Method for manufacturing high-purity metal wire

A manufacturing method and metal wire technology are applied in the field of directly using electrolytic metal plates to prepare high-purity metal wires, which can solve the problems of long production cycle, high cost and difficulty of copper wires, shorten the production cycle, eliminate pollution problems, and avoid The effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

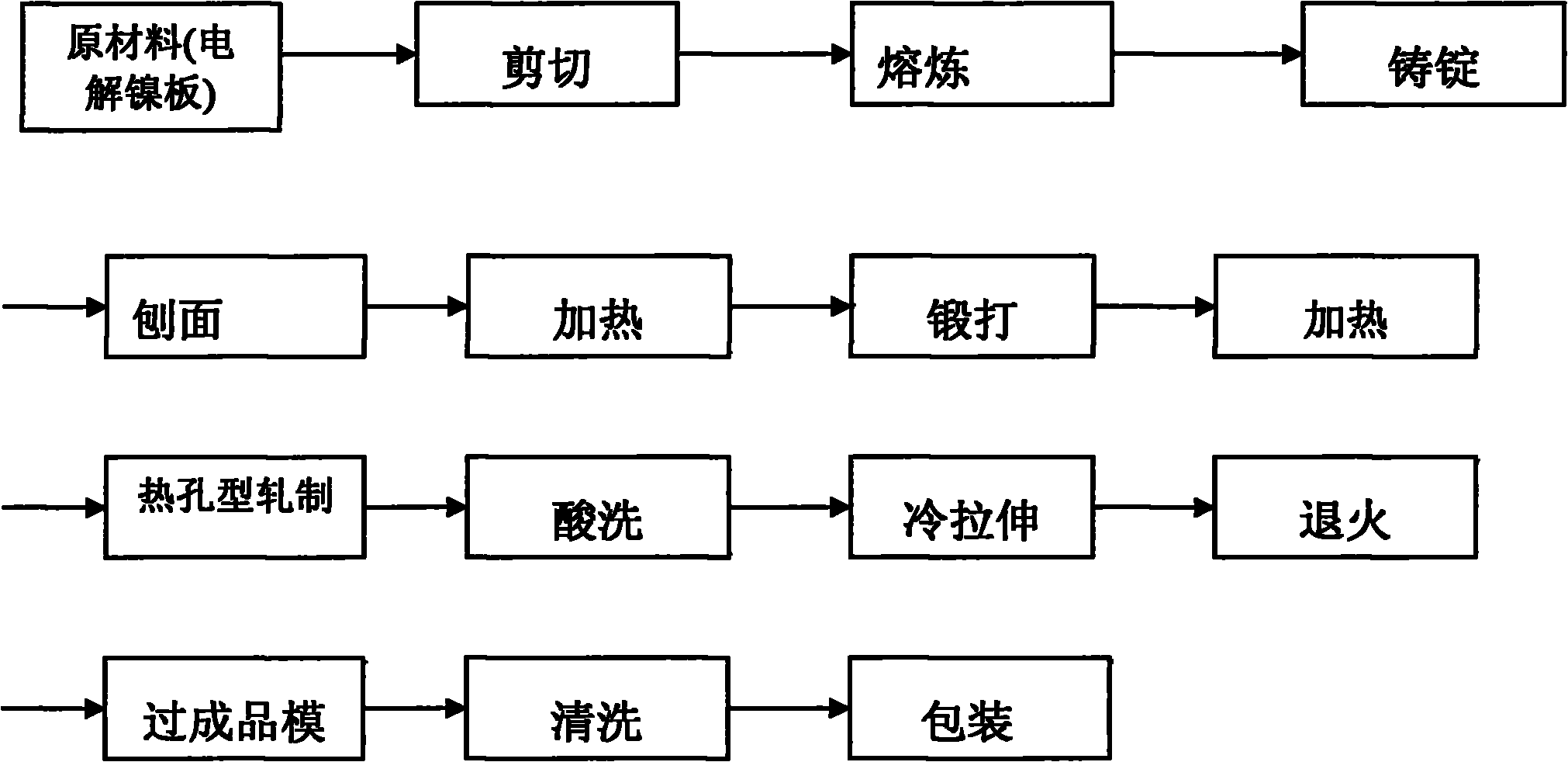

[0040] Embodiment 1, as figure 2 As shown, this embodiment takes the preparation of high-purity nickel wire as an example to describe the present invention in detail. This embodiment includes the following steps:

[0041] S1. Firstly, the electrolytic nickel raw material plate is cut and pre-degassed to form a raw nickel strip, wherein the degassing treatment is dehydrogenation and desulfurization treatment.

