Method for synthesizing halogen aromatic amines by high-selectivity liquid phase hydrogenation under the condition of no solvent

A technology of liquid-phase hydrogenation of halogenated aromatic amines, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino compounds, etc., can solve problems such as difficulties in the recovery of precious metals, influence on product purification, and speed up the reaction rate. Catalyst active center, the effect of inhibiting dehalogenation is obvious, and the effect of reducing the probability of reaction

Inactive Publication Date: 2010-08-25

ZHEJIANG UNIV OF TECH

View PDF12 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the existing catalytic hydrogenation technology, there are still problems in the preparation process of modified catalysts, the difficulty in recovering precious metals, and the addition of dehalogenation inhibitors to affect product purification.

And the dehalogenation rate is generally higher than 0.2%, and it is impossible to synthesize ultra-high-quality halogenated aromatic amines that meet the requirement of a single impurity content of less than 0.1% in pharmaceutical intermediates in one step

In addition, the hydrogenation reduction process usually requires the addition of a large amount of volatile organic solvent (the ratio of raw material to solvent is about 1:1.2-2 (Kg / L)) to dissolve the raw material or product, and increase the amount of reactants, hydrogen and catalyst. The contact probability between phases can enhance the mass transfer and heat transfer effect and speed up the reaction rate; however, the use of solvent will increase the post-treatment process such as product separation and solvent recovery, which will lead to increased investment cost, increased energy consumption, reduced safety factor, A series of problems such as the deterioration of the working environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Login to View More

