Method for preparing foamed ceramics based on nano-alumina

A technology of nano-alumina and foamed ceramics, which is applied in the field of foamed ceramics preparation, can solve the problems of high preparation cost, difficult to deal with halogen pollutants, difficult to light refractory bricks and ceramic fibers, etc., and achieves low cost, simple equipment and process. , the effect of easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take by weighing 500g, the commercially available 99.9% nano-alumina that particle size is 30nm, take by weighing 400g deionized water, take by weighing 15g purity and be 99.5% propionic acid solution, pour in the ball mill jar of 5L, add and material volume 1: 1 For agate balls, make two identical ball milling jars according to this method, put the ball milling jars into a ball mill and grind and stir for 6 hours to form a stable suspension of particles; take out the suspension in each jar, filter the ball milling medium and place them separately, one of the jars , weigh the weight of the suspension to be 896g, add 900g of octane with a purity of 98% to the suspension, and form a microemulsion with an "oil-in-water" structure after fully stirring; inject the microemulsion into an internal size of 250mm*250mm* In a 50mm square mold, the frame of the mold is made of grid-shaped stainless steel, the bottom of the mold and the surrounding area are sewn flat with gauze, and ...

Embodiment 2

[0025] Same method as in Example 1 for the stable suspension of particles, take out another tank of suspension in Example 1, weigh the suspension weight to be 898g, add 400g of octane with a purity of 98% to the suspension, and fully stir Finally form the microemulsion of " oil in water " structure; This microemulsion is injected in the mold identical with embodiment 1, the microemulsion in the mold box adopts air-drying to form foamy sample after 10 days; After drying, put the sample together with the mold Sinter in a sintering furnace at 800°C for 8 hours to obtain nano-alumina foam ceramics with a certain strength; after that, take out the nano-alumina foam ceramics with a certain strength from the stainless steel mold and put them in a high-temperature sintering furnace at 1350°C for sintering After 8 hours, a high-strength ceramic foam was obtained with a bulk density of 0.22g / cm 3 .

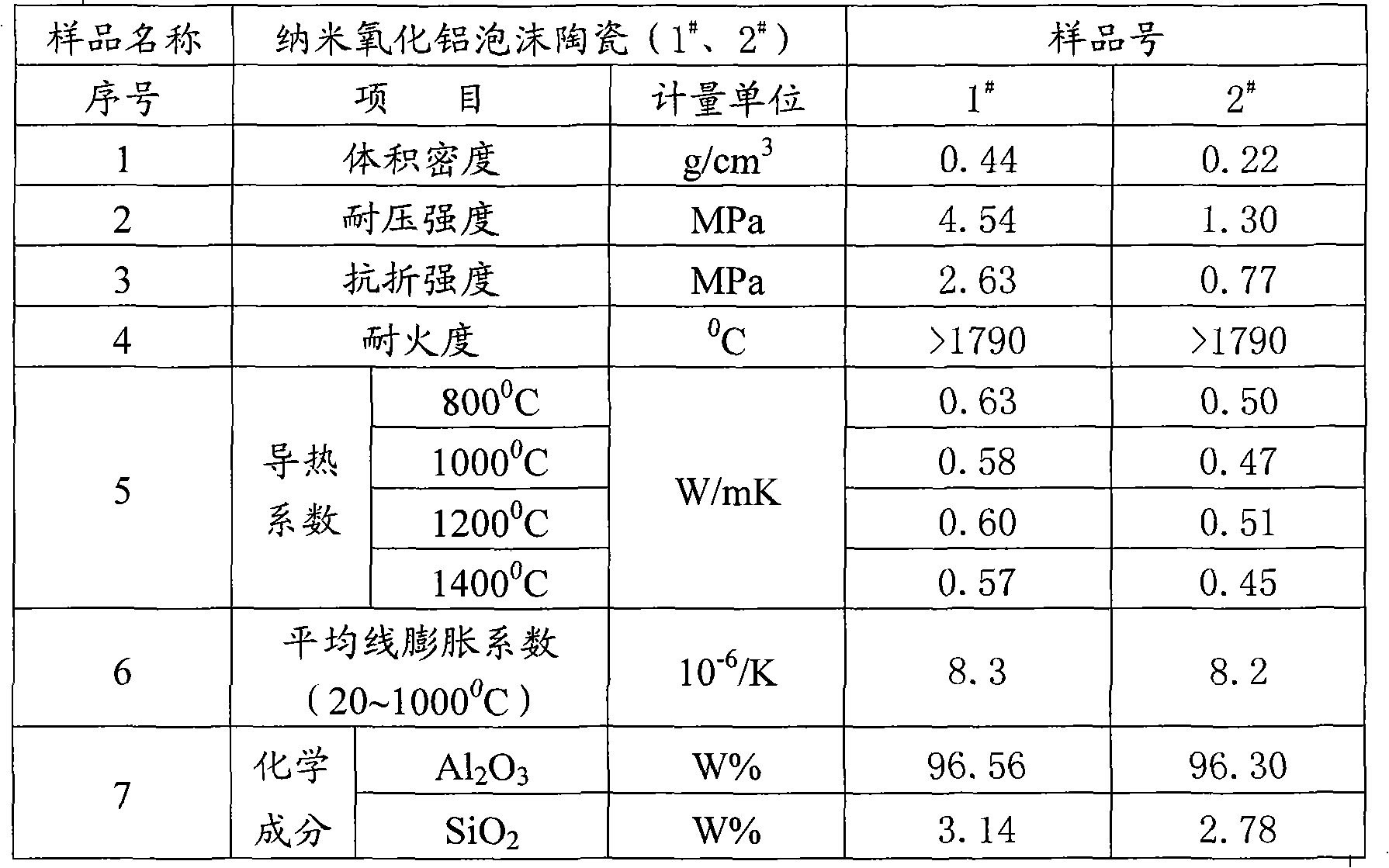

[0026] Table 1 is the performance test report of the nano-alumina foamed ceramics obta...

Embodiment 3

[0031]Take by weighing 500g, the commercially available 99.9% nanometer aluminum oxide that particle size is 200nm, take by weighing 250g (250ml) deionized water, take by weighing 12g purity and be the valeric acid solution of 99.5%, pour in the ball mill tank of 5L, add and material volume 1: 1 agate balls, put the ball mill pot into the ball mill and grind and stir for 4 hours to form a stable suspension of particles; weigh the suspension weight to be 748g, add 150g of pentane with a purity of 98% in the suspension, Form the microemulsion of " oil in water " structure after fully stirring; Inject this microemulsion in the mold identical with embodiment 1, the microemulsion in the mold box is dried 10 days in the constant temperature room of controlling temperature at 50 ℃; After drying The sample connected to the mold was placed in a sintering furnace at 650°C for 8 hours to obtain nano-alumina foam ceramics with a certain strength; after that, the nano-alumina foam ceramics ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com