Repeatedly used catalyst for synthesizing dimethyl carbonate

A dimethyl carbonate and catalyst technology, which is applied in the field of flower-like micro-nano structure catalysts for the synthesis of dimethyl carbonate, can solve the problems of reduced catalytic activity, complex catalyst components, and easy loss of catalysts after repeated use, so as to achieve easy expansion and application , the effect of high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

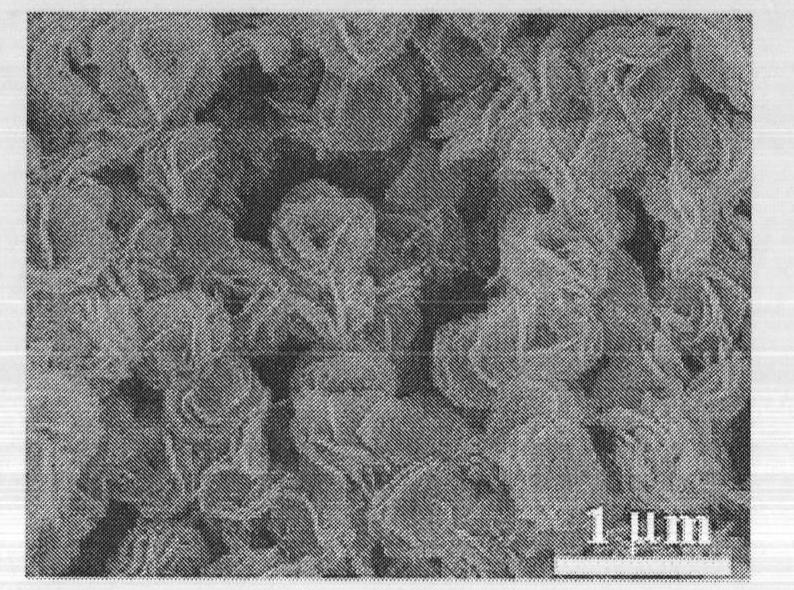

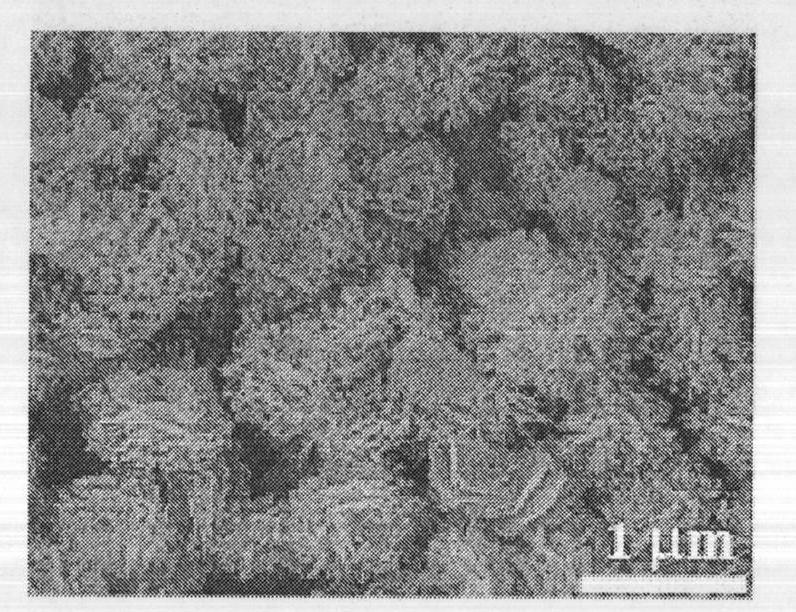

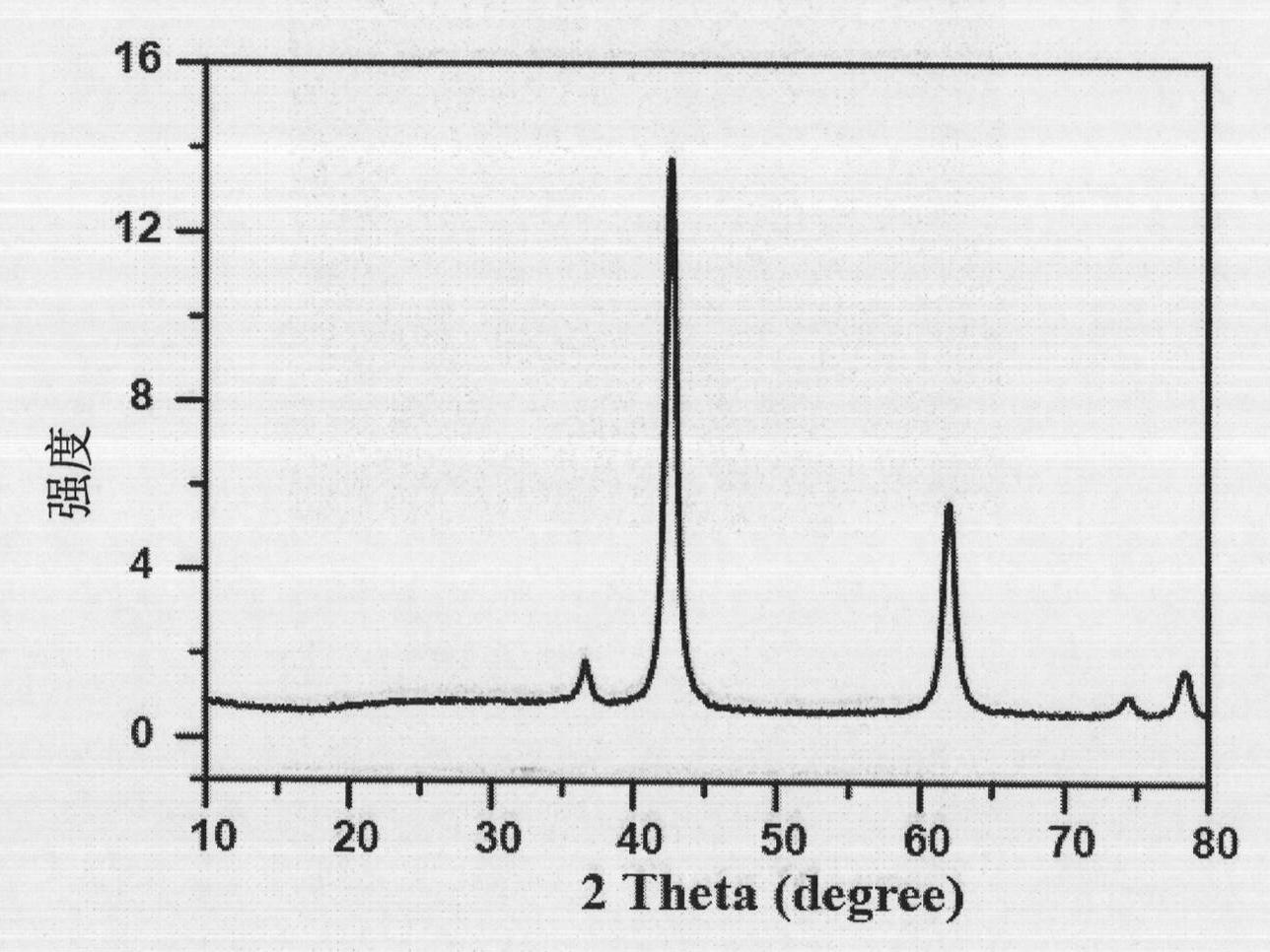

[0032] The ethylene glycol precursor of 0.05g flower-shaped micro-nano structure magnesium oxide is dispersed in the mixed solution of 100mL ethanol and water (ethanol: water=10:1, V / V), then add 0.05g CTAB and 0.18g ammoniacal liquor ( 28%, wt%), after being completely dissolved, add 0.05g tetraethyl orthosilicate, stir for 3 hours to stop the reaction, the product is dried at 50°C after centrifugation, and then roasted at 550°C for 10 hours to obtain a white powdery solid, which is Catalyst for the synthesis of dimethyl carbonate. This white powder is confirmed to be magnesium oxide crystal through X-ray diffraction pattern (see image 3 ), the results of transmission electron microscopy showed that the surface of magnesium oxide with flower-like micro-nano structure was covered with silicon dioxide (see Figure 4 ).

[0033] Get 60 mg of the catalyst and add it to a 25 mL round-bottomed flask, add 4 mL of a mixed solution of ethylene carbonate (or propylene carbonate) and...

Embodiment 2

[0036] 1.0g flower-like micro-nano structure magnesium oxide is dispersed in the mixed solution of 100mL ethanol and water (ethanol: water=1: 10, V / V), then add 0g CTAB and 0.5g ammoniacal liquor (28%, wt%), After complete dissolution, add 0.5 g of methyl orthosilicate and stir for 24 hours to stop the reaction. The product is centrifuged, dried at 80°C, and then calcined at 350°C for 10 hours to obtain a white powdery solid.

