Propargyl ether modified silicon-containing aryne resin

A technology of propargyl ether and siliaryne, which is used in the field of modified siliaryne resins, can solve the problems of high brittleness, unfavorable resin processing, poor mechanical properties of composite materials, etc., and achieves low cost and excellent processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] (2) Preparation of silicon-containing aryne resin:

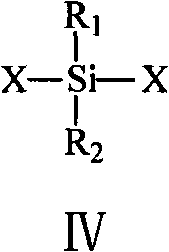

[0039] The main method for preparing the silicon-containing aryne resin of the present invention is to use Grignard reagents to react with halosilanes. The specific process is as follows: first, magnesium and halogenated alkanes are used as raw materials, and anhydrous ether reagents are used as solvents to prepare Aliphatic hydrocarbon Grignard reagent; secondly, with ethynyl arene and diethynyl arene as reactant (the preparation method is referring to CN 1680229 and CN 1680228), ether reagent is used as solvent to form alkyne lattice under the action of aliphatic Grignard reagent The third, alkyne Grignard reagent and dihalosilane (said dihalosilane is selected from one, two or more than two mixtures of compounds shown in formula IV) reaction to prepare silicon-containing aryne resin.

[0040]Wherein: the ether solvent used can be ether, propyl ether, butyl ether, dioxane, tetrahydrofuran (THF) or crown ether. The...

Embodiment 1

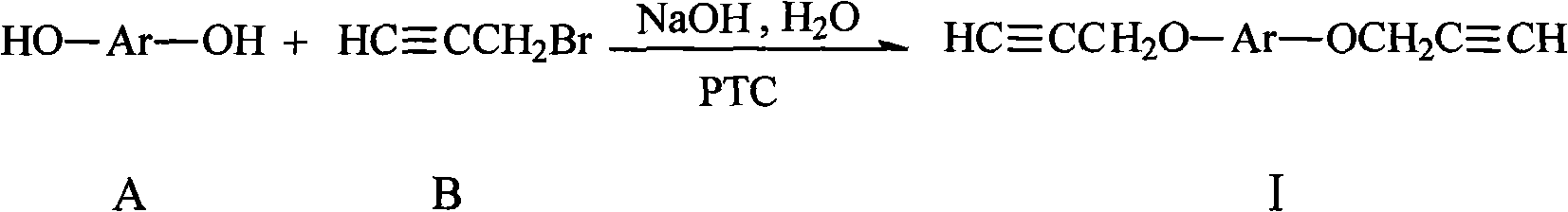

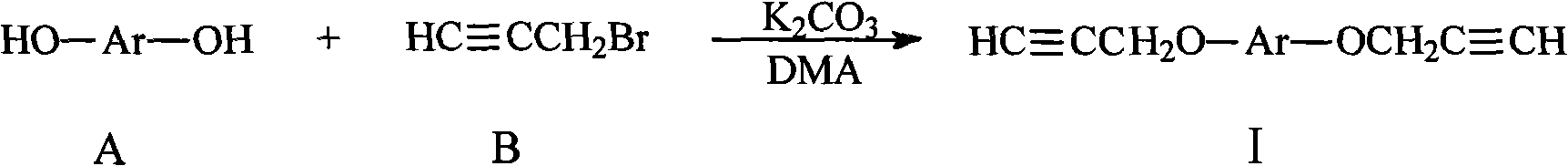

[0052] 1. Synthesis of bisphenol A dipropargyl ether (DPBPA)

[0053] Add 45.60 g (0.20 mol) of bisphenol A, 19.20 g (0.48 mol) of sodium hydroxide, and 0.80 g of benzyltriethylammonium chloride into a 250 ml four-necked round-bottomed flask equipped with a stirring device, a nitrogen inlet tube, and a condenser tube. g and 120ml of deionized water. The temperature of the reaction material was raised to 70°C under stirring, and 59.50 g (0.50 mol) of propyne bromide was added dropwise within 2 hours. After the reaction, the product was washed with water until neutral, and then recrystallized twice with methanol to obtain a light yellow crystal product with a yield of 75%, m.p.79-80°C.

[0054] 1 H-NMR (CDCl 3 , TMS) δ: 1.62 (s, 6H, -CH 3 ), 2.50(tr, 2H, ≡CH), 4.65(d, 4H, -CH 2 ), 6.86 (m, 4H, -O-Ar-H), 7.15 (m, 4H, -C-Ar-H); FT-IR (KBr): 3286cm -1 (≡C-H), 2110cm -1 (C≡C); elemental analysis (C 21 h 20 o 2 ) [found (calculated)] (%): C 82.19 (82.87), H 6.63 (6.62), O 1...

Embodiment 2

[0062] Resin preparation of bisphenol A dipropargyl ether modified dimethyl silicon-containing aryne resin (DPBPA-DMPSA-50)

[0063] Bisphenol A dipropargyl ether (prepared by the method described in Example 1) 5.0g, dimethyl type silicon-containing aryne resin (prepared by the method described in Example 1) 5.0g, Put it into a reactor equipped with a stirrer, a thermometer and a reflux condenser, pass an inert gas, slowly raise the temperature to 150°C, and start stirring. After the reactants are completely melted and homogeneous, continue stirring for 2 hours to obtain a reddish-brown solid resin. In the range of 75-210°C, the viscosity of the resin is less than 0.4Pa.s, and under the condition of higher than 210°C, the viscosity of the resin rises rapidly and begins to gel.

[0064] The resin was cured at 150°C for 2.0h, 170°C for 2.0h, 210°C for 2.0, and then post-treated at 250°C for 4.0h. The glass transition temperature of the cured product was 487°C. Under nitrogen at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com