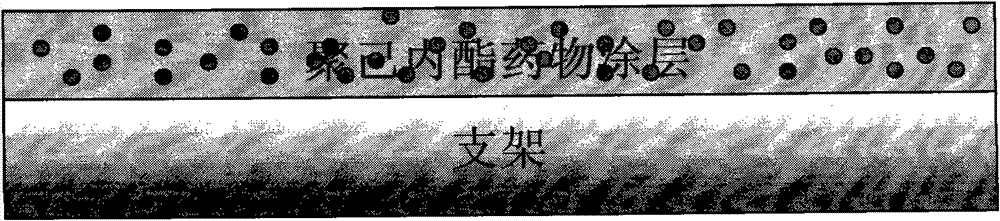

Bracket with drug temperature-sensitive controlled-release function and application thereof

A temperature-sensitive, functional technology, applied in the field of stents, to achieve good temperature sensitivity, inhibition of proliferation, and good effect of controlled drug release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

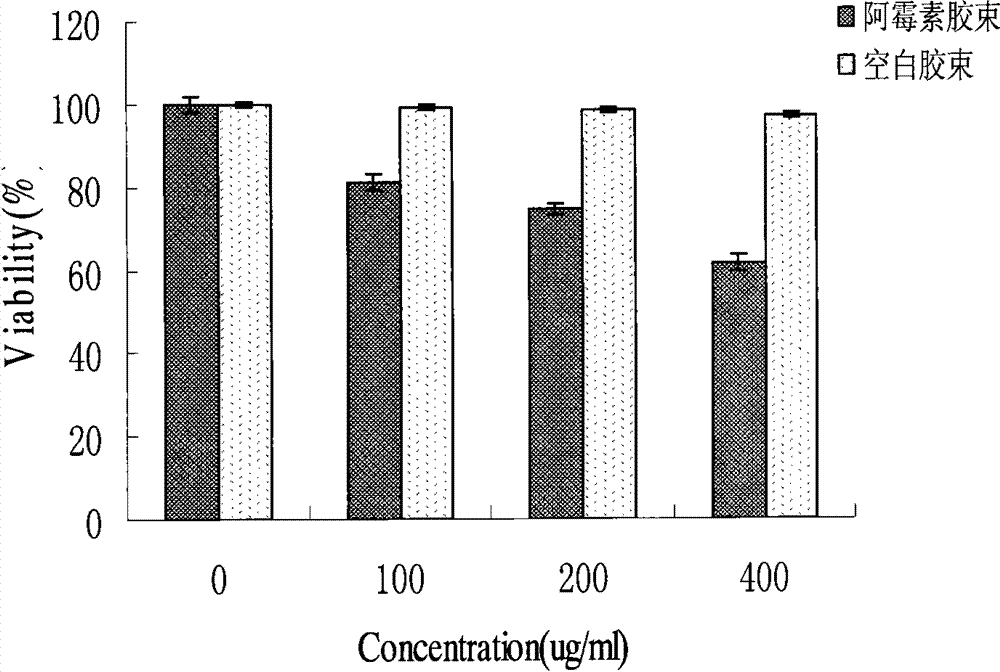

Examples

Embodiment 1

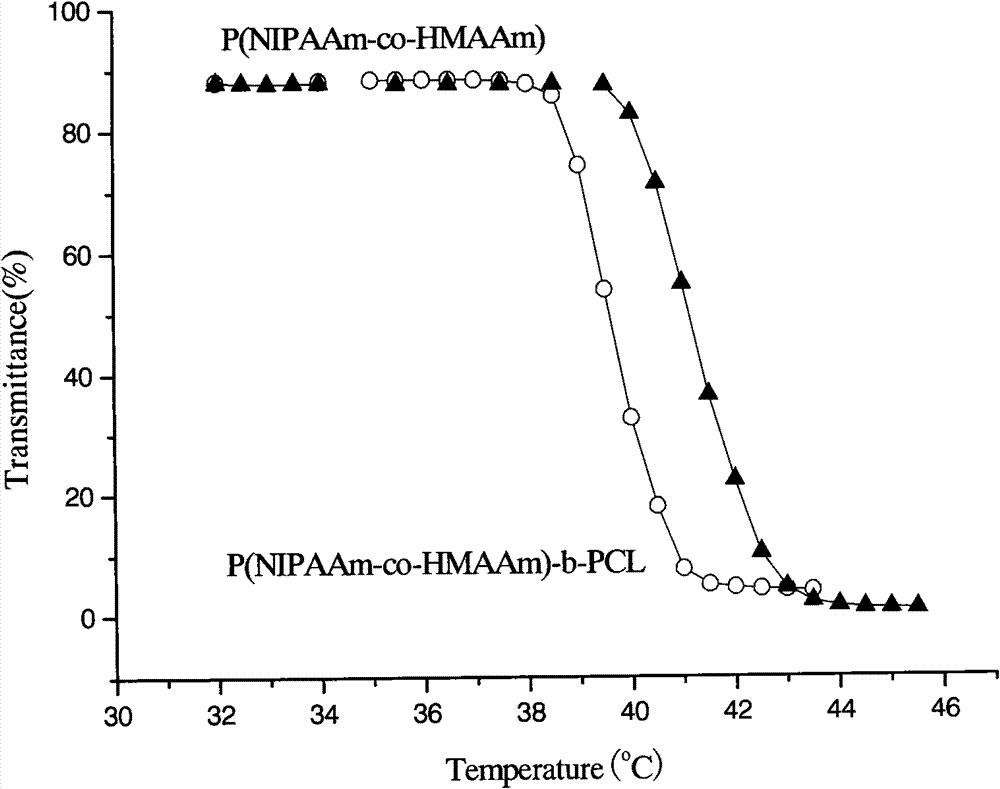

[0036] 1. Preparation of amphiphilic block copolymer of thermosensitive polymer and degradable hydrophobic polymer

[0037] (1) Mix NIPAm and NHMAAm at a ratio of 7mmol: 1mmol, dissolve them in 10ml of tetrahydrofuran (THF), then add 0.04mmol of benzoyl peroxide (BPO) to the solution as an initiator, and 0.08mmol of mercaptoethanol as a chain transfer agent. agent, solution through N 2 Gas 20min;

[0038] (2) Then in N 2 Placed in a constant temperature water bath at 70°C under the protection of , and reacted with electromagnetic stirring for 7 hours;

[0039] (3) After the reaction solution is cooled, remove impurities by suction filtration;

[0040] (4) 8-10 times the volume of diethyl ether is used as a precipitating agent, after several times of dissolution, precipitation, and vacuum drying to obtain a white powder.

[0041] (5) Copolymerize the prepared methylolacrylamide and N-isopropylacrylamide with polycaprolactone (PCL) according to the ratio of 1:4 (molar ratio)...

Embodiment 2

[0051] 1. Preparation of amphiphilic block copolymer of thermosensitive polymer and degradable hydrophobic polymer

[0052] (1) Mix NIPAm and NHMAAm at a ratio of 5mmol: 1mmol, dissolve them in 10ml of tetrahydrofuran (THF), then add 0.04mmol of benzoyl peroxide (BPO) to the solution as an initiator, and 0.10mmol of mercaptoethanol as a chain transfer agent. agent, solution through N 2 Gas 20min;