[0037] Get 60 mg of the catalyst and add it to a 25 mL round-bottomed flask, add 4 mL of a mixed solution of ethylene carbonate (or propylene carbonate) and methanol (ester: alcohol = 8: 1, mol / mol), react for 6 hours under stirring at 140 ° C, take the bottle The internal products were analyzed by gas chromatography, and the calculation results are shown in Table 1.

[0038] After the catalyst was centrifuged, it was washed three times with methanol and then re-added to carry out the above reaction. After repeating this for 9 times, the product after t...

Embodiment 3

[0040]The ethylene glycol precursor of 0.4g flower-like micro-nano structure magnesium oxide is dispersed in the mixed solution of 100mL ethanol and water (ethanol: water=2: 3, V / V), then add 0.2g CTAB and 0.5g ammoniacal liquor ( 28%, wt%), after completely dissolving, add 0.4g propyl orthosilicate, stir for 3 hours to stop the reaction, the product is dried at 80°C after centrifugation, and then roasted at 550°C for 10 hours to obtain a white powdery solid.

[0041] Get 60 mg of the catalyst and add it to a 25 mL round-bottomed flask, add 4 mL of a mixed solution of ethylene carbonate (or propylene carbonate) and methanol (ester: alcohol = 8: 1, mol / mol), react for 6 hours under stirring at 140 ° C, take the bottle The internal products were analyzed by gas chromatography, and the calculation results are shown in Table 1.

[0042] After the catalyst was centrifuged, it was washed three times with methanol and then re-added to carry out the above reaction. After repeating thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com