Aldehyde group mesoporous molecular sieve used for immobilization of biological enzyme and preparation method thereof

A mesoporous molecular sieve and aldehyde-based mesoporous technology, which is applied in the direction of being fixed on or in an inorganic carrier, can solve the problems of loss of catalytic activity of free enzymes, and achieve the effects of improving operational stability, activity and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] At room temperature, 2.0g Pluronic P123 (EO 20 PO 70 EO 20 ,M av =5800) was dissolved in 75mL of 1.6mol / L HCl solution; after P123 was completely dissolved, 0.023g of ammonium fluoride and 3.0g of 1,3,5-trimethylbenzene were added, then the solution was heated to 35°C and continued to stir for 45min , add 4.4g tetraethyl orthosilicate, and continue to stir at 35°C for 20 hours; transfer the solution into a hydrothermal crystallization kettle with a polytetrafluoroethylene liner, and conduct hydrothermal crystallization at 100°C for 24 hours; After the solution was cooled to room temperature, it was filtered to obtain a white solid, dried overnight in an oven at 100°C, and then calcined in a muffle furnace at a temperature programmed to 550°C for 8 hours to obtain a mesoporous molecular sieve.

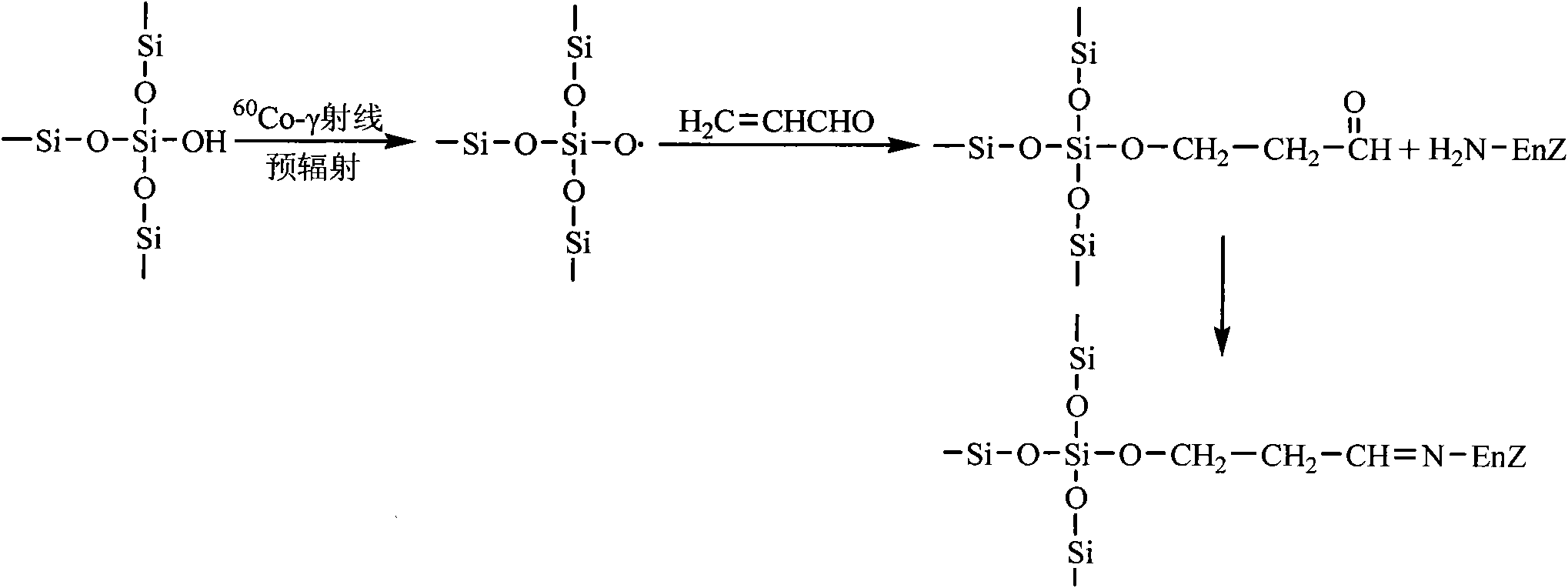

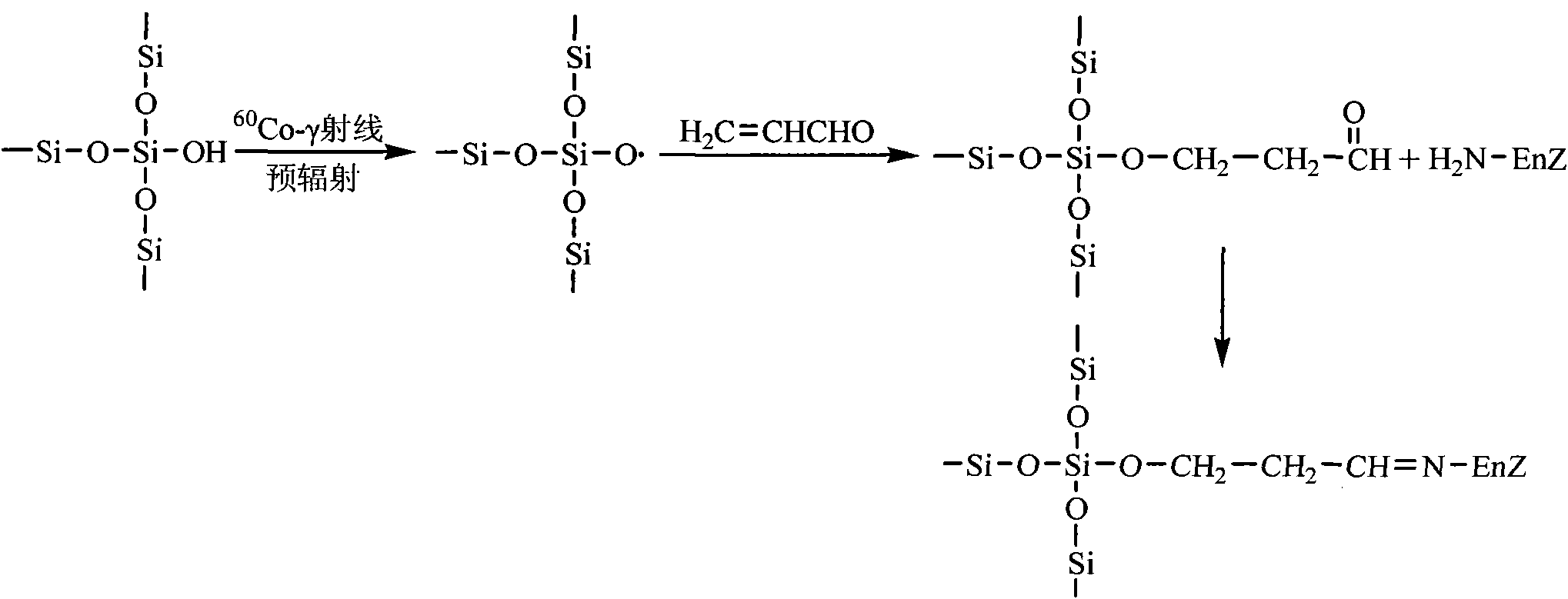

[0036] use 60 Schematic diagram of the functionalization of aldehyde groups on the surface of mesoporous molecular sieves and the immobilization of enzymes by Co-γ-ray pre-ir...

Embodiment 2

