High-protein straw feed and preparation method thereof

A straw feed and high-protein technology, applied in animal feed, animal feed, application, etc., can solve the problems of low raw grain replacement rate, low crude protein content, and many components, so as to increase protein content, optimize protein structure, improve The effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing high-protein straw feed, comprising the following steps:

[0021] 1. Screen, isolate, purify, rejuvenate and cultivate Bacillus stearothermophilus, Nocardia, Lactobacillus acidophilus and Bacillus subtilis, respectively, and transplant the above-mentioned bacteria into industrial fermentation tanks for fermentation. The fermentation conditions are that the medium composition of Bacillus stearothermophilus is: 0.05% sodium chloride, 0.05% dipotassium hydrogen phosphate, 0.05% magnesium sulfate, 0.05% calcium carbonate, 0.1% Tween-80, 5% brown sugar, 0.5% yeast extract, 0.5% peptone, culture time 22 hours, culture temperature 62 ℃; Nocardia, acidophilus, Bacillus subtilis medium composition: 0.05% sodium chloride, 0.05% dihydrogen phosphate Potassium, 0.05% magnesium sulfate, 0.05% calcium carbonate, 0.1% Tween-80, 5% brown sugar, 0.5% yeast extract, 0.5% peptone, the culture time is about 22 hours, the culture temperature is 35 ℃, the inoculation d...

