Conductive polymer aerogel and preparation method thereof

A conductive polymer and aerogel technology, applied in the field of aerogel and its preparation, can solve the problems of poor optical transparency and low brittleness, and achieve the effects of low cost, flexible preparation method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

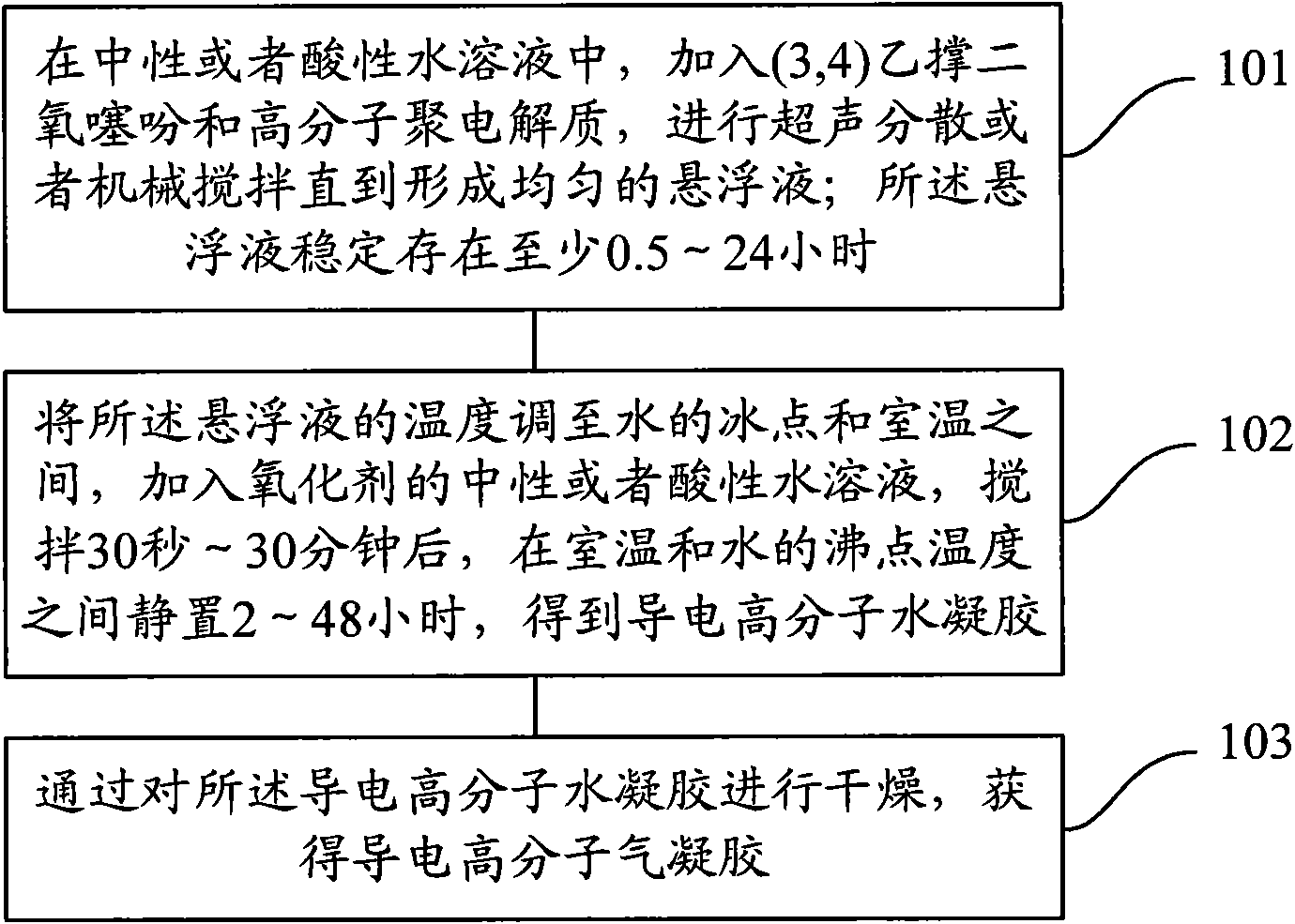

[0032] refer to figure 1 , showing a flow chart of an embodiment of a method for preparing a conductive polymer airgel of the present invention, including:

[0033]Step 101, in a neutral or acidic aqueous solution, add (3,4) ethylenedioxythiophene and a polymer polyelectrolyte, perform ultrasonic dispersion or mechanical stirring until a uniform suspension is formed; the suspension exists stably at least 0.5- 24 hours;

[0034] The aqueous solution selected in the embodiment of the present invention can be a neutral aqueous solution or an acidic aqueous solution, wherein the acidic aqueous solution can be prepared with hydrochloric acid, sulfuric acid or phosphoric acid, and the concentration can be 0.05-4.0 mol / liter.