[0042] In this embodiment, the high-purity electrolytic nickel raw material plate is cut into nickel strips first, and then subjected to dehydrogenation and desulfurization treatment; the electrolytic nickel raw material plate can also be subjected to dehydrogenation and desulfurization treatment first, and then divided into nickel strips.

[0043] Dehydrogenation and desulfurization treatment is: place the slit nickel strip or unslit electrolytic nickel raw material plate in a gas or diesel combustion box-type heating furnace, heat it to 300°C, and heat it at this tem...

Embodiment 2

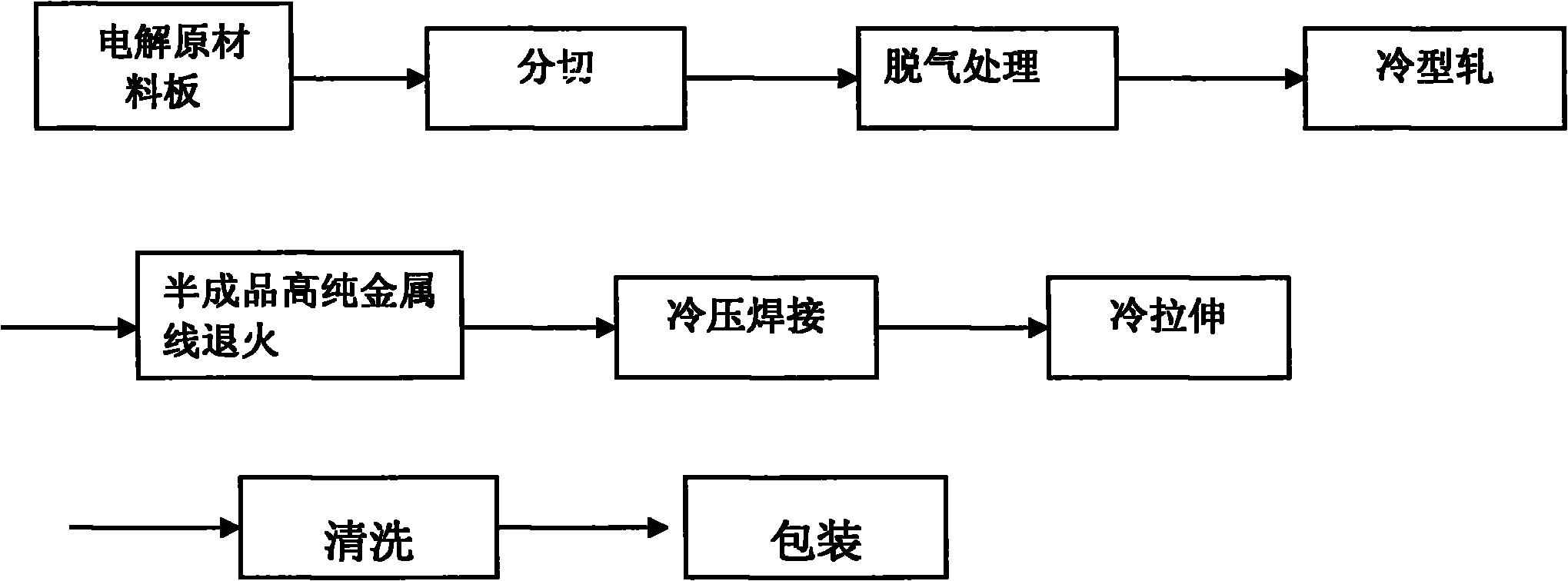

[0067] Embodiment 2, as image 3 As shown, a high-purity nickel wire was prepared. Steps S1-S5 of this embodiment are the same as those of Embodiment 1, and steps S1-S5 will not be described in detail here.

