Method for separating and purifying antifungal lipopeptide

A separation and purification, anti-fungal technology, applied in the field of lipopeptide separation and purification to prevent and control plant fungal diseases, can solve the problems of complex control of process conditions, cumbersome purification steps, poor purification effect, etc., achieve good purification effect, difficult activity, separation and purification The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

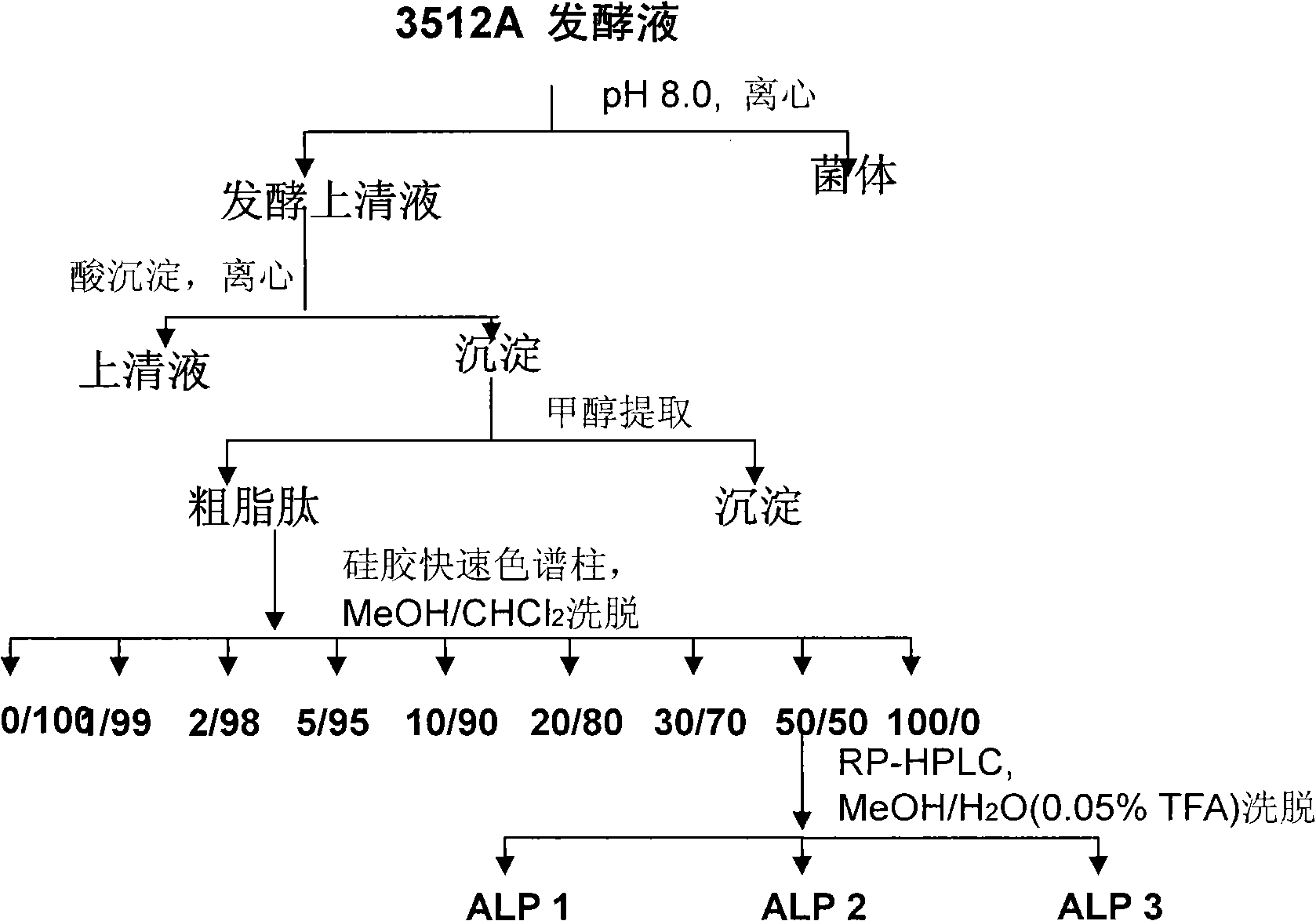

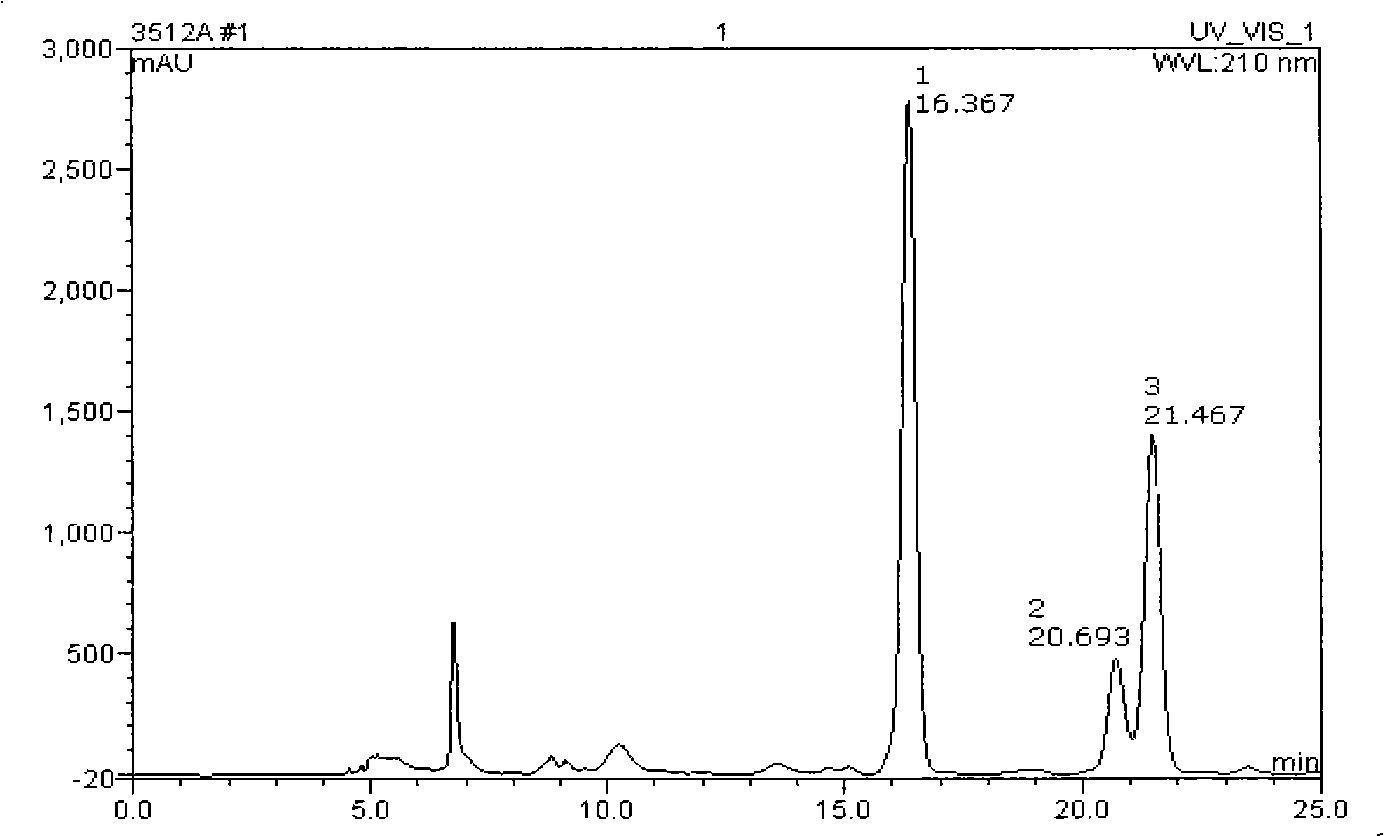

Method used

Image

Examples

Embodiment 1

[0026] Adopt 3 Erlenmeyer flasks of 500ml capacity, each bottle packs 100ml fermentation medium (sucrose 2%, KH 2 PO 4 0.3%, Na 2 HPO 4 1%, NH 4 NO 3 0.2%, MgSO 4 ·7H 2 O 0.02%, yeast powder 0.02%, CaCl 2 0.7μg / 100ml, MnSO 4 ·H 2 O 1μg / 100ml, pH 7.0-7.2, the balance is water), sterilized at 121°C for 30 minutes, after cooling, inoculate a ring of fresh activated antifungal lipopeptide producing bacteria marine Bacillus subtilis 3512A, and place at 28°C In the shaker, shake at 180rpm for 24 hours. After the cultivation, take it out and take it out for microscopic examination. It can be used as the seed solution.

[0027]Inoculate the cultivated seed liquid with an inoculation amount of 5% by volume in a 10L fermentation bioreactor with 6L sterilized fermentation medium inside. 5-7L / min, the stirring speed is 180-210rpm, and the aeration and stirring fermentation can be put into the tank after 46-50 hours of fermentation. This fermentation broth can be used to extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com