Method for manufacturing carbon microspheres by using waste macromolecules

A technology of carbon microspheres and polymers, which is applied in the field of making waste polymers into carbon microspheres, can solve the problems of relatively harsh reaction conditions, products containing a large amount of impurities, and difficult to be widely used, and achieve low cost, The effect of uniform product scale and controllable production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. Preparation of carbon spheres in supercritical carbon dioxide

[0020] Weigh 1.50g of polyester (PET) flakes and 12g of dry ice, place them in an autoclave with a capacity of 20ml, and seal; heat to 650°C at a heating rate of 10°C / min, keep warm for 3 hours, cool to room temperature, and turn on the high pressure After the remaining carbon dioxide is released, a black powdery solid product is obtained. The remaining organic matter in the product is washed away with absolute ethanol, filtered, and then the solid powder is dried in an oven at 60°C for 6 hours to obtain the product.

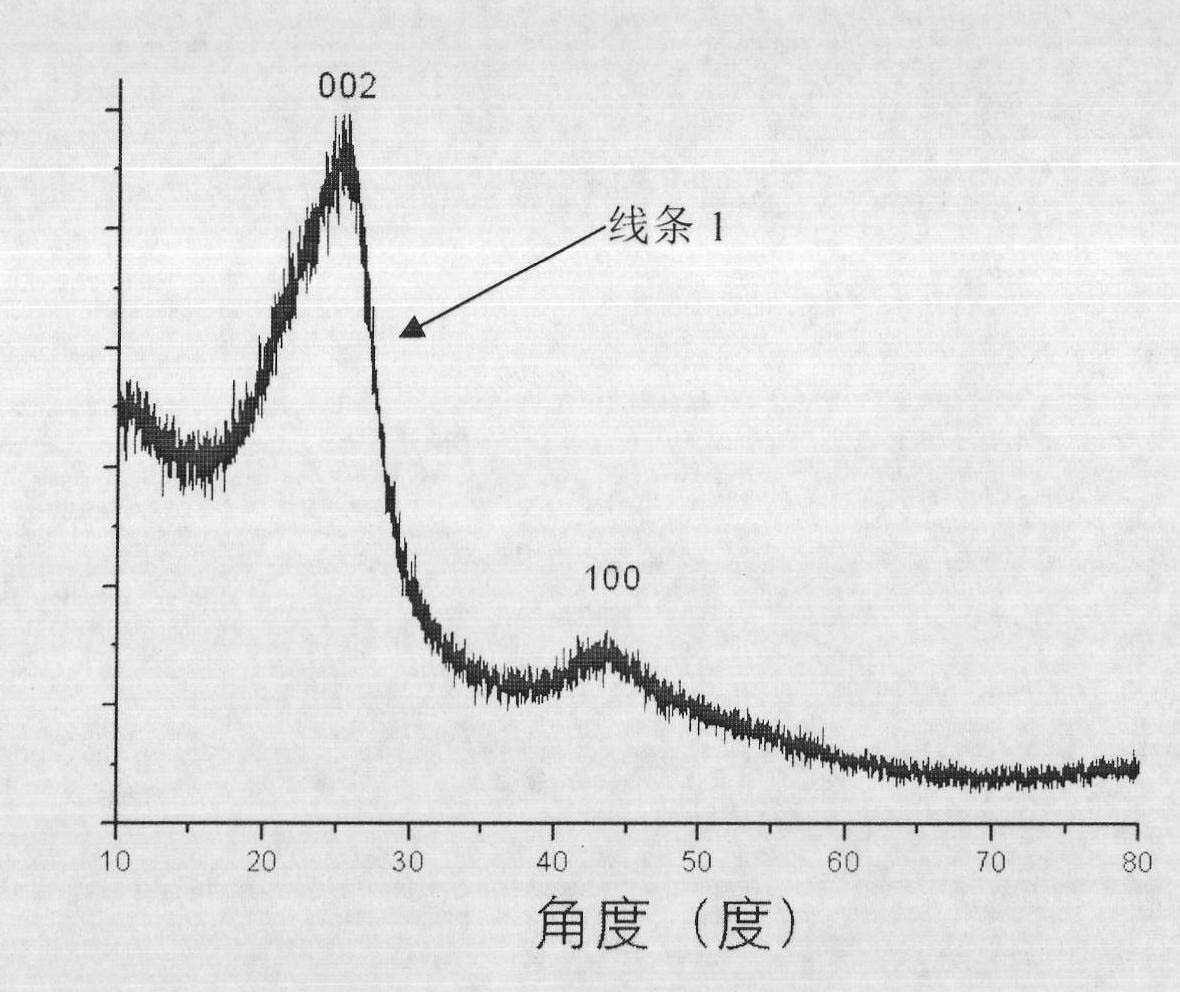

[0021] Product composition can be analyzed by X-ray diffraction OK, the X-ray diffraction analysis results are as follows figure 1 As shown in middle line 1: the peak positions of the two diffraction peaks of the product prepared by PET are at 25.3° and 43.6° respectively, corresponding to the (002) and (100) planes of graphite respectively, and the peak broadening at 25.3° is ob...

Embodiment 2

[0024] Embodiment 2. The impact of reaction conditions (temperature, time, etc.) on the product——taking PET as an example

[0025] Weigh several portions of each 1.50g polyester (PET) sheet and 12.0g dry ice, place each in an autoclave with a capacity of 20ml, seal it; heat it to 500°C, 600°C and 650°C respectively at a heating rate of 10°C / min. ℃, after 3 hours of heat preservation, cool to room temperature, open the autoclave, release the residual carbon dioxide, wash the obtained black powdery solid product with absolute ethanol to remove the remaining organic matter in the product, filter, and then the solid powder Dry in an oven at 60°C for 6 hours.