[0035] In a preferred embodiment of the present invention, the polymer polyelectrolyte is selected from: water-soluble polyacrylic acid salt, polystyrene sulfonate, polyaniline sulfonate, poly(2-acrylamido-2-methyl -1-propanesulfonate), water-soluble anionic...

example 1

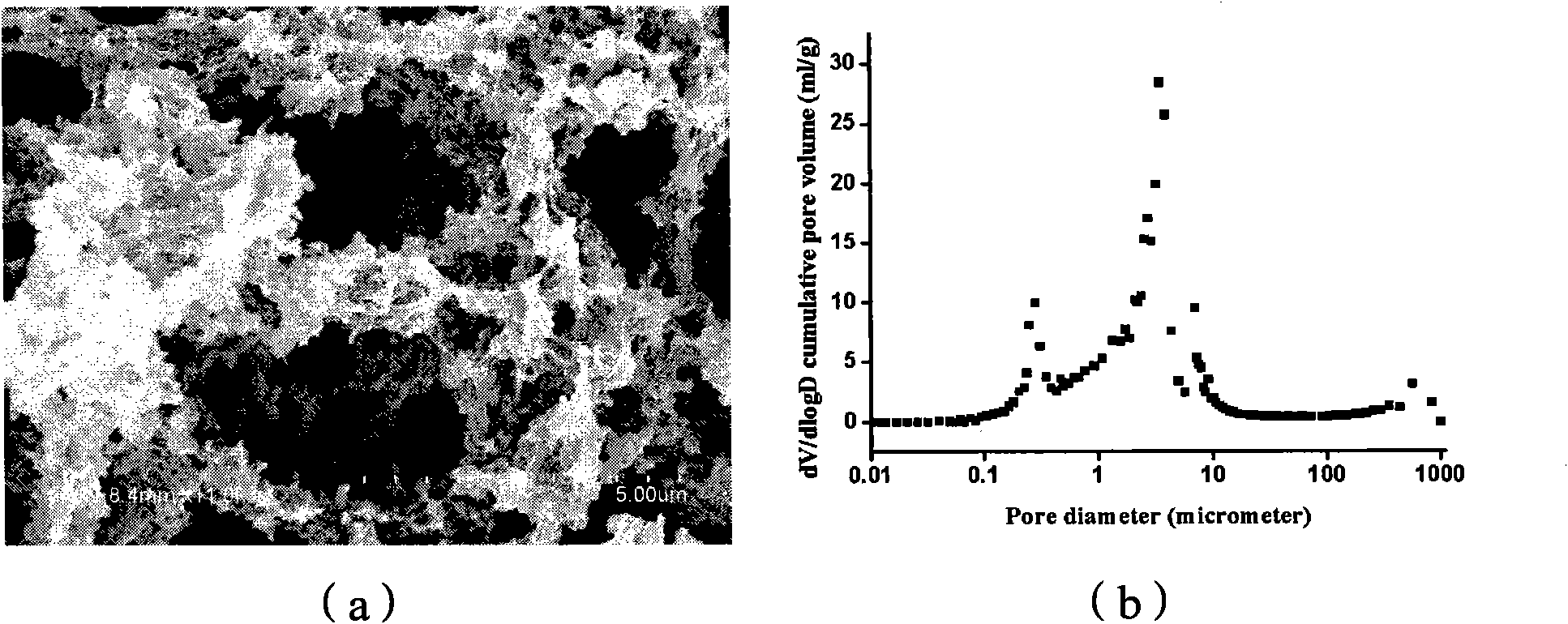

[0046] Example 1, the synthesis of conductive polymer airgel (drying by freeze-drying)

[0047] Take 150uL (3,4)-ethylenedioxythiophene and add it to the sodium polystyrene sulfonate solution (0.56 g sodium polystyrene sulfonate is dissolved in 9 ml of 1 mol / L hydrochloric acid solution), and ultrasonically disperse to form a suspension (emulsion), then add an oxidizing agent solution (3.6 grams of anhydrous cerium nitrate dissolved in 2 milliliters of deionized water), stir vigorously for 30 seconds, and then stand still for 24 hours to obtain a conductive polymer hydrogel. The obtained hydrogel was replaced with 20 liters of deionized water 10 times to remove impurities. Then directional freezing was used to immerse it in a liquid nitrogen solution at a speed of 5 mm / s. After the freezing was complete, it was vacuum-dried to maintain a vacuum of 60 Pa and a temperature of 30 degrees Celsius. After 24 hours, the conductive polymer airgel was obtained. figure 2 (a) is a sca...