[0053] (2) Then in N 2 Placed in a constant temperature water bath at 70°C under the protection of , and reacted with electromagnetic stirring for 7 hours;

[0054] (3) After the reaction solution is cooled, remove impurities by suction filtration;

[0055] (4) 8-10 times the volume of diethyl ether is used as a precipitating agent, after several times of dissolution, precipitation, and vacuum drying to obtain a white powder.

[0056] (5) Prepare the copolymer and polycaprolactone (PCL) according to the ratio of 1:6 (molar ratio), and react at 180°C for 24 hours to obtain the desi...

Embodiment 3

[0064] 1. Preparation of amphiphilic block copolymer of thermosensitive polymer and degradable hydrophobic polymer

[0065] The specific method is the same as in Example 1, wherein poly-N-isopropylacrylamide and polylactide (PLA) are proportioned according to 1:1 (molar ratio).

[0066] 2. Preparation of coatings with drug temperature-sensitive controlled release

[0067] Take by weighing 100mg polylactide (PLA) and be mixed with the organic solution that is the tetrahydrofuran of 10-15% concentration by weight percentage, take camptothecin with the medicine / polylactide ratio of 1: 20-1: 30, camptothecin Place in the above solution, mix and stir. Weigh the amphiphilic block copolymer with the amphiphilic block copolymer / polylactide ratio of 1:1-1:15, put the amphiphilic block copolymer in the above solution, mix and stir, and vortex to form a uniform mixed solution .

[0068] 3. Preparation of stents with drug temperature-sensitive controlled release

[0069] A tracheal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com