Laser welding method of rhenium alloy thin sheet

A technology of laser welding and rhenium alloy, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., to achieve the effect of preventing oxidation, easy operation and optimizing welding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

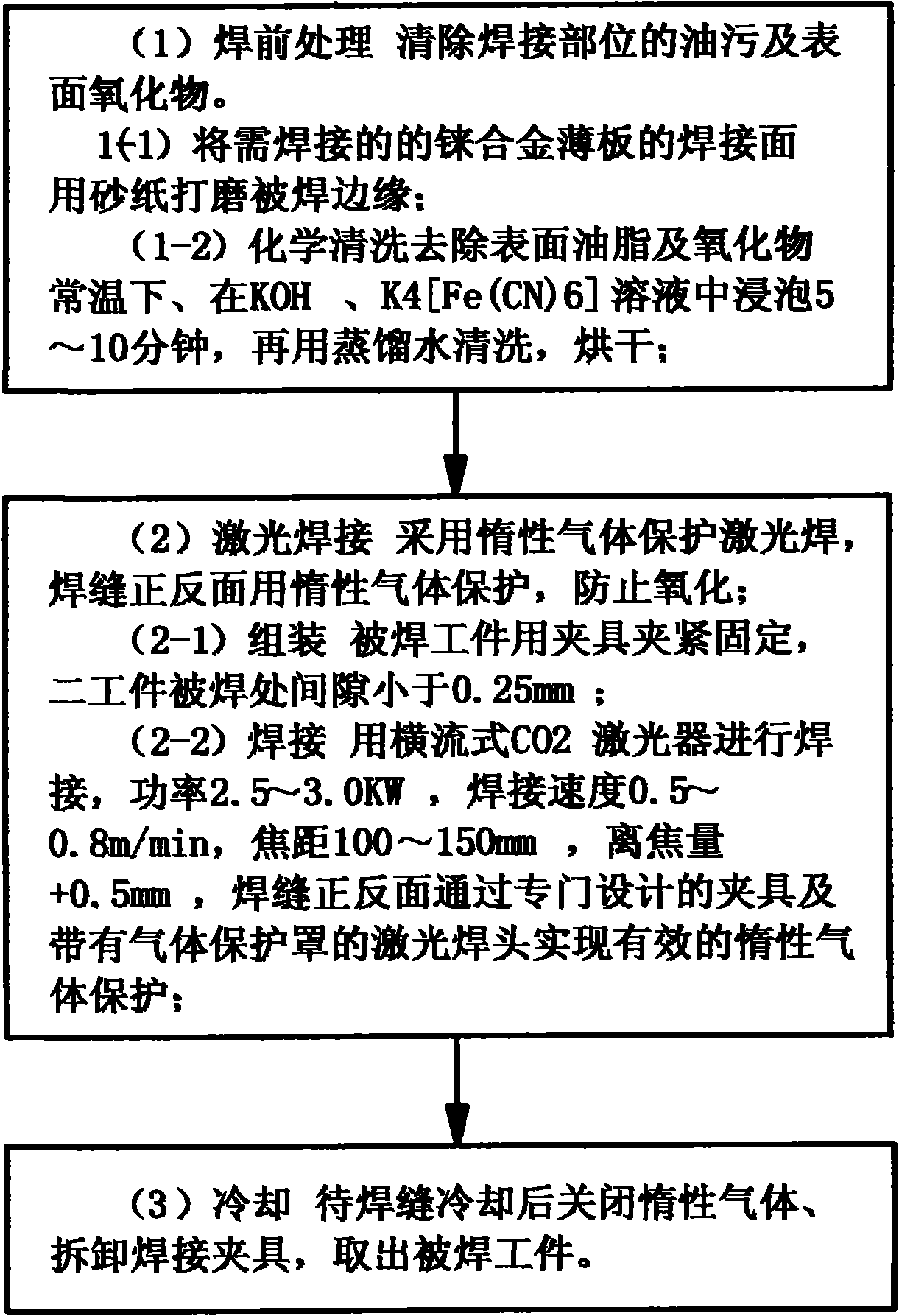

[0025] figure 1 Shown is the flowchart of the rhenium alloy sheet laser welding method provided by the present invention, which includes the following steps:

[0026] (1) Pre-welding treatment Remove the oil stains and surface oxides on the welding parts.

[0027] (1-1) grinding the welded edge of the rhenium alloy thin plate to be welded with sandpaper;

[0028] (1-2) Chemical cleaning to remove surface grease and oxides at room temperature, in KOH, K 4 [Fe(CN) 6 ] solution for 5 to 10 minutes, then washed with distilled water and dried;

[0029] (2) Laser welding Inert gas shielded laser welding is used, and the front and back of the weld are protected by inert gas to prevent oxidation.

