Method for preparing fluorobiaryl compound in pure water solution

A pure aqueous solution and compound technology, applied in the field of preparing fluorinated biaryl compounds, can solve the problems of low reactivity, unreported fluorinated biaryl compound methods, long reaction time, etc. Recycling and reuse, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

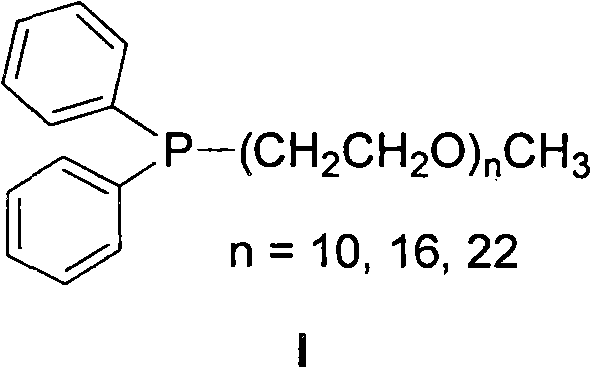

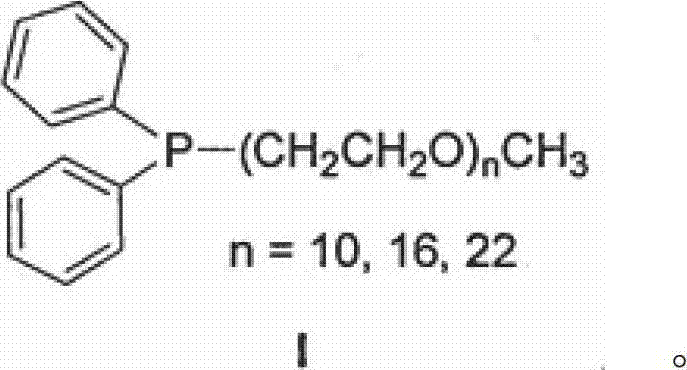

Image

Examples

Embodiment 1

[0013] Example 1 Preparation of 4-(4-fluorophenyl)benzonitrile

[0014] Under the protection of nitrogen, first complex palladium acetate (0.0025mmol), ligand I (n=22, 0.005mmol) and deoxygenated water (1ml) in a Schlink bottle for 30 minutes, and then add triethylamine (1.0mmol) sequentially , 4-bromobenzonitrile (0.5mmol), 4-fluorophenylboronic acid (0.75mmol), reacted under magnetic stirring at 80°C for 1 hour, followed by TLC. After the reaction, add 2ml ether to the reaction mixture for extraction, stand at room temperature and separate the phases, add 15mL saturated brine to the ether phase and extract the reaction product with ethyl acetate (15mL×3), combine the organic phases, anhydrous Na 2 SO 4 Dry, filter, and use a rotary evaporator to concentrate to obtain a crude product. Column chromatography obtains the target product. The eluent used in column chromatography is petroleum ether, and the product structure passes through 1 H NMR and mass spectral identification...

Embodiment 2

[0015] Example 2 Preparation of 4-(4-fluorophenyl)toluene

[0016] Under the protection of nitrogen, first complex palladium acetate (0.0025mmol), ligand I (n=16, 0.005mmol) and deoxygenated water (1ml) in a Schlink bottle for 30 minutes, and then add triethylamine (1.0mmol) sequentially , 4-bromotoluene (0.5mmol), 4-fluorophenylboronic acid (0.75mmol), reacted under magnetic stirring at 80°C for 1 hour, followed by TLC. After the reaction, add 2ml ether to the reaction mixture for extraction, stand at room temperature and separate the phases, add 15mL saturated brine to the ether phase and extract the reaction product with ethyl acetate (15mL×3), combine the organic phases, anhydrous Na 2 SO 4 Dry, filter, and use a rotary evaporator to concentrate to obtain a crude product. Column chromatography obtains the target product. The eluent used in column chromatography is petroleum ether, and the product structure passes through 1 H NMR and mass spectral identification. The sep...

Embodiment 3

[0017] Example 3 Preparation of 4-(4-fluorophenyl)anisole

[0018] Under the protection of nitrogen, first complex palladium chloride (0.0025mmol), ligand I (n=22, 0.005mmol) and deoxygenated water (1ml) in a Schlink bottle for 30 minutes, and then add potassium carbonate (1.0mmol) sequentially , 4-bromoanisole (0.5mmol), 4-fluorophenylboronic acid (0.75mmol), reacted under magnetic stirring at 80°C for 1 hour, followed by TLC. After the reaction, add 2ml ether to the reaction mixture for extraction, stand at room temperature and separate the phases, add 15mL saturated brine to the ether phase and extract the reaction product with ethyl acetate (15mL×3), combine the organic phases, anhydrous Na 2 SO 4 Dry, filter, and use a rotary evaporator to concentrate to obtain a crude product. Column chromatography obtains the target product. The eluent used in column chromatography is petroleum ether, and the product structure passes through 1 H NMR and mass spectral identification. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com