Maleic anhydride acidation chitosan salt/nature rubber graft copolymer and preparation method thereof

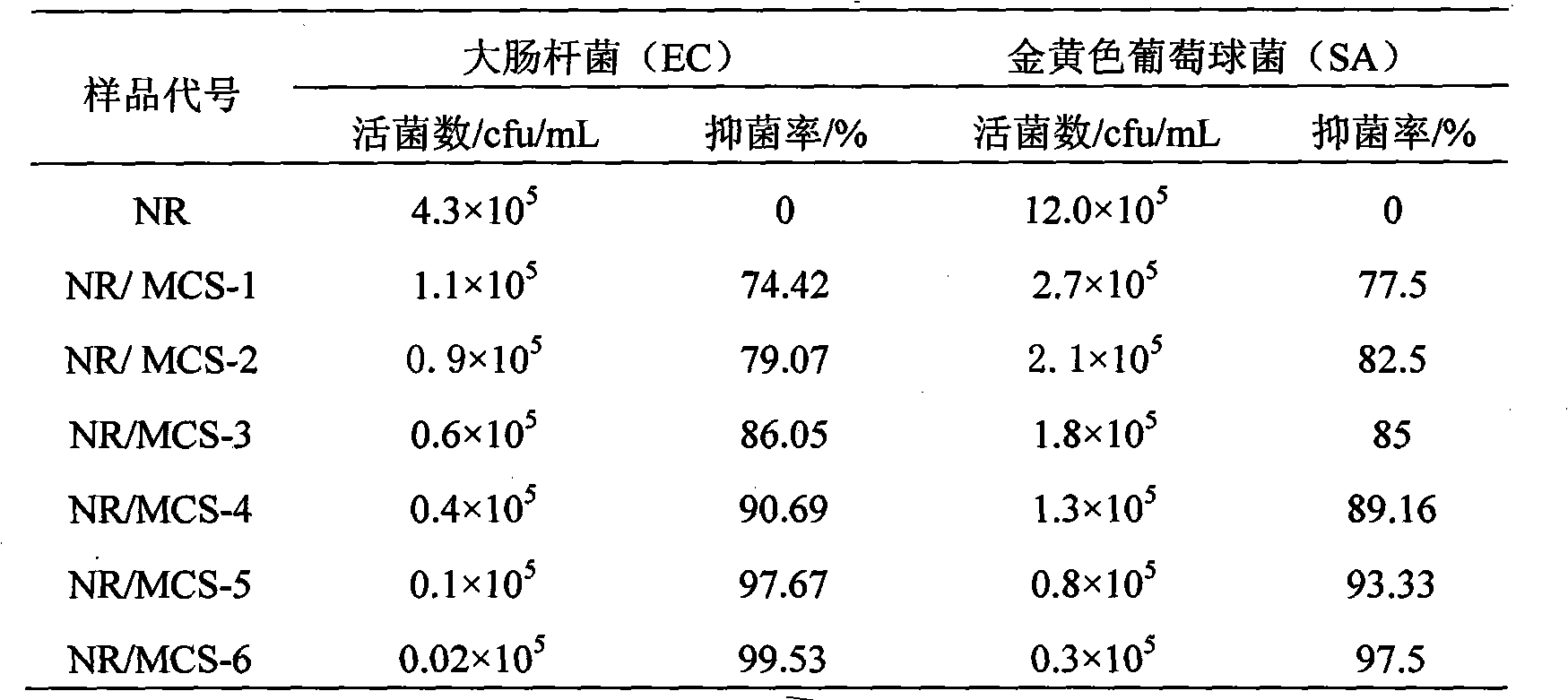

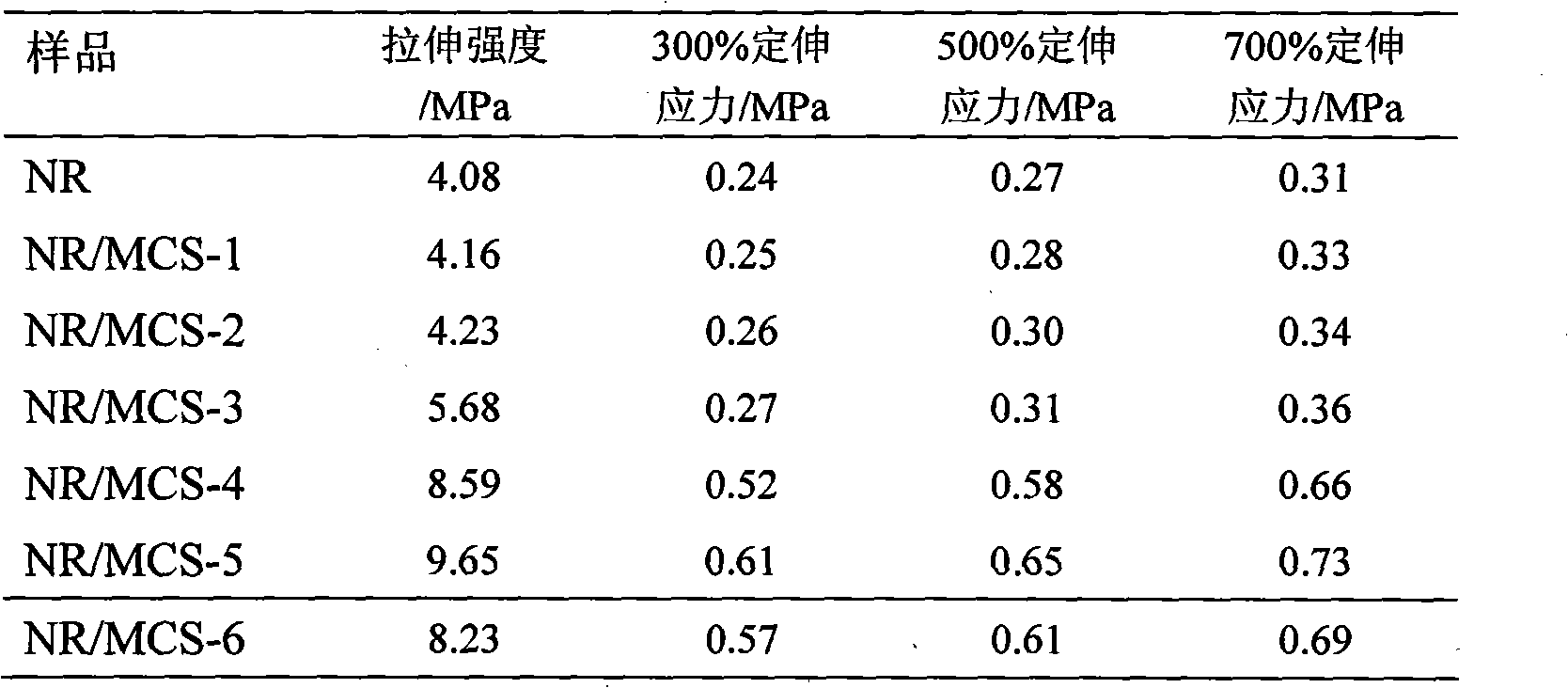

A technology of maleic anhydride acylated chitosan and acid anhydride acylated chitosan salt, applied in the field of chemical modification of natural polymers, can solve the problem that NR does not have antibacterial function and physiological activity, hydrophilicity and heat resistance Poor, no functional side groups and other problems, to achieve the effect of improved antibacterial performance, good antibacterial performance, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Weigh 3 parts of chitosan, add 300 parts of water, stir magnetically, alternately add 0.5 parts of maleic anhydride and 0.5 parts of sodium carbonate every half an hour, repeat 4 times, react at room temperature for 6 hours, sodium hydroxide The pH value of the solution is adjusted to be alkaline, the unreacted chitosan is removed by filtration, and the reaction solution is dialyzed to remove small molecular impurities to prepare the MCS-Na salt solution.

[0046]Add 1 part of non-ionic surfactant Pingping plus "O" to the concentrated natural rubber latex with a dry rubber content of 100 parts to keep the latex stable; weigh 50 mL of a solution containing 20 parts of MCS-Na salt, adjust the pH value to 8, Add it dropwise to natural rubber latex under magnetic stirring conditions, then add 0.5 part of benzoyl peroxide, 0.1 part of N, N-methylenebisacrylamide, stop for 24 hours, add 0.01 part of tetraethylenepentamine, Raising the temperature to 80° C., and reacting for 2...

example 2