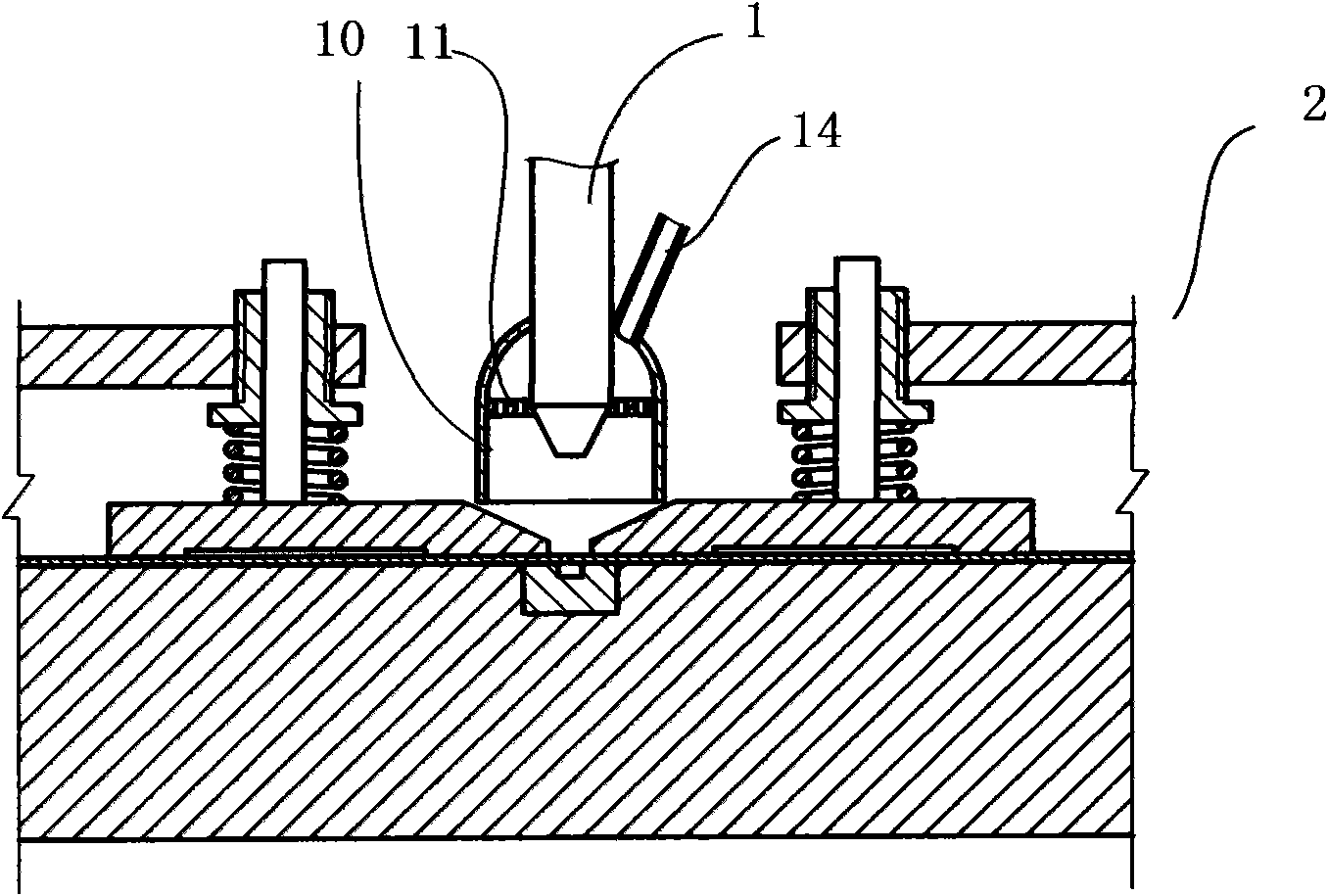

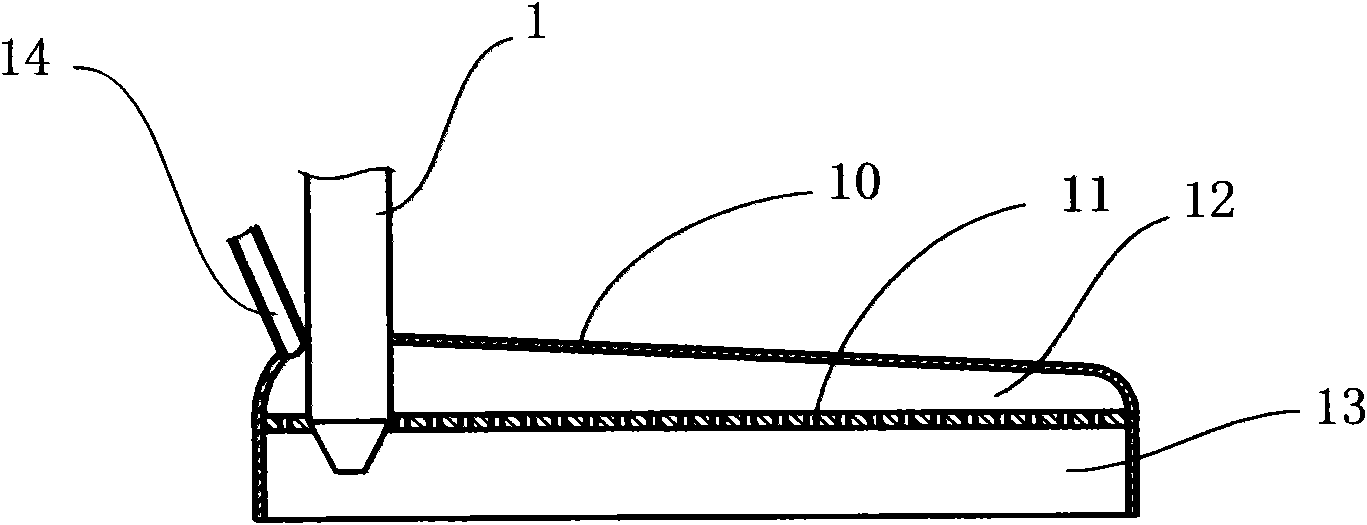

[0030] (2-1) Assembly The workpiece 3 to be welded is clamped and fixed by the fixture 2 (such as figure 2 As shown), the gap between the two workpieces to be welded is less than 0.25mm;

[0031] (2-2) Cross-flow CO for welding 2 Laser welding, power 2.5 ~ 3.0KW, welding speed 0.5 ~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com