Method for preparing metallic submicron microsphere array film and electric deposition device

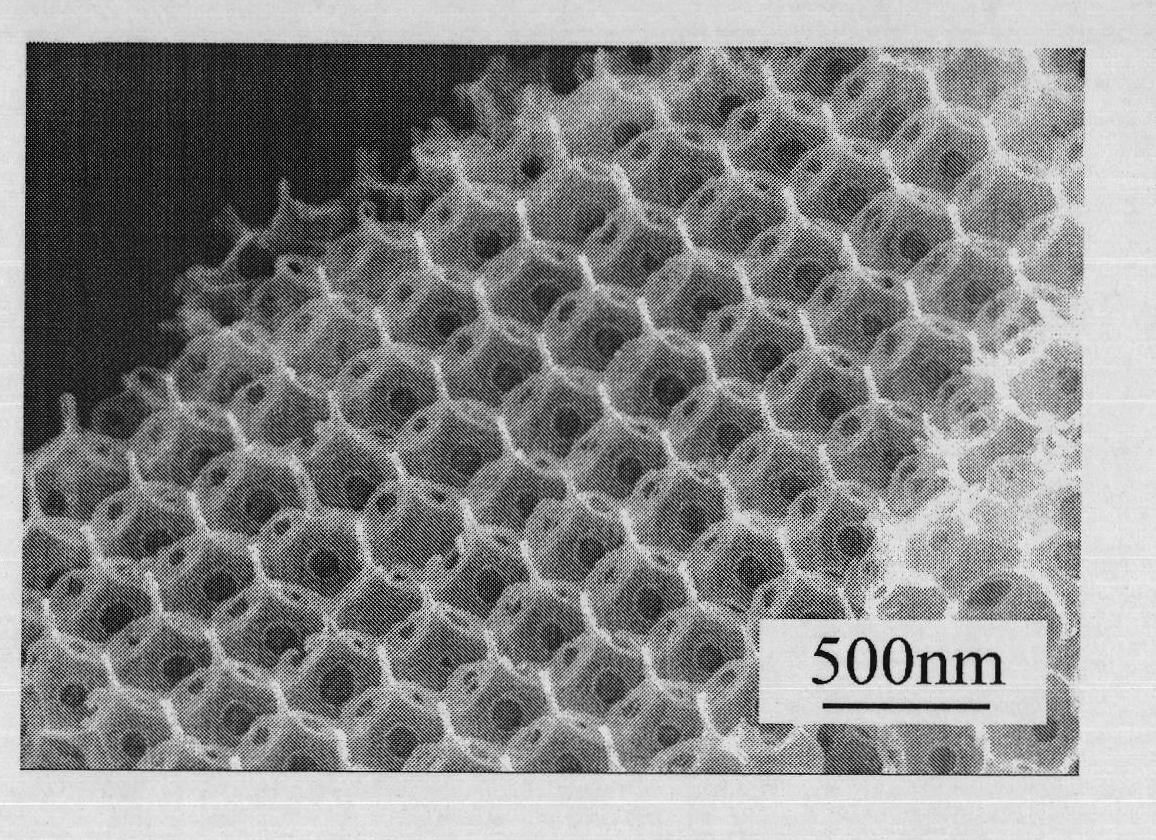

A microsphere array and submicron technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of inability to prepare highly ordered metal submicron microsphere array films, shedding, etc., and achieve easy repeatability and control , Uniform size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

