Real-time detection and control method of instability of flame in industrial furnace

A real-time detection and stability technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of lack, poor timeliness, and phase space prior information without chaotic time series, and achieve high real-time performance and fast response Fast, simple operation and control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

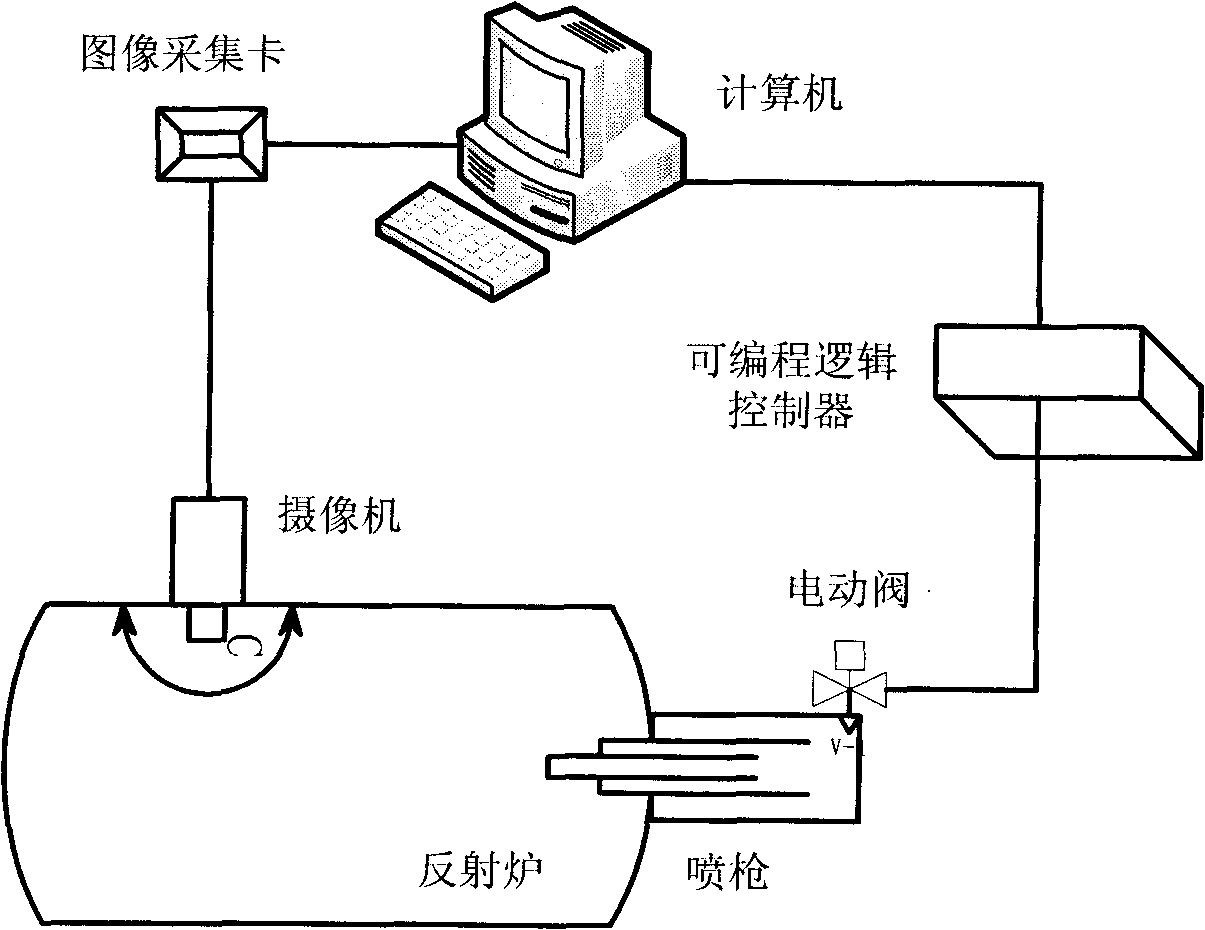

[0022] A reverberatory furnace for copper refining in a smelter, according to the attached figure 1 The way to arrange detection and control system, real-time monitoring of the combustion process. The system includes: a camera for taking images of the flame tip; a computer for processing the digital information of the captured flame pictures to determine whether to issue commands to the programmable logic controller (ie, PLC, Programmable Logic Controller) to control the adjustment of the regulator supply oil pressure and oil quantity; and an oil pressure control and oil quantity supply device for supplying oil quantity into the fuel device, the oil pressure control and oil quantity supply device is triggered by the output of the computer.

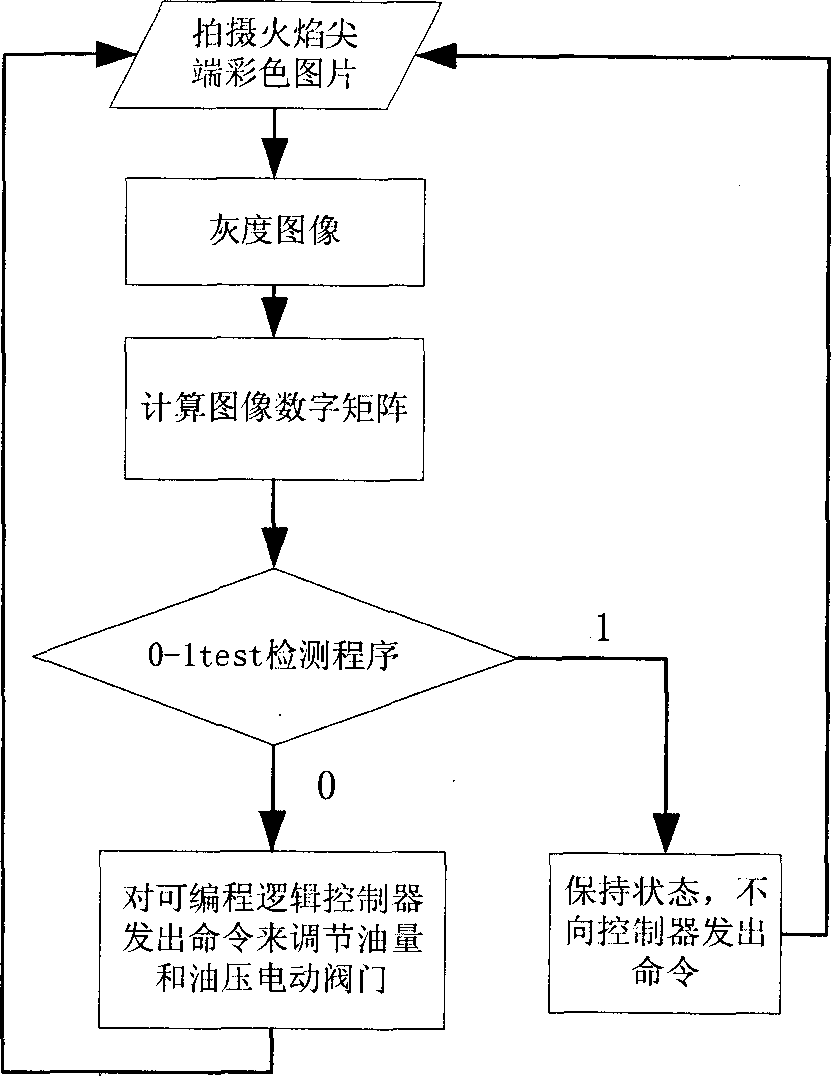

[0023] Through the camera and the image acquisition card, collect the real-time pattern of the burning flame at the time t1 (obtained by the color CCD camera and the image acquisition card), and then use the computer image processing progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com