4032 alloy alterant and use method thereof

A modifier and alloy technology, applied in the field of metallurgy, can solve the problems of less research on the modification treatment of 4032 alloy, insignificant spheroidization effect, and insignificant spheroidization effect, and achieve uniform distribution of AlP particles, improved microstructure and properties, and improved microstructure and properties. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

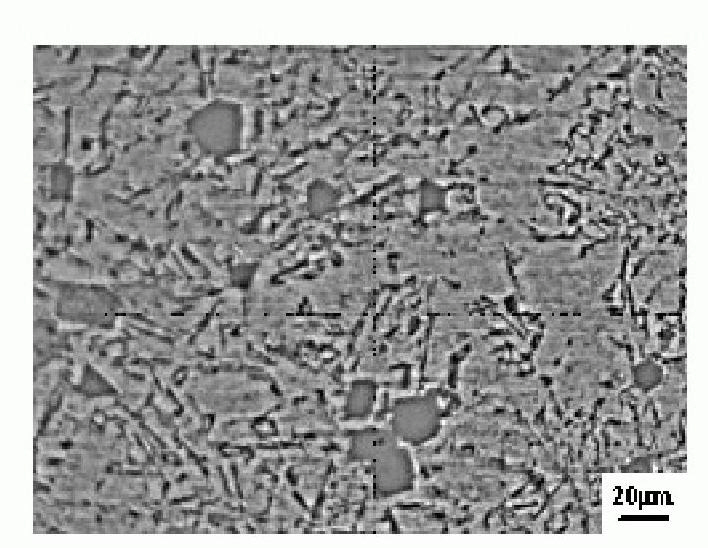

Embodiment 1

[0030] Weigh 1000 grams of ingredients, put a high-purity graphite crucible in a 5KW crucible resistance furnace and preheat it to 760 ° C, add 271.77 grams of industrial pure aluminum (99.97%) and 613.2 grams of Al-20.5% Si, 22.68 grams of Al-40 %Cu, 90g Al-10%Ni, at the same time evenly sprinkled with 45%NaCl+30%KCl+25%Na 3 AlF 6 Cover with the composed flux, after about half an hour, the metal melts, press down 10.5g of pure Mg wrapped in aluminum foil with a bell jar and pour it into the bottom of the molten pool until it is completely melted, take out the bell jar, stir fully, let it stand for 5min, and wrap it in aluminum foil 8 grams of C 2 Cl 6 and 2 g Na 2 SiF 6 The mixed powder is pressed into the bottom of the molten pool for degassing and refining with a bell jar, and left to stand for 10 minutes to remove the scum on the surface. Adjust the furnace temperature to 780°C, press down 12 grams of Al-3.5%P wrapped in aluminum foil with a bell jar, stir evenly, and...

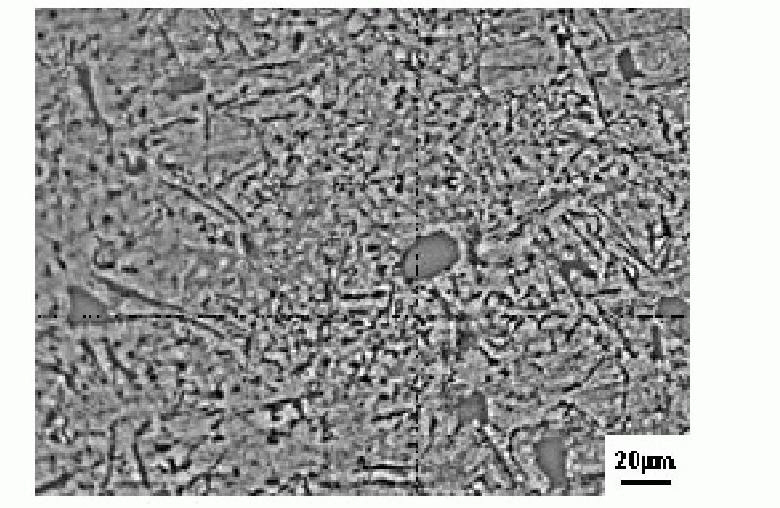

Embodiment 2

[0034] Weigh 1000 grams of ingredients, put a high-purity graphite crucible in a 5KW crucible resistance furnace and preheat it to 760 ° C, add 271.77 grams of industrial pure aluminum (99.97%) and 613.2 grams of Al-20.5% Si, 22.68 grams of Al-40 %Cu, 90g Al-10%Ni, at the same time evenly sprinkled with 45%NaCl+30%KCl+25%Na 3 AlF 6 Cover with the composed flux, after about half an hour, the metal melts, press down 10.5g of pure Mg wrapped in aluminum foil with a bell jar and pour it into the bottom of the molten pool until it is completely melted, take out the bell jar, stir fully, let it stand for 5min, and wrap it in aluminum foil 8 grams of C 2 Cl 6 and 2 g Na 2 SiF 6 The mixed powder is pressed into the bottom of the molten pool for degassing and refining with a bell jar, and left to stand for 10 minutes to remove the scum on the surface. Adjust the furnace temperature to 800°C, press down 8 grams of Al-3.5%P wrapped in aluminum foil with a bell jar, stir evenly, and ...

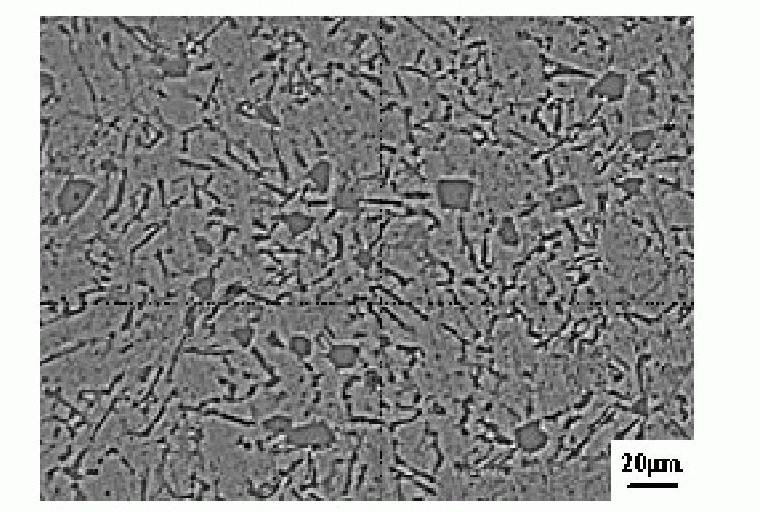

Embodiment 3

[0038] Weigh 1000 grams of ingredients, put a high-purity graphite crucible in a 5KW crucible resistance furnace and preheat it to 760 ° C, add 271.77 grams of industrial pure aluminum (99.97%) and 613.2 grams of Al-20.5% Si, 22.68 grams of Al-40 %Cu, 90g Al-10%Ni, at the same time evenly sprinkled with 45%NaCl+30%KCl+25%Na 3 AlF 6 Cover with the composed flux, after about half an hour, the metal melts, press down 10.5g of pure Mg wrapped in aluminum foil with a bell jar and pour it into the bottom of the molten pool until it is completely melted, take out the bell jar, stir fully, let it stand for 5min, and wrap it in aluminum foil 8 grams of C 2 Cl 6 and 2 g Na 2 SiF 6 The mixed powder is pressed into the bottom of the molten pool for degassing and refining with a bell jar, and left to stand for 10 minutes to remove the scum on the surface. Adjust the furnace temperature to 780°C, press down 12 grams of Al-3.5%P wrapped in aluminum foil with a bell jar, stir evenly, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com