Catalyst for preparing ultra-high molecular weight polyethylene

A technology of ultra-high molecular weight and catalyst, which is applied in the field of catalyst system for preparing ultra-high molecular weight polyethylene, which can solve the problems of many catalyst preparation steps and unfavorable industrial production, and achieve the effects of good fluidity, reduced application, and favorable industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

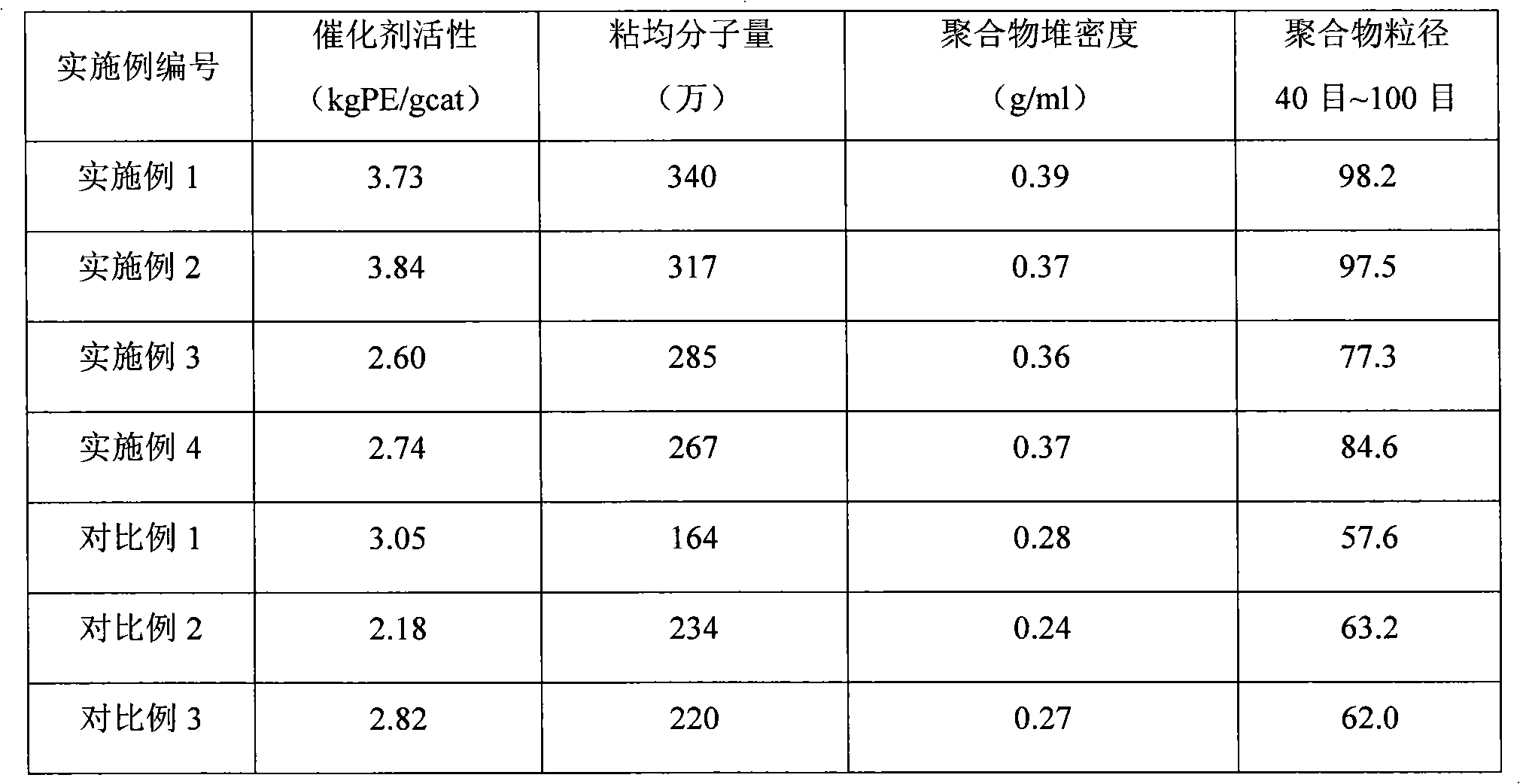

Examples

Embodiment 1

[0025] (1) Preparation of the solid main component of the catalytic body

[0026] Add 2g of magnesium ethoxide and 15ml of isooctyl alcohol into a reactor fully replaced by nitrogen, and feed CO 2, add 0.5ml of dibutyl phthalate, stir for 1 hour, add 15ml of silicon tetrachloride, react for 2 hours, add the mixed liquid dropwise to 20ml of cooled titanium tetrachloride, slowly heat up, react for 2 hours, filter Then add 20ml of mixed solution of titanium tetrachloride and butyl titanate (10:1) to the solid, raise the temperature to 120°C and react for 2 hours, filter, wash the solid catalyst with hexane for 5 times, and dry it in vacuum to obtain the main component of the catalyst solid .

[0027] (2) Polymerization reaction

[0028] Replace the 10L polymerization reactor with nitrogen, add 5000ml of hexane, 0.01mol of triethylaluminum, 20mg of the solid main component of the above catalyst, control the pressure at 1.0MPa, feed ethylene, control the polymerization temperatur...

Embodiment 2

[0030] (1) Preparation of the solid main component of the catalytic body

[0031] Add 3.4g of butylmagnesium and 20ml of 1,3-propanediol into a reactor fully replaced by nitrogen, and feed CO 2 , add 1ml of diisobutyl phthalate, stir for 1 hour, add 18ml of trimethylchlorosilane, react for 2 hours, add the mixed liquid dropwise to 25ml of cooled titanium tetrachloride, slowly heat up and react for 2 hours, After filtering, add 22ml of mixed solution of titanium tetrachloride and butyl titanate (5:1) to the solid, raise the temperature to 120°C for 2 hours, filter, wash the solid catalyst with hexane for 5 times, and dry it in vacuum to obtain the catalyst solid main group. share.

[0032] (2) Polymerization reaction

[0033] Replace the 10L polymerization reactor with nitrogen, add 4000ml of hexane, 0.012mol of triisobutylaluminum, 20mg of the above-mentioned solid main component of the catalyst, control the pressure at 1.0MPa, feed ethylene, control the polymerization tempe...

Embodiment 3

[0035] (1) Preparation of the solid main component of the catalytic body

[0036] Add 3.5g of magnesium chloride and 18ml of ethylene glycol into a reactor fully replaced by nitrogen, and feed CO 2 , add 3ml tetrahydrofuran, stir for 1 hour, add 20ml trimethoxychlorosilane, react for 2 hours, add the mixed liquid dropwise to 25ml cooled titanium tetrachloride, slowly heat up and react for 2 hours, filter and add 25ml A mixed solution of titanium tetrachloride and butyl titanate (10:1) was heated to 120°C for 2 hours, filtered, and the solid catalyst was washed 5 times with hexane, and vacuum-dried to obtain the main catalyst solid component.

[0037] (2) Polymerization reaction

[0038] Replace the 10L polymerization reactor with nitrogen, add 5000ml hexane, 0.015mol monochlorodiethylaluminum, 20 mg of the above-mentioned solid main component of the catalyst, control the pressure at 1.0MPa, feed ethylene, control the polymerization temperature at 72°C, and polymerize In 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com