Process method for recycling precious metal from electroplating wastewater

A technology of electroplating wastewater and process methods, applied in the field of recycling precious metals, can solve problems such as declining competitiveness of enterprises, high treatment costs, and polluting the environment, and achieve the effects of low water treatment costs, reduced environmental pollution, and convenient system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

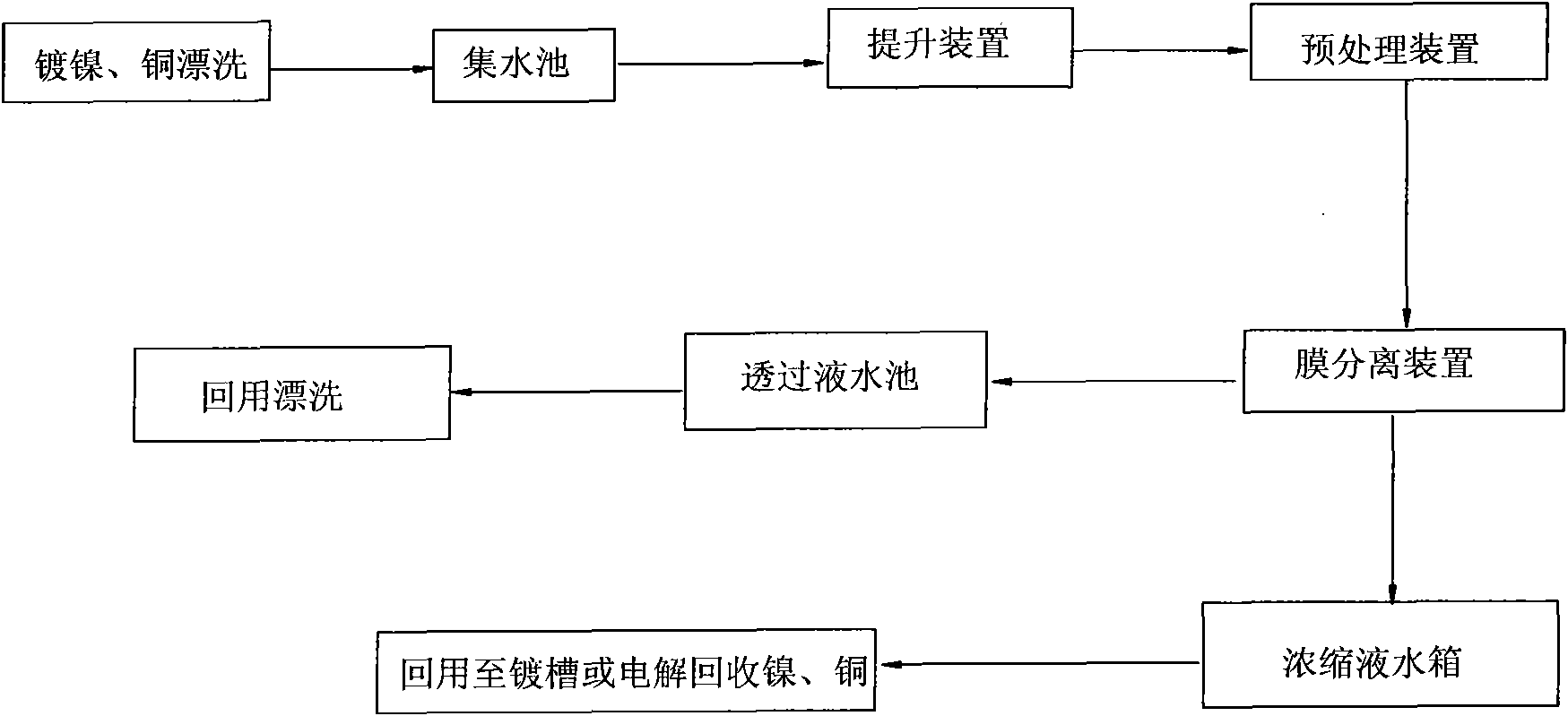

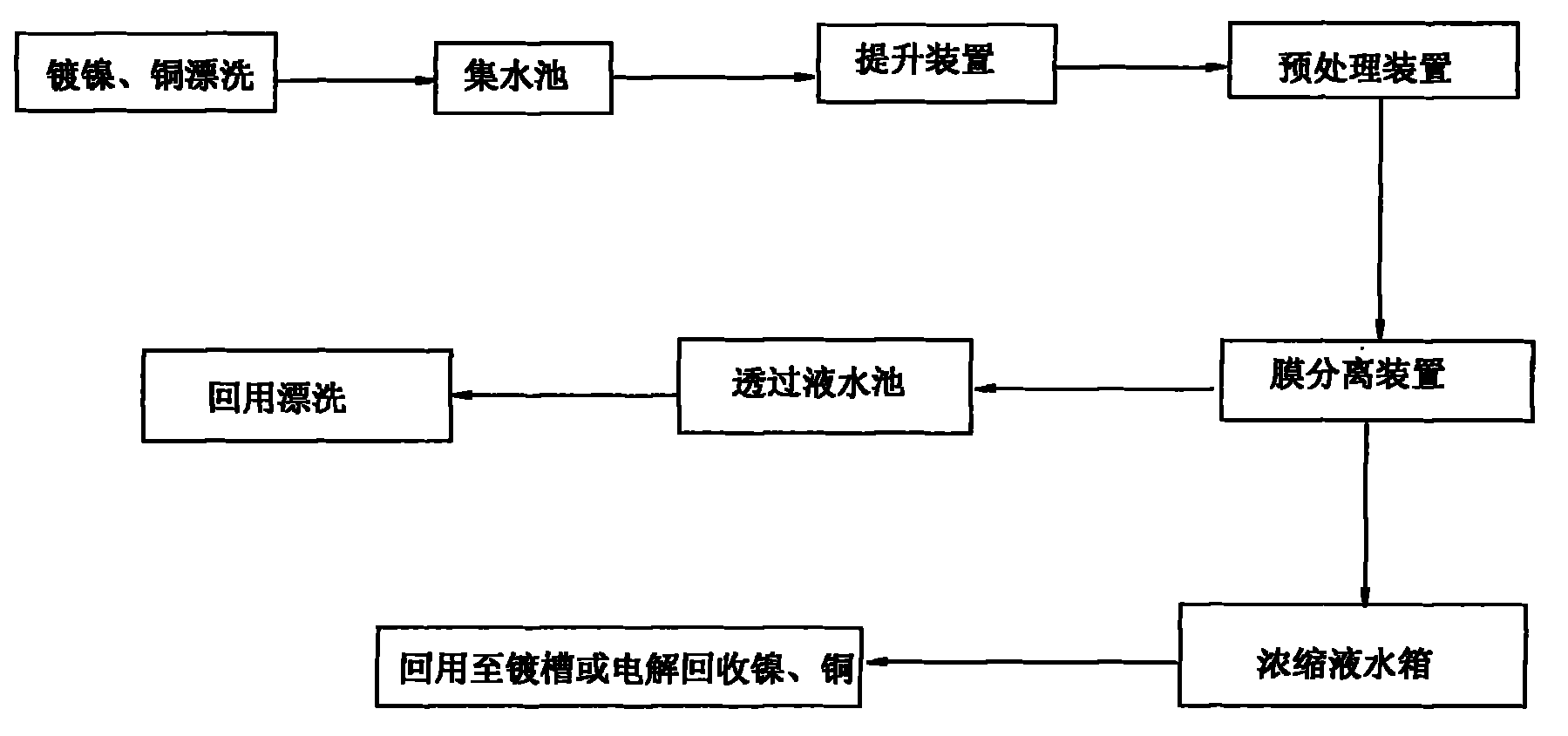

[0015] Depend on figure 1 and 2 As shown, a process for recovering precious metals from electroplating wastewater according to the present invention involves putting the wastewater into a sump, and then using a lifting device to lift the wastewater to the next step, which also includes the following steps:

[0016] Electroplating wastewater pretreatment step: the electroplating wastewater is passed through a quartz sand filter, an activated carbon filter and a filter element filter in order to remove impurities, and the filtrate enters the next step;

[0017] Membrane concentration step: Put the filtrate obtained in the above step into the membrane bioreactor for step-by-step concentration and separation, collect the permeate into the permeate pool, and use it as rinsing water in the electroplating line; the concentrate enters the concentrate tank, and Recycle to the plating tank or electrolytically recover nickel.

[0018] Each filter membrane in the above-mentioned membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com