Abstract

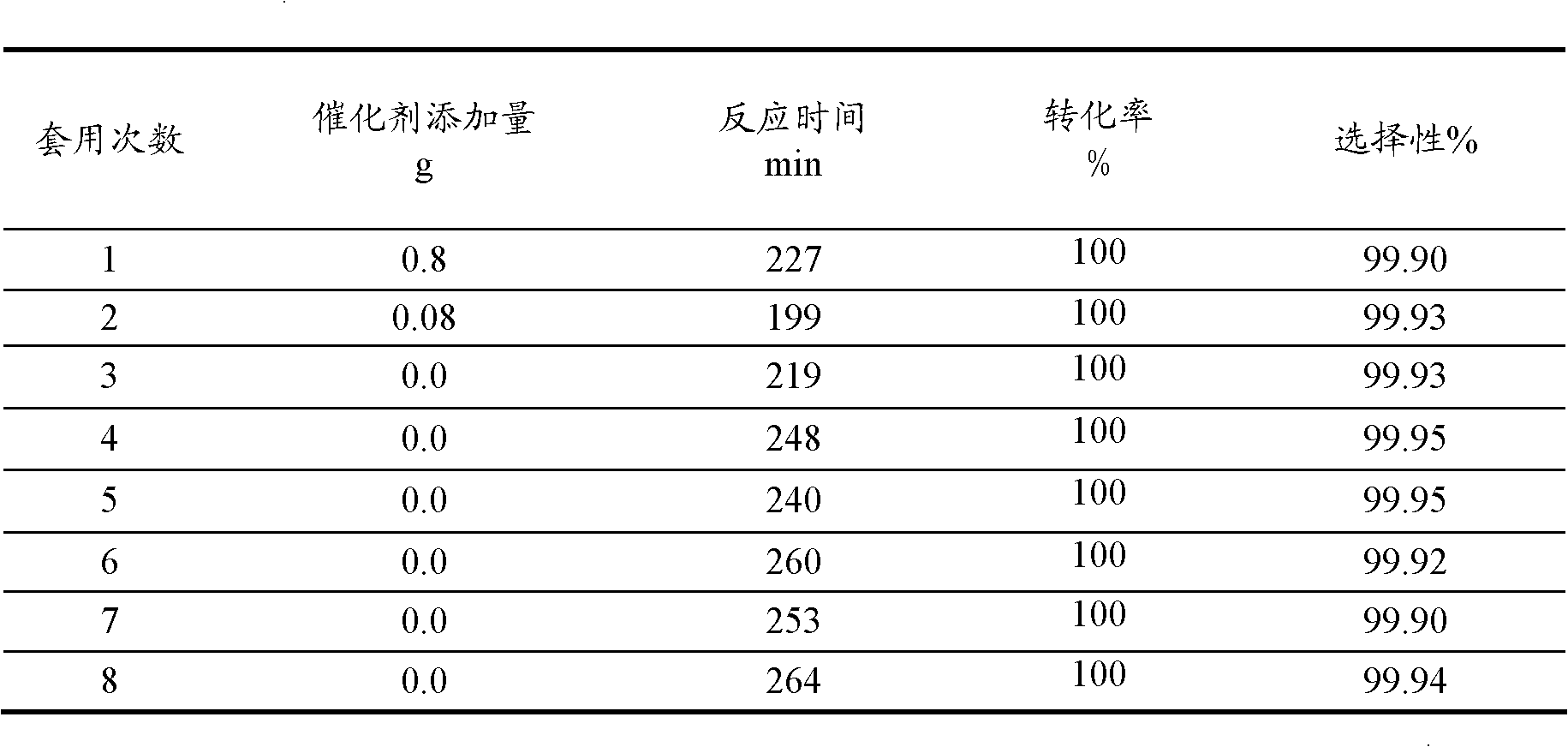

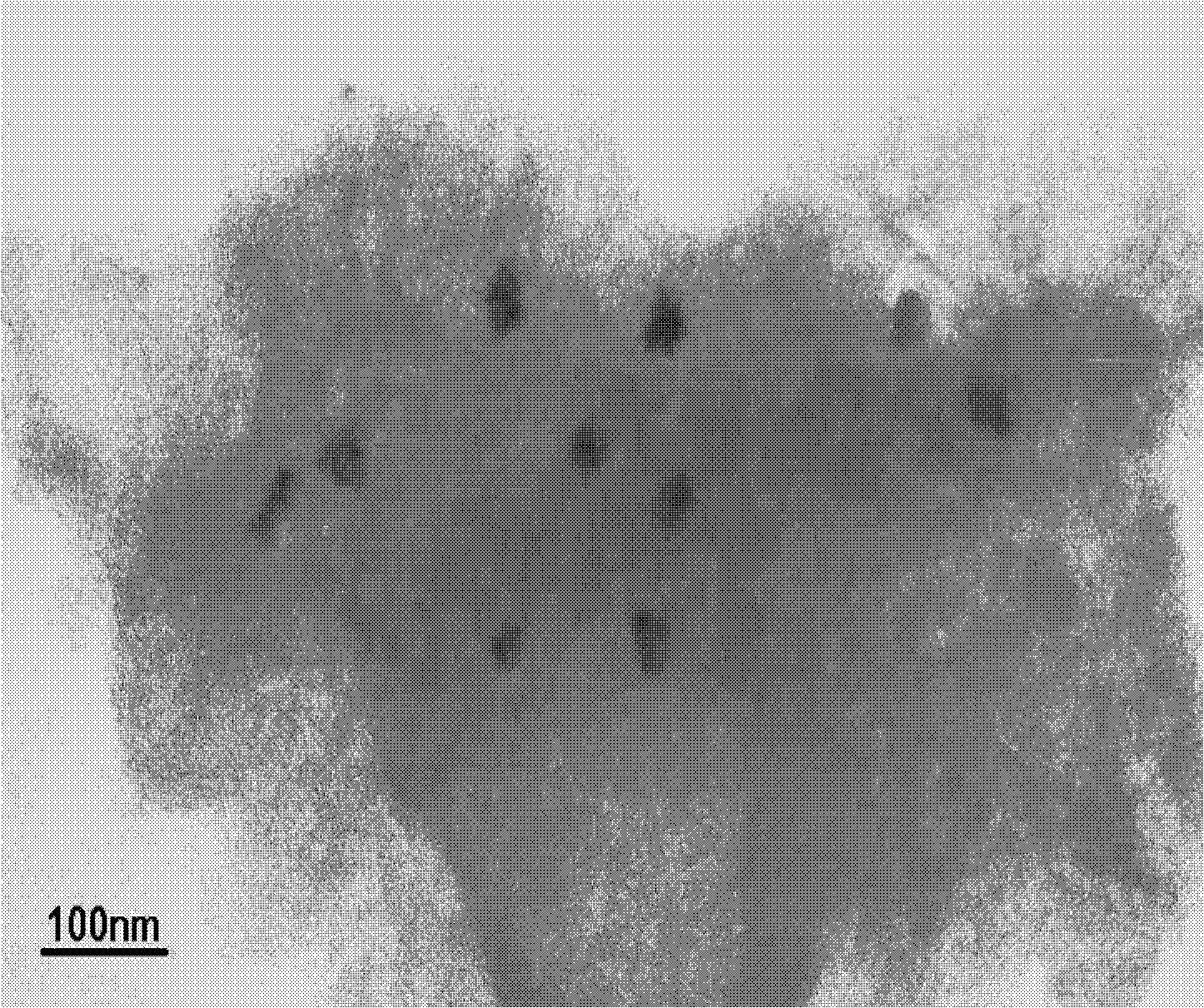

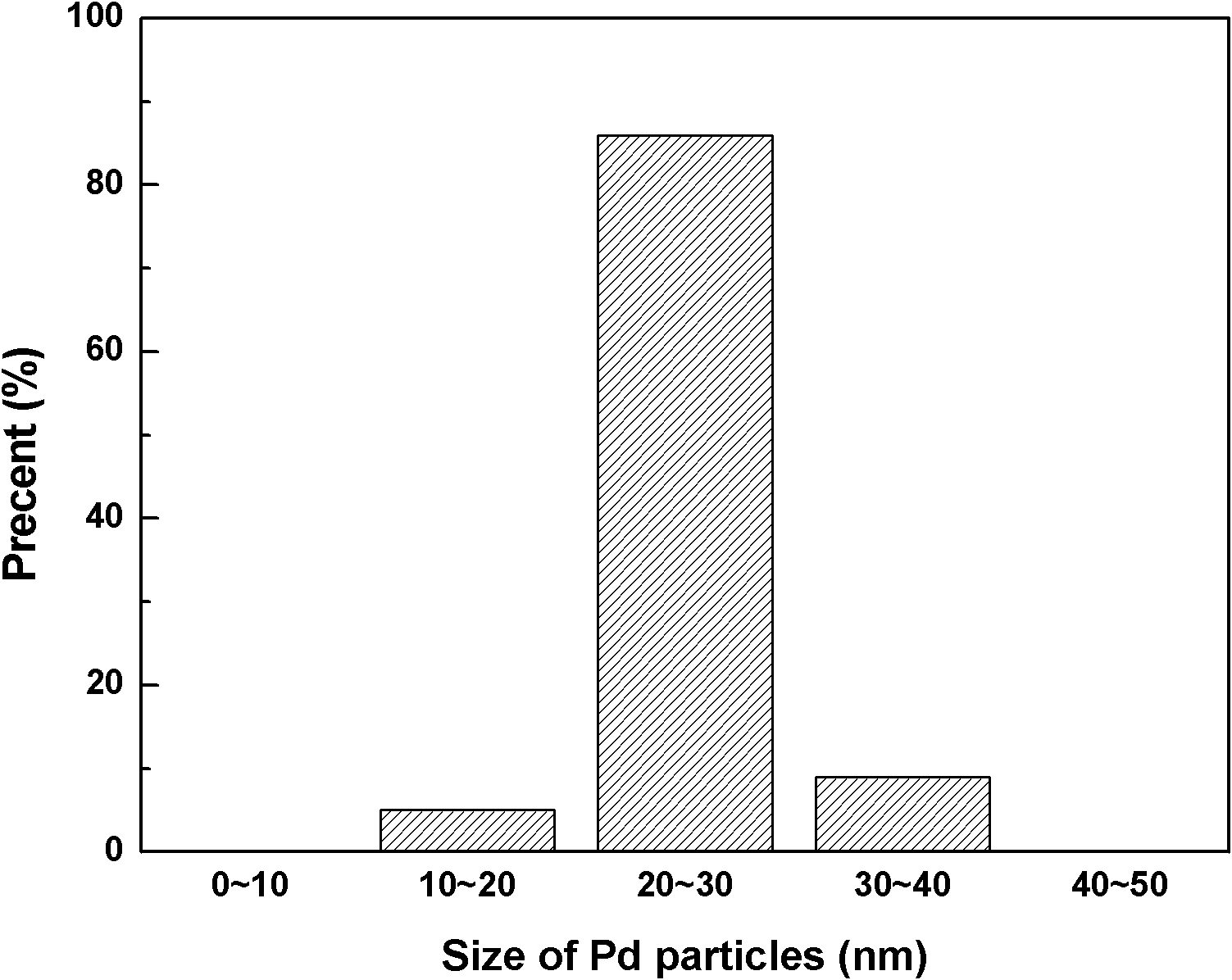

The invention discloses a method for synthesizing halogen aromatic amines by halogen aromatic nitro compounds through liquid phase hydrogenation, which is characterized in that: the reaction for synthesizing the halogen aromatic amines by the halogen aromatic nitro compounds through liquid phase hydrogenation is carried out in the presence of a Pd / C catalyst under the condition of no solvent; and the method for preparing the Pd / C catalyst comprises the following steps of: performing impregnation pretreatment on active carbon by using aqueous solution of potassium halide, and filtering and washing until the filter liquor does not contain halide ions; preparing the pretreated active carbon into slurry by using de-ionized water, adding aqueous solution of HaPdCl4 dropwise for impregnation treatment, adjusting the pH value to alkali, and filtering and washing until the filter liquor is neutral; and preparing the obtained filter cakes into slurry by using de-ionized water, reducing in aqueous solution of reducing agent by a wet method, and filtering and washing until the filter liquor is neutral to obtain the Pd / C catalyst. The catalyst is adopted to prepare the halogen aromatic amines under the condition of no solvent, the selectivity is over 99.9 percent, the product quality meets the medical requirements, the production process is simplified, the production cost and energy consumption are reduced, the production efficiency is improved, and adverse factors such as solvent and product steam severely harming human bodies and polluting environment are improved.

Description

(1) Technical field The invention relates to a method for synthesizing halogenated aromatic amines by liquid-phase catalytic hydrogenation of halogenated aromatic nitro compounds. (2) Background technology Halogenated anilines are important basic chemical raw materials and organic chemical intermediates, and are widely used in the synthesis of fine chemicals such as pharmaceuticals, pesticides, and dyes. Its production methods are mainly prepared by the reduction of corresponding halogenated aromatic nitro compounds, including chemical reduction methods (iron powder reduction method, alkali sulfide reduction method and hydrazine hydrate reduction method, etc.), electrolytic reduction method and catalytic hydrogenation reduction method. The chemical reduction method has the advantages of simple process route, simple operation, small investment, etc., and is relatively mature in technology. However, this method generally has defects such as large environmental pollution, low pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C209/36C07C211/52B01J23/44

Inventor 李小年卢春山吕井辉袁俊峰马磊张群峰石玉梅许孝良

Owner ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com