[0048] Dissolve 6 parts of maleic anhydride in 100 parts of DMF, add 3 parts of chitosan, N 2 Under protection, the temperature was raised to 130° C. for 2 hours, and the reaction liquid was poured into an ice-water mixture, precipitated, filtered with suction, washed several times with ether, and dried in vacuum to prepare maleic anhydride acylated chitosan (MCS); the obtained MCS is reacted with calcium hydroxide solution to prepare MCS-Ga solution.

[0049] Add 5 parts of non-ionic surfactant flat plus "O" to the concentrated natural rubber latex with dry rubber content of 100 parts to keep the latex stable; weigh 50 mL of the solution containing 30 parts of MCS-Ga, adjust the pH value to 9, and Add it dropwise to the natural rubber latex under the condition of magnetic stirring, then add 0.01 part of tert-butyl hydroperoxide, stop for 24 hours, add 0.3 part of tetraethylenepentamine, raise the temperature to 80°C, react for 10 hours, and make milk Maleic anhydride acylate...

example 3

[0051] Take by weighing 2 parts of chitosan, add 120mL of 2% (mass fraction) acetic acid solution, dissolve under stirring for 1 hour to form a homogeneous solution; take by weighing 4 parts of maleic anhydride, dissolve it in 5mL of acetone, stir Added into the reactor at room temperature for 12 hours, the product was extracted and purified with acetone, and then dried in vacuum to prepare maleic anhydride acylated chitosan (MCS); take 50 mL of the solution containing 1.0 parts of MCS, and add 0.5 parts of ZnO , Preparation of maleic anhydride acylated chitosan zinc solution.

[0052] Add 3 parts of nonionic surfactant Pingping plus "O" to the concentrated natural rubber latex with dry rubber content of 100 parts to keep the latex stable; weigh 50 mL of the solution containing 1 part of MCS-Zn, adjust the pH value to 12, and Add it dropwise to the natural rubber latex under the condition of magnetic stirring, then add 0.8 parts of cumene hydroperoxide, stop for 24 hours, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com