[0068] When the user needs non-soft high-purity metal wire for delivery, before the high-purity metal wire is drawn to the wire diameter of the finished high-purity metal wire, continuous annealing treatment before the finished product is carried out, and then the wire is drawn to the wire diameter of the finished high-purity metal wire size. Specifically, the continuous annealing treatment before the finished product is an annealing treatment by directly passing an electric current on the high-purity metal wire. , the larger the current is. After continuous annealing treatment before the finished product, it is passed through the finished product mold, that is, it is drawn to the required product high-purity metal wire diameter size by a single-mode or multi-mode wire...

Embodiment 3

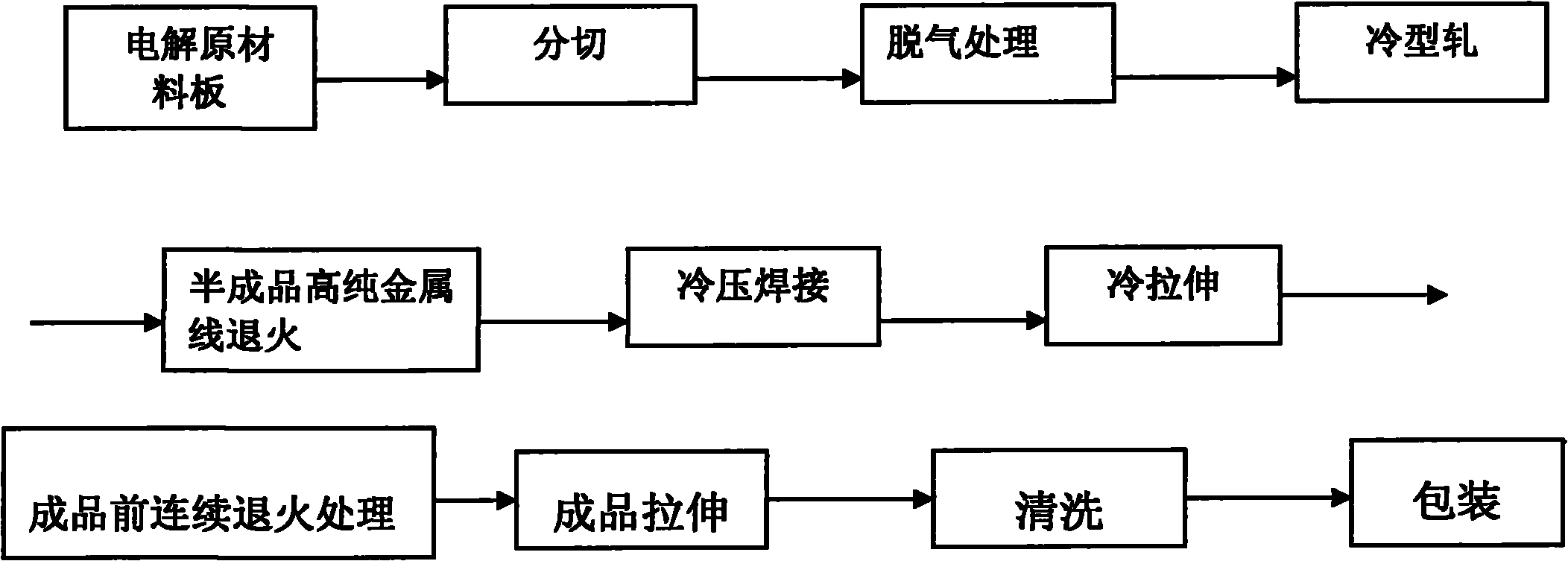

[0074] Example 3, such as image 3 As shown, a high-purity nickel wire was prepared. In this embodiment, the annealing treatment before the post-finished product in the step S5 adopts continuous annealing treatment in a tube furnace. All the other steps are with embodiment 1.

[0075] The pre-finished product annealing treatment in this embodiment selects continuous annealing treatment in a tube furnace under a reducing atmosphere of ammonia decomposition gas, wherein the annealing temperature is 650°C-850°C, and the annealing speed is 2m / min-6m / min. The larger the diameter of the high-purity metal wire, the slower the annealing speed and / or the higher the annealing temperature. The specific annealing parameters of the tube furnace are shown in Table 7.

[0076] Table 7

[0077] diameter (mm)

[0078] When the diameter is less than 1mm, an annealing speed of 5m / min at 650°C can also be selected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com