Novel metal ceramic composite material and preparation method thereof

A composite material and cermet technology, which is applied in the field of cermet composite materials, can solve the problems affecting the efficiency of ilmenite utilization, the industrialization process of ilmenite, the low degree of comprehensive utilization of iron, and the intractability of waste acid mother liquor. Comprehensive mechanical properties, excellent wear resistance, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

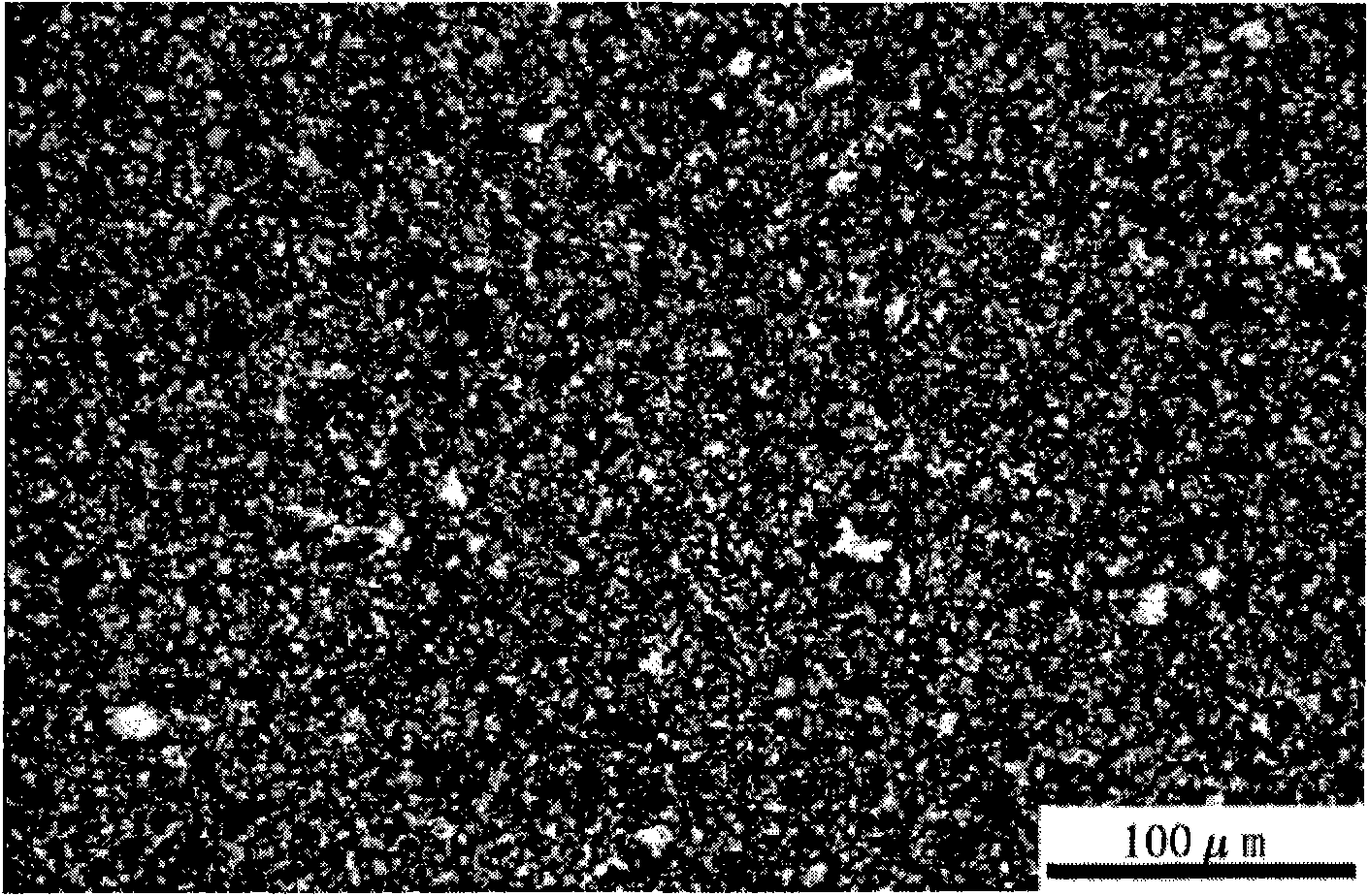

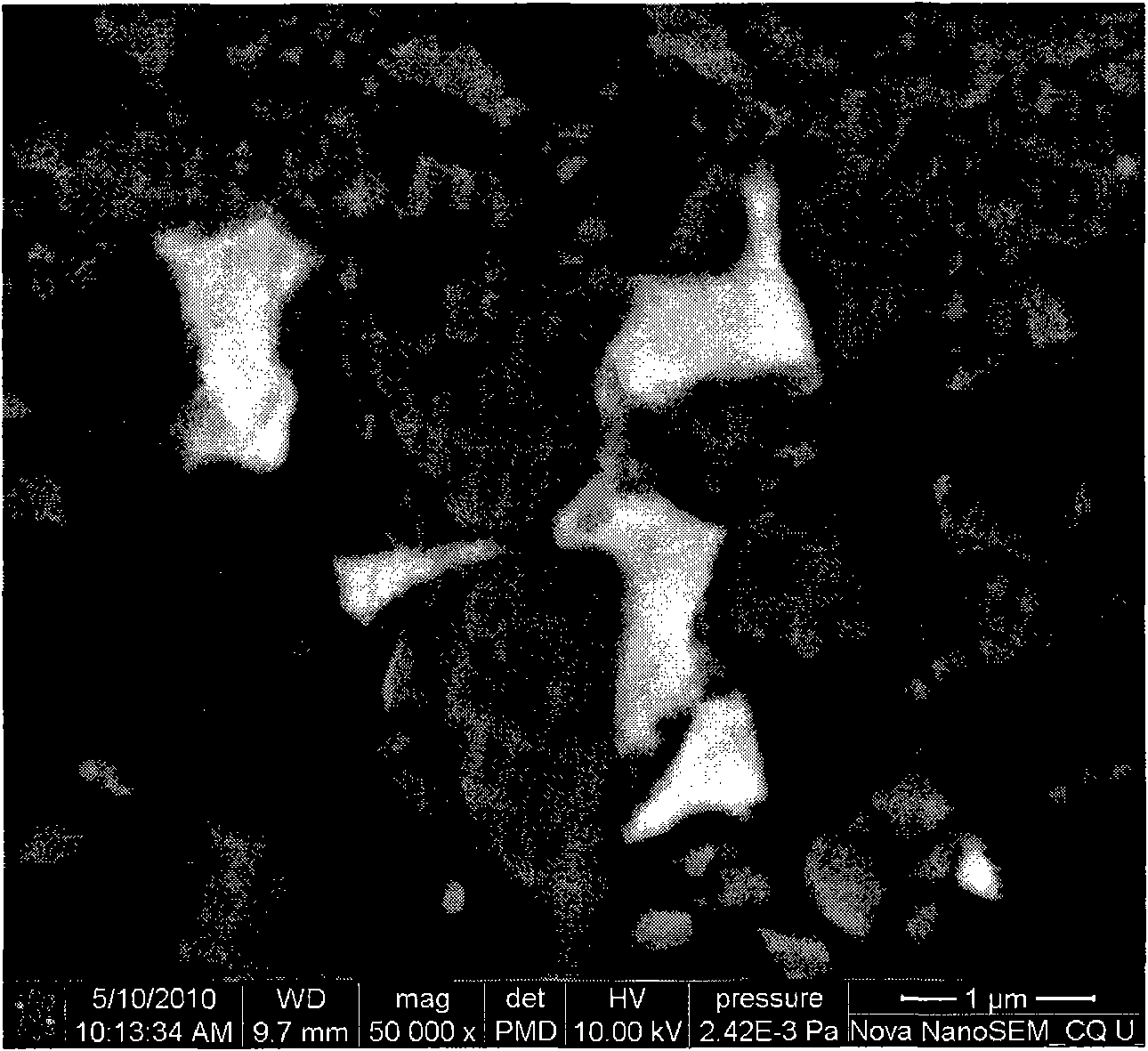

Image

Examples

Embodiment 1

[0023] A kind of preparation technology of metal-ceramic composite material, its concrete steps are as follows:

[0024] (1) Weigh 49.91 grams of ilmenite powder, 17.72 grams of aluminum powder and 3.94 grams of graphite according to the molar ratio of FeTiO3+2Al+C+0Fe on an electronic balance.

[0025] (2) Pour the mixed powder into a ball mill tank with a ball-to-material ratio of 12:1, and ball mill for 4 hours; then, put the ball-milled powder into a desiccator for drying.

[0026] (3) Put the mixture into a hot-pressed graphite mold, put it into a hot-pressed furnace, and pass nitrogen protection after vacuuming.

[0027] (4) Pre-press the powder once during the heating process, and then pressurize 21Mpa when it reaches 1400°C.

[0028] (5) Hold at 1400° C. for 30 minutes under pressure of 21 MPa, and finally cool to obtain metal-ceramic composite material A.

[0029] (6) The mechanical properties of the obtained composite material A are shown in Table 1, and the chemic...

Embodiment 2

[0031] A method for preparing a metal-ceramic composite material is prepared by ball milling technology and hot pressing technology, and the steps are as follows:

[0032] (1) The raw materials are ilmenite powder, aluminum powder, graphite and iron powder. Weigh 39.71 grams of ilmenite powder, 14.11 grams of aluminum powder, 3.13 grams of graphite and 14.63 grams of iron powder on an electronic balance according to the molar ratio of FeTiO3+2Al+C+1Fe.

[0033] (2) Pour the mixed powder into a ball mill jar with a ball-to-material ratio of 12:1, mill for 4 hours, and then put the ball-milled powder into a dryer for drying.

[0034] (3) Put the mixed material into a hot-pressed graphite mold, put it into a hot-pressed furnace, and ventilate nitrogen protection after vacuumizing;

[0035] (4) Pre-press the powder once during the heating process, and then pressurize 21MPa when it reaches 1200°C;

[0036] (5) Hold at 1200° C. under pressure of 21 MPa for 30 minutes, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com