Diamond fret saw and manufacturing method thereof

A technology of diamond wire saw and manufacturing method, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of damaged sharpness and thickened metal layer, and achieve sufficient hardness, high retention, and good sharpness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

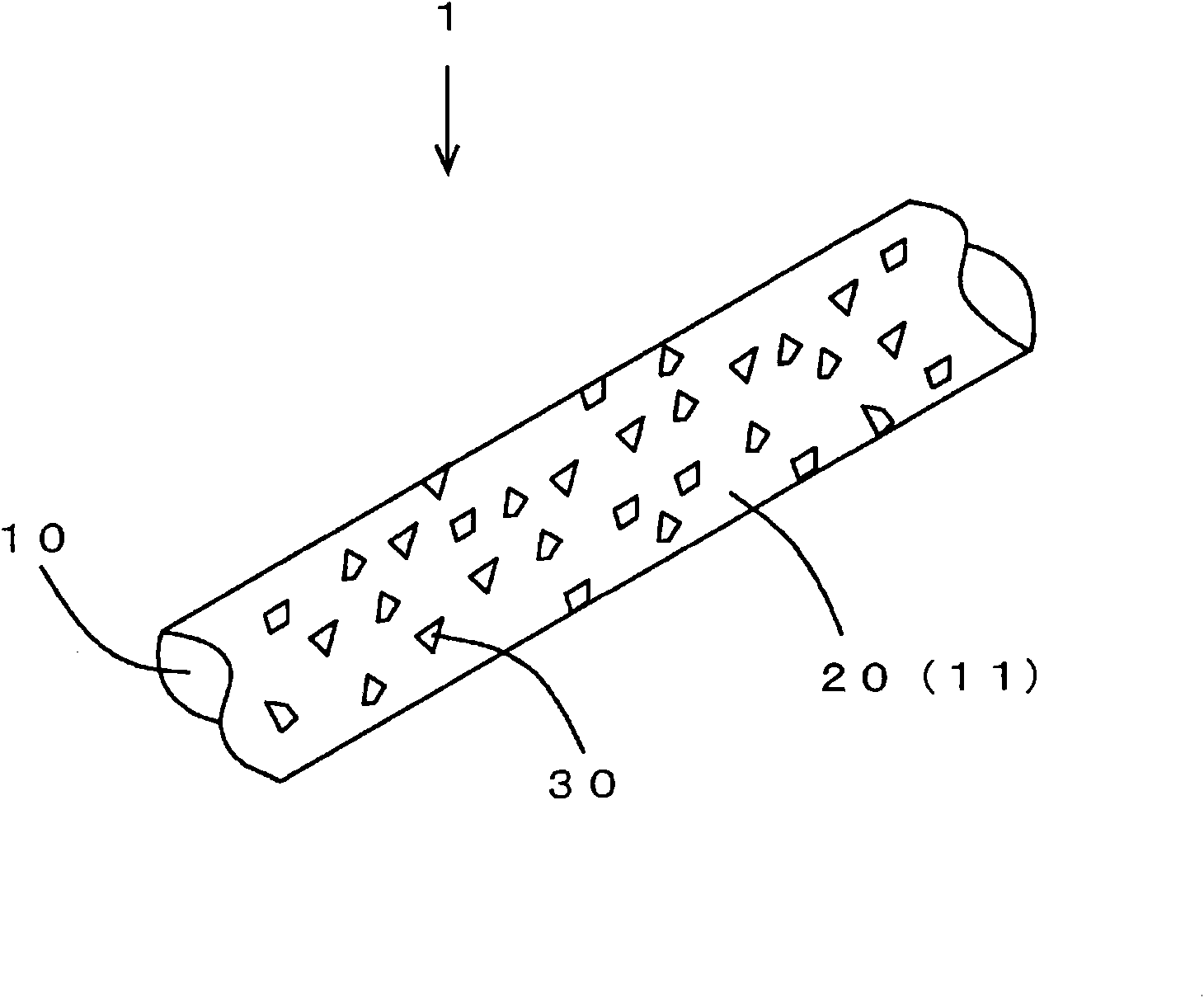

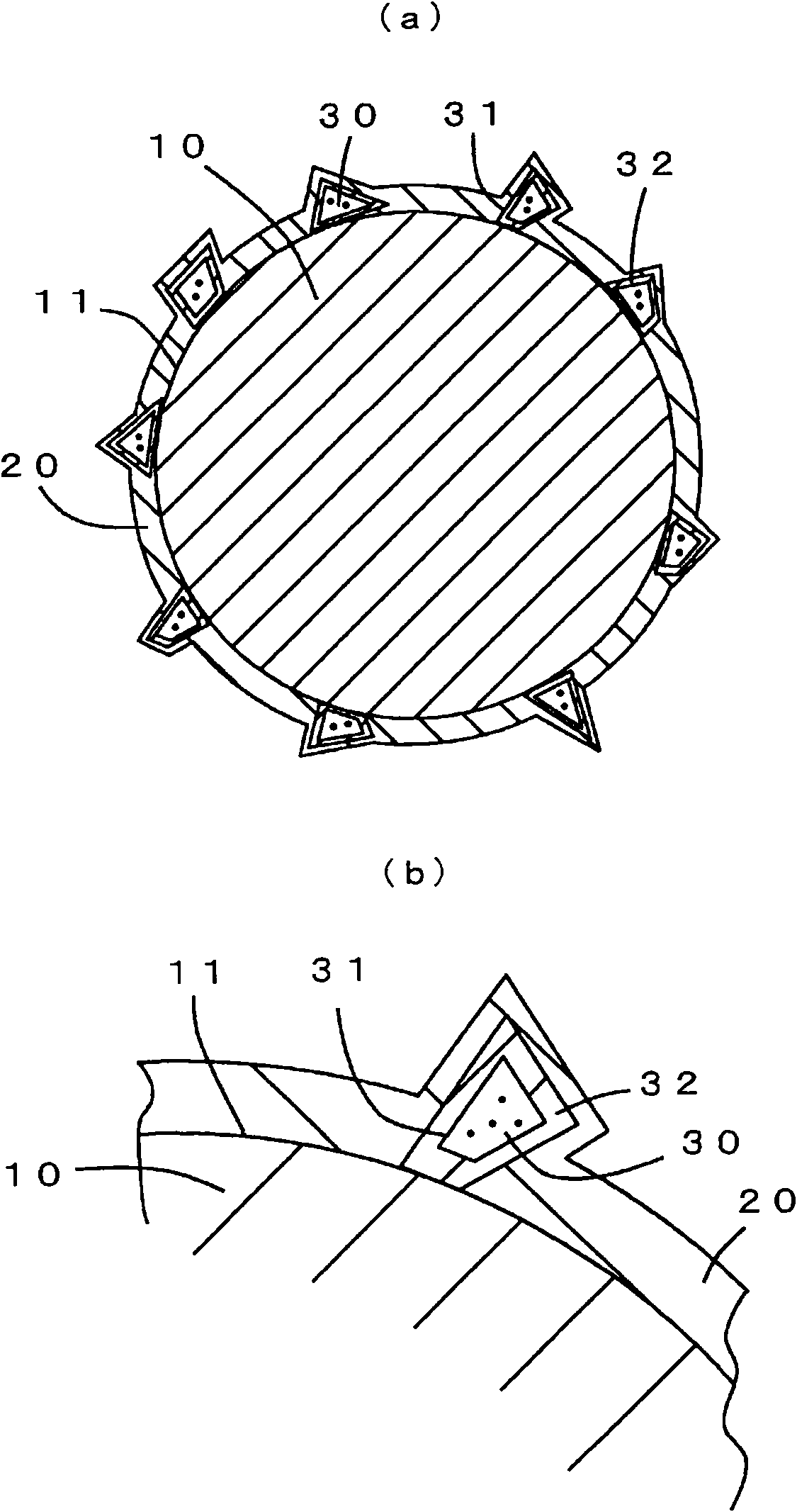

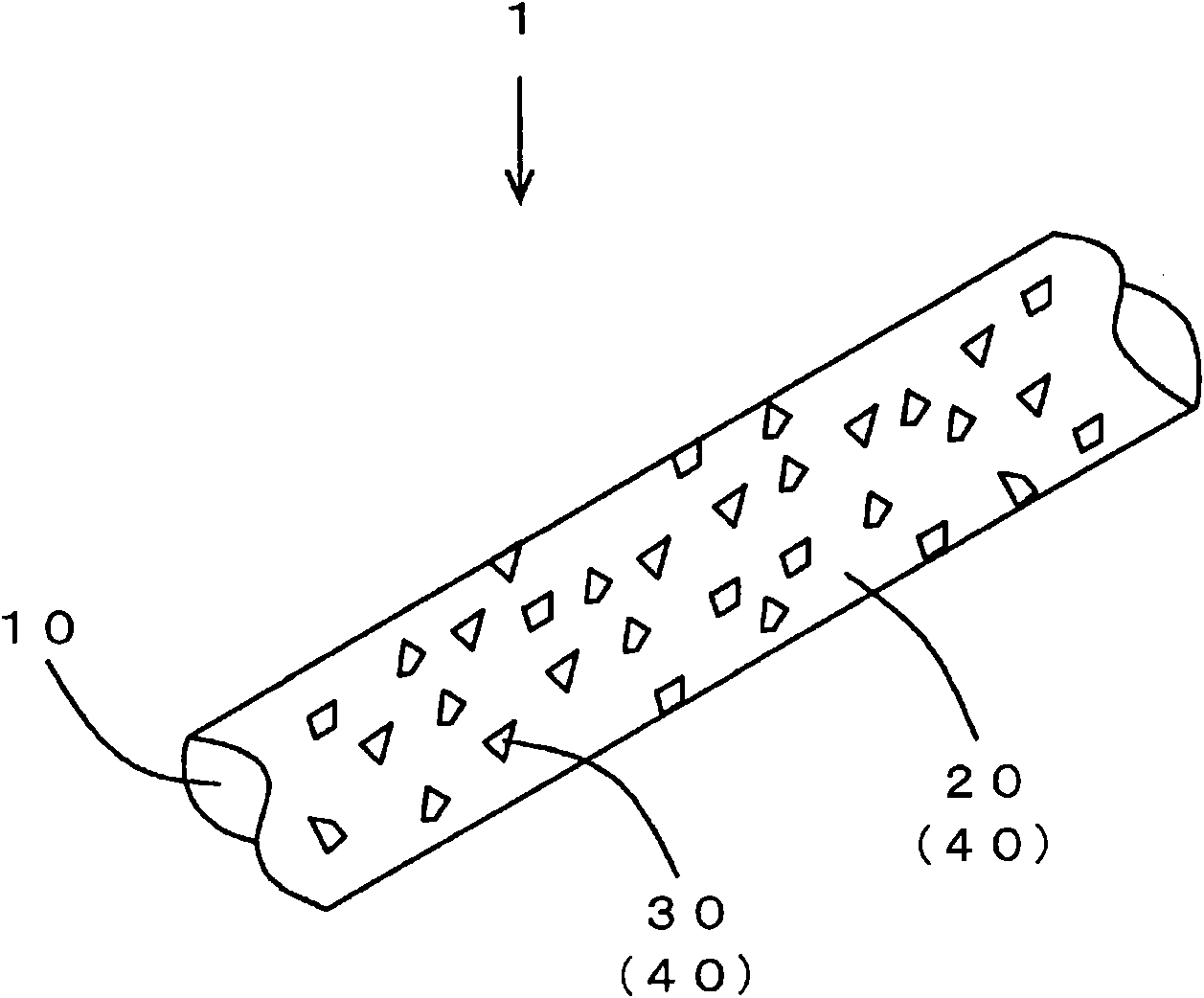

[0087] First, refer to figure 1 , figure 2 , the diamond wire saw according to the first embodiment of the present invention will be described.

[0088] The diamond wire saw 1 of the first embodiment of the present invention, such as figure 1 , figure 2 Shown is a diamond wire saw in which diamond abrasive grains 30 are dispersed and held in a plating layer 20 covering the entire outer surface of a metal core wire 10 .

[0089] The metal core wire 10 may be any metal wire as long as the outer surface 11 can be plated and has a certain strength. For example, steel wires such as piano wires, tungsten wires, molybdenum wires, and the like can be used.