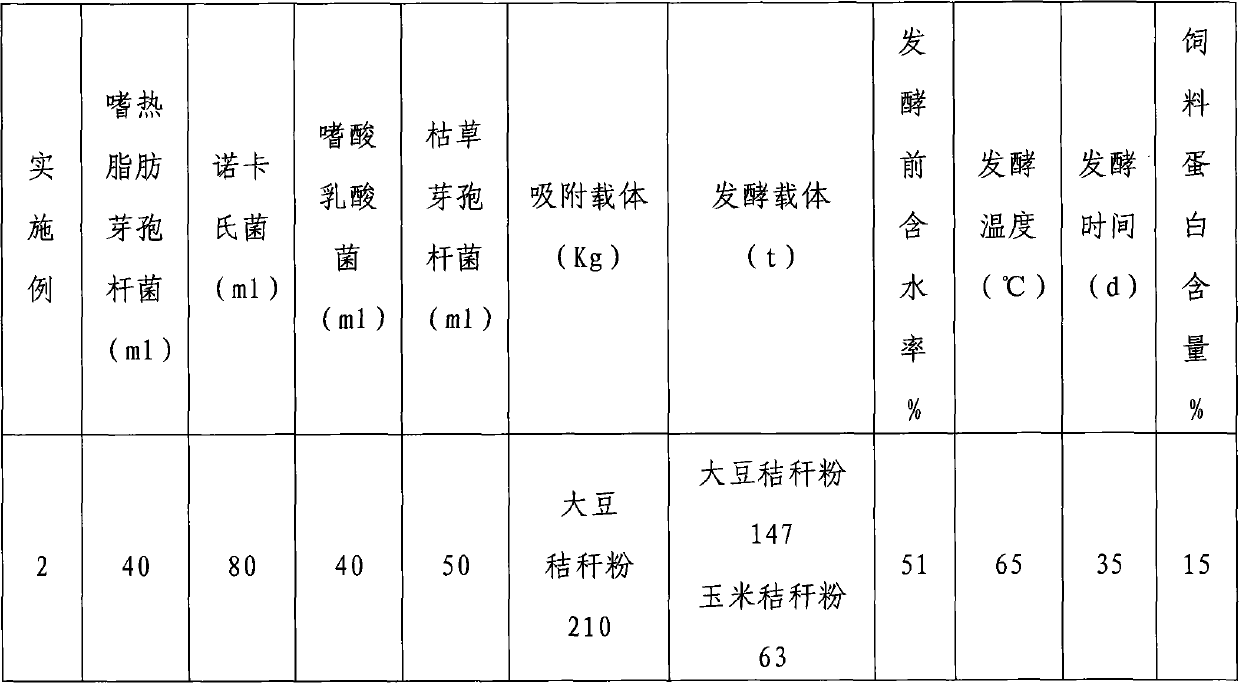

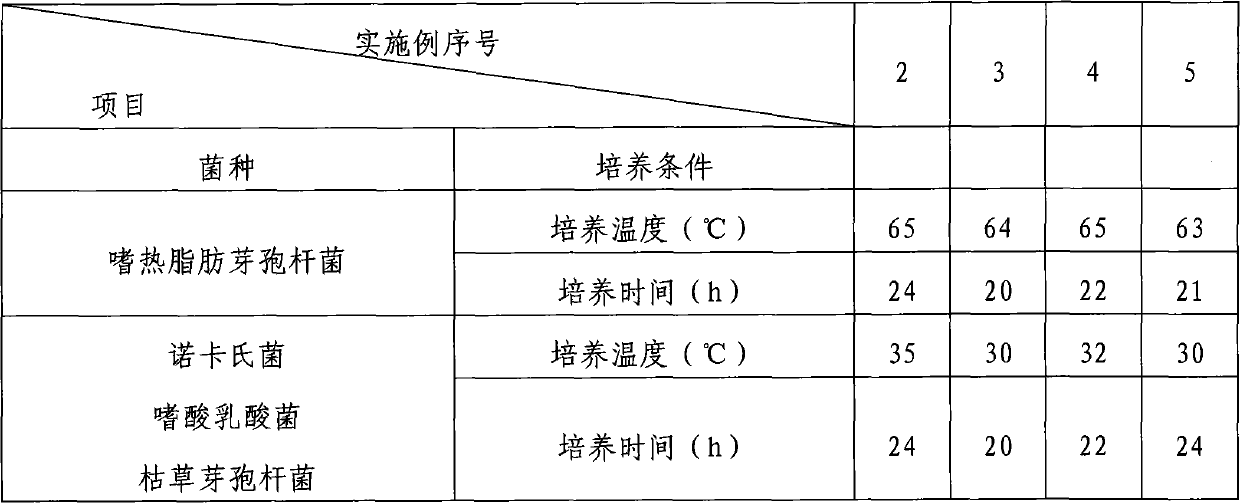

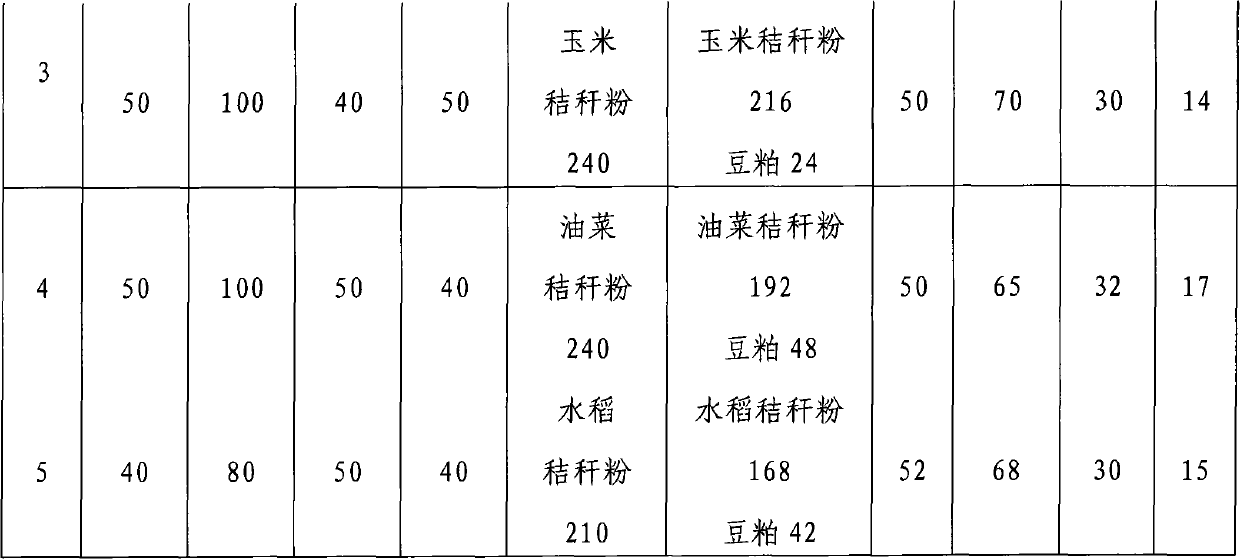

Embodiment 2 5

[0027] The culture condition of table 2 embodiment two to five strains

[0028]

[0029] In Embodiment 2 to Embodiment 4, except for the data involved in Tables 1 and 2, other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com