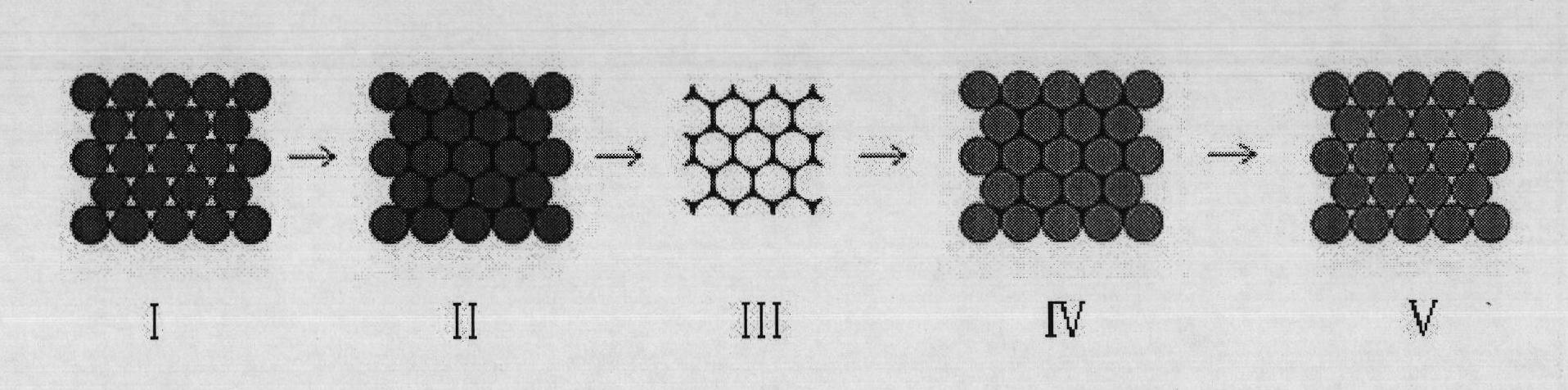

Method used

Image

Examples

example 1

[0038] Example 1, preparation of metal silver submicron microsphere array film

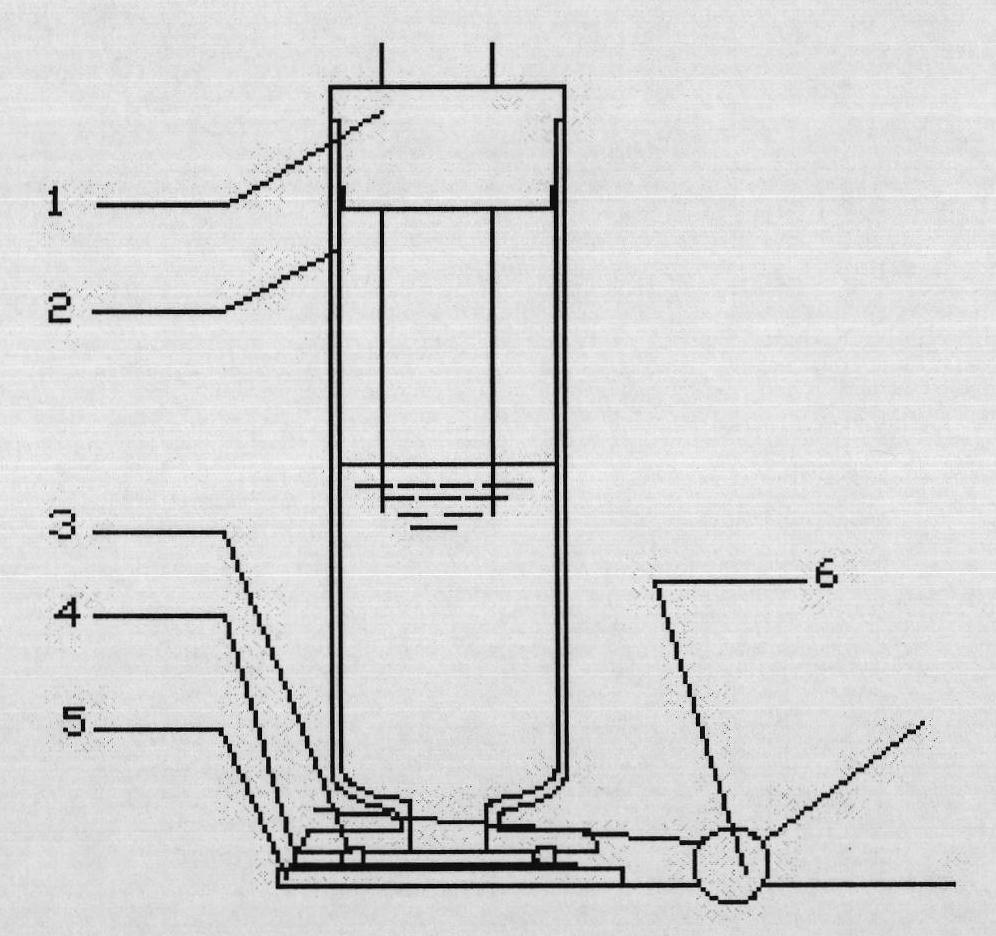

[0039] The present invention provides an electrochemical deposition device. The device as figure 2 Shown: 1. is the rubber stopper containing the electrode, 2. is the glass tube containing the electroplating solution, 3. is the O-ring for sealing, 4. is the silica inverse opal template for electroplating, 5. is Tin dioxide-doped fluorine-doped conductive glass, 6, is the clip that conductive glass and glass are clamped. The glass tube is connected up and down and fixed on the inverse opal template, and the gasket acts as a seal between the bottom of the tube and the sample film. The plating process takes place in the sample inside the O-ring.

[0040] The specific steps of the method for preparing a submicron metal silver ball array thin film using the above-mentioned device are:

[0041] (1) Synthesis of monodisperse polystyrene submicron spheres. Using the soap-free emulsion polymerization...

example 2~3

[0051] Examples 2-3, preparation of metallic nickel submicron microspheres and platinum submicron microsphere array films

[0052] According to the method in Example 1, nickel submicron microspheres and platinum submicron microsphere array films were prepared, and the electroplating solution was replaced with the corresponding formula.

[0053] The nickel electroplating solution is an aqueous solution, and its composition is: nickel chloride 12.5g / L, boric acid 23g / L, nickel sulfate 8.2g / L, and the deposition current density is 0.2mA / cm 2 According to formula 1, the time for electroplating a 4 μm thick nickel ball array film is calculated as 61.6 min.

[0054] Composition of platinum electroplating solution: 0.2408g chloroplatinic acid, 7ml ethanol, 10ml deionized water, deposition current density 0.06mA / cm 2 According to formula 1, the time for electroplating a metal platinum film with a thickness of 4 μm is 62 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com