[0090] The diameter of the metal core wire 10 can be appropriately changed according to the material and shape of the material to be cut, but is preferably 0.05 mm to 0.30 mm.

[0091] The coating 20 is as figure 1 , figure 2 As shown, it is used to cover the outer surface 11 of the metal core wire 10 and to disperse and...

Embodiment 1

[0140] Hereinafter, examples are given to describe the present invention in more detail, but the present invention is not limited to these examples.

[0141] pass Figure 5 , Figure 6 In the steps shown, the diamond wire saw 1 is manufactured.

[0142] A long piano wire with a diameter of 0.14 mm is continuously dipped in the degreasing tank 60, the pickling tank 70 and the water washing tank 80 at a conveying speed of 10 m / min to carry out the degreasing treatment, and then the anode chamber 91 and the anode chamber 91 are separated by a cation exchange membrane 91c. The diamond abrasive grain electrodeposition process of electroplating is carried out in the plating tank 90 of the double tank structure of the plating chamber 92 .

[0143] Here, the formulation of the plating bath in the plating tank 90 is: 0.4 mol of diammonium hydrogen citrate, 0.2 mol of sodium formate, 0.2 mol of nickel sulfate, and 0.2 mol of sodium tungstate.

[0144] In addition, the electroplating ...

Embodiment 2

[0149] pass Figure 5 , Figure 6 The process shown, manufactures a diamond wire saw.

[0150] A long piano wire with a diameter of 0.14 mm is continuously immersed in the degreasing tank 60, the pickling tank 70 and the water washing tank 80 at a conveying speed of 10 m / min. Electroplating is performed in a nickel bath obtained by dispersing diamond abrasive grains 30 in a nickel solution.

[0151] Here, the formula of the nickel bath is: nickel sulfate hexahydrate 240g / L, nickel chloride hexahydrate 45g / L, boric acid 30g / L.

[0152] In addition, the electroplating conditions are: bath temperature 50°C, current density 20A / dm 2 , time 1 minute, pH 4.0.

[0153] In addition, as the diamond abrasive grains 30 dispersed in the nickel bath, nickel-plated diamond abrasive grains whose outer surfaces are covered with nickel are used. The amount of nickel plating was 30% by weight based on the diamond abrasive grains, and the average particle diameter of the diamond abrasive gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com