitution of Py-CHO relative to PAH unit chains in the obtained PAH-Py was 12.2%.

[0034] 3) Dissolve step 2) PAH-Py in methanol to prepare a 5 mg / mL solution.

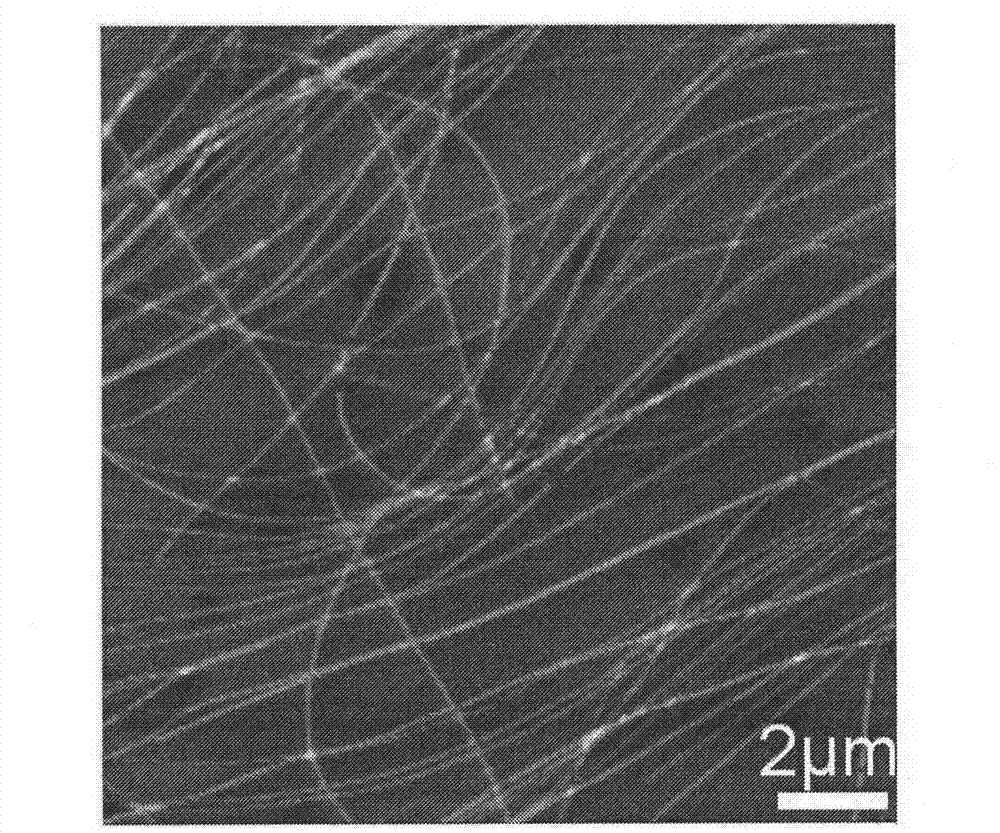

[0035] 4) Mix 10 mL of the above solution with 90 mL of 3 mol / L hydrochloric acid solution, shake the mixed solution slightly for 4 days, and obtain one-dimensional nanotubes formed by Py-CHO through π-π stacking interaction. The atomic force microscope photo of the prepared one-dim...

Embodiment 3

[0037] 1) Dissolve PAH in ethanol to prepare a 10mg / mL solution.

[0038] 2) 5 mL of the PAH solution in step 1) was mixed with 5 mL of a Py-CHO ethanol solution with a concentration of 4 mg / mL, and stirred for 30 minutes. The reaction solution was poured into 400 mL of acetone, and the resulting precipitate was collected and redissolved in ethanol. After repeating the precipitation of the product twice, the product was dried in vacuo at 40 °C. 1-Pyrenecarbaldehyde-modified PAH (PAH-Py) was obtained, and the degree of substitution of Py-CHO relative to PAH unit chains in the obtained PAH-Py was 7.9%.

[0039] 3) Dissolving the PAH-Py in step 2) in ethanol to prepare a 20 mg / mL solution.

[0040] 4) Mix 10 mL of the above solution with 90 mL of 2 mol / L hydrochloric acid solution, shake the mixed solution slightly for 6 days, and obtain one-dimensional nanotubes formed by Py-CHO through π-π stacking interaction. The laser confocal microscope photos of the prepared one-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com