[0038] The preparation method of the mesoporous molecular sieve is the same as that of Example 1. Put 1.0g of the above-mentioned mesoporous molecular sieve in 60 Co-γ-ray pre-irradiation, the irradiation dose is 24kGy, the sample is transferred to 50mL 90% acrolein aqueous solution after pre-irradiation, placed in an ice-water bath, vacuumed, filled with nitrogen, and then placed in a water bath at 30 °C React for 30 hours; filter the mesoporous molecular sieve, extract with ethanol in a Soxhlet extractor to remove acrolein polymer, and then dry in a vacuum oven at 75°C for 18 hours to obtain an aldehyde-based mesoporous molecular sieve. The above-mentioned aldehyde-based mesoporous molecular sieve was used to immobilize penicillin acylase, and the activity of the obtained immobilized enzyme was 8760 U / g. After 10 cycles of use, the immobilized enzyme retained 81% of the initial activity.

Embodiment 3

[0040] The preparation method of the mesoporous molecular sieve is the same as that of Example 1. Put 1.0g of the above-mentioned mesoporous molecular sieve in 60 Co-γ-ray pre-irradiation, the irradiation dose is 120kGy, the sample is transferred to 200mL 10% acrolein aqueous solution after pre-irradiation, placed in an ice-water bath, vacuumed, filled with nitrogen, and then placed in a water bath at 80 °C React for 10 hours; filter the mesoporous molecular sieve, extract with ethanol in a Soxhlet extractor to remove the acrolein polymer, and then dry in a vacuum oven at 100° C. for 12 hours to obtain the aldehyde-based mesoporous molecular sieve. The above-mentioned aldehyde-based mesoporous molecular sieve was used to immobilize penicillin acylase, and the activity of the obtained immobilized enzyme was 8920 U / g. After 10 cycles of use, the immobilized enzyme retained 80% of the initial activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com