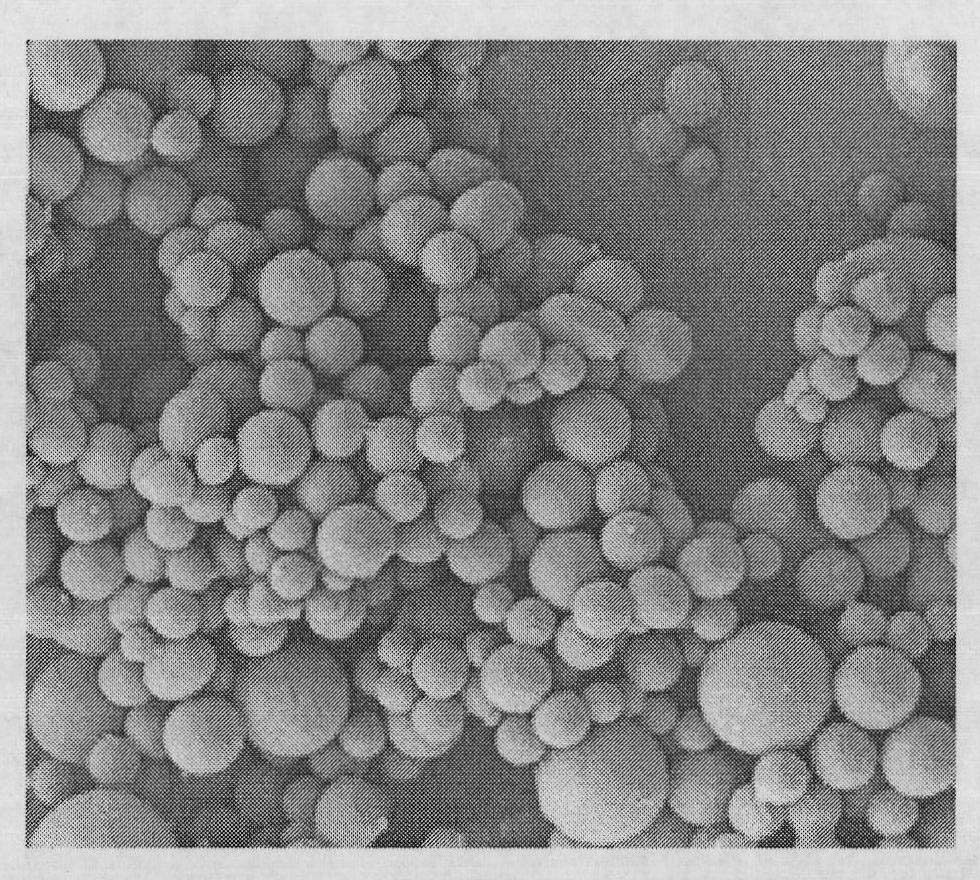

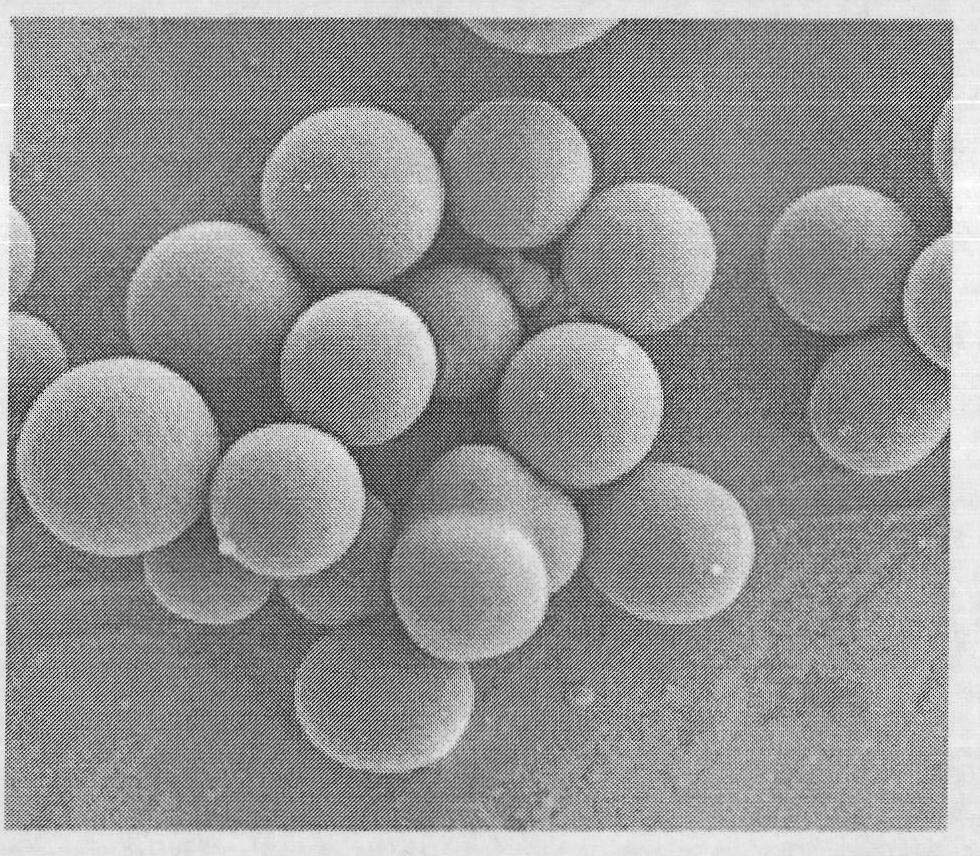

[0026] Field emission scanning electron microscopy showed that the products prepared above were all spherical, but the surface of the carbon microspheres obtained when the temperature was relatively low (500 ° C) or the reaction time was short (1 hour) was relatively rough. When the temperature rose to 600 The surface of ca...

Embodiment 3

[0028] Example 3. Preparation of layered carbon spheres by high-temperature annealing of carbon microspheres

[0029] Weigh 1 to 3 grams of carbon spheres prepared in Example 1, put them into a corundum crucible, place them in the center of a corundum tube furnace, add heat-insulating refractory bricks at both ends of the tube to keep warm, seal, and evacuate to 1% to 1000% Atmospheric pressure; heat up to 1500°C at a heating rate of 10°C / min, keep warm for 60 minutes, cool to room temperature, ventilate to balance the pressure, and turn on the tube furnace to obtain a light black powdery solid product.

[0030] X-ray diffraction (XRD) analysis shows that the (002) diffraction intensity of graphite in the product is obviously stronger, and the peak width shrinks, indicating that the degree of graphitization is significantly enhanced; The data are in contrast, indicating that the number of sp3 carbon hybridization defects in the product increases with the annealing reaction.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com