example 2

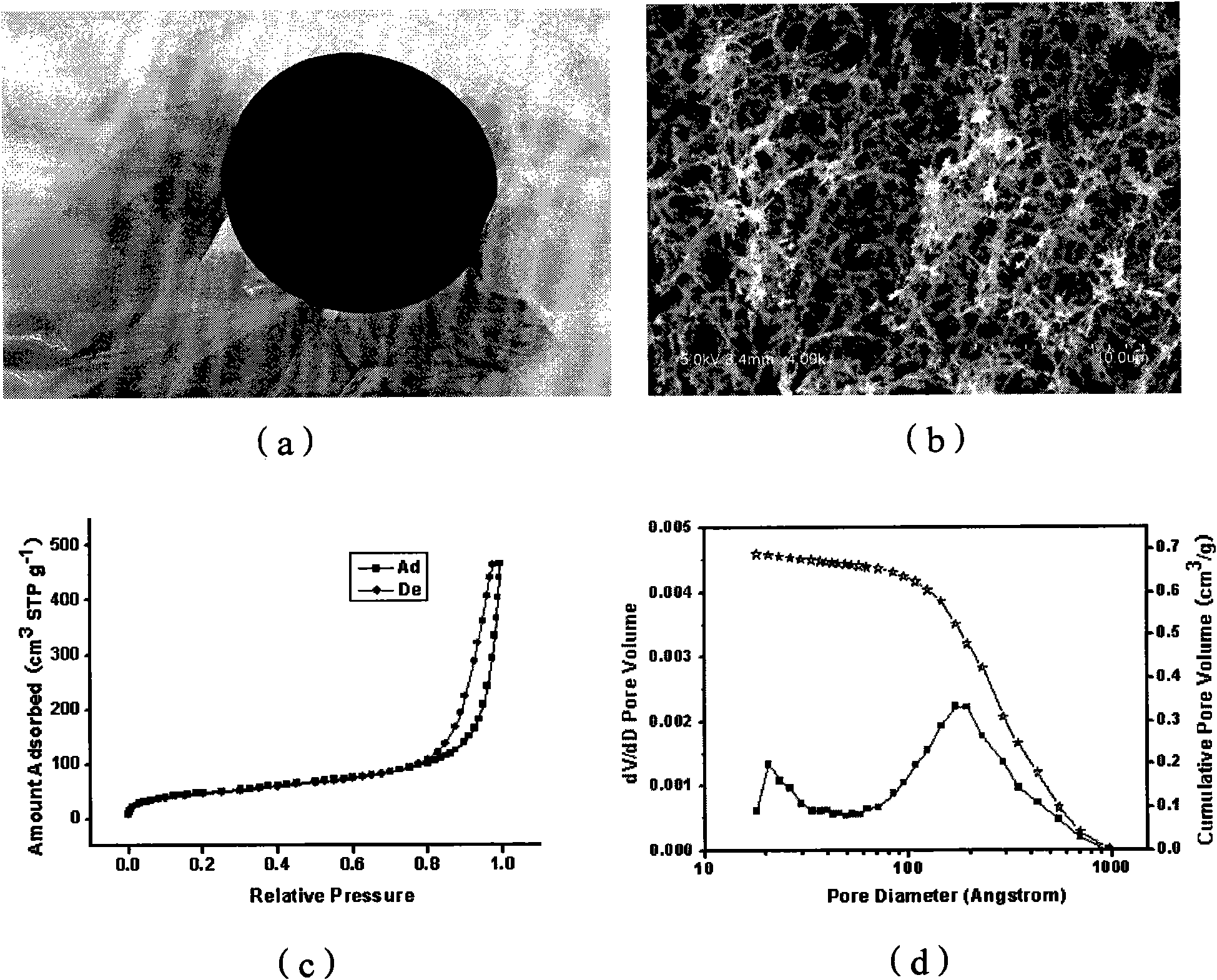

[0049] Example two, the synthesis of conductive polymer airgel (using supercritical drying method)

[0050] Mix 78 μl of (3,4)-ethylenedioxythiophene with sodium polyaniline sulfonate solution (0.151 g of sodium polyaniline sulfonate dissolved in 7.5 ml of deionized water), and stir mechanically for 4 hours to form a suspension (emulsion ), then add an oxidant solution (7.38 grams of ferric nitrate nonahydrate dissolved in 5 milliliters of deionized water), stir vigorously for 1 minute, and then stand at 40 degrees for 12 hours to form a conductive polymer hydrogel. The obtained conductive polymer hydrogel was replaced with 10 liters of deionized water for 5 times in total, and then replaced with 10 liters of ethanol solution for 5 times to obtain the conductive polymer hydrogel. The obtained alcohol gel is dried by supercritical CO2 for 24 hours to obtain the aerogel of conductive polymer. image 3 (a) is a digital photo of the prepared conductive polymer airgel; image 3 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com