High-impedance high-heat conduction PBT composite material

A composite material, high thermal conductivity technology, applied in the field of functional materials, can solve the problems of reducing the mechanical properties of materials, decreasing the volume resistivity, limited application scope of materials, etc., to achieve the effect of excellent mechanical properties and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

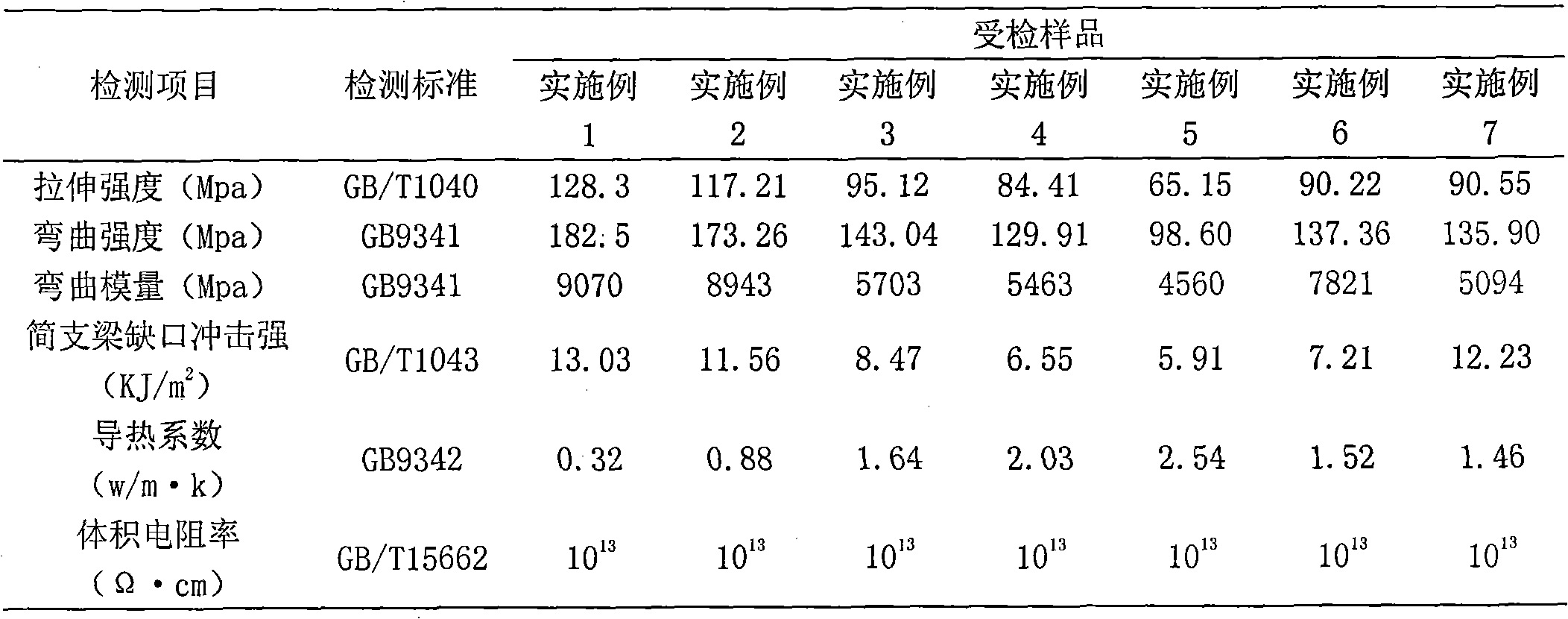

Examples

Embodiment 1

[0023] The high resistance and high thermal conductivity PBT composite material contains the following parts by weight:

[0024] 55 copies of PBT;

[0025] 0.4 parts of antioxidant, consisting of 0.1 part of phenolic antioxidant 2246, 0.3 part of phosphite antioxidant 168;

[0026] 10 parts of surface-active modified aluminum nitride;

[0027] 5 parts of tougheners, composed of polypropylene grafted maleic anhydride;

[0028] 30 parts of reinforcing material, composed of alkali-free glass fiber.

[0029] The modification methods of surface active modified aluminum nitride include:

[0030] Mix dry aluminum nitride and 0.3% aluminum nitride stearic acid at 100°C evenly, then add 1.0% aluminum nitride acrylic acid, stir at 120°C for 15 minutes, continue to stir and cool to room temperature.

Embodiment 2

[0032] The high resistance and high thermal conductivity PBT composite material contains the following parts by weight:

[0033] 32 copies of PBT;

[0034] 0.2 part of antioxidant, composed of hindered phenol antioxidant 1010;

[0035] 30 parts of surface-active modified aluminum nitride;

[0036] 8 parts of tougheners, composed of polypropylene grafted maleic anhydride;

[0037] Reinforcement material, consisting of alkali-free glass fibers.

[0038] Mix dry aluminum nitride and sodium stearate with a mass of 0.7% of aluminum nitride at 115°C, then add acrylic acid with a mass of 0.3% of aluminum nitride, stir at 115°C for 15 minutes, continue to stir and cool to room temperature to obtain .

Embodiment 3

[0040] The high resistance and high thermal conductivity PBT composite material contains the following parts by weight:

[0041] 32 copies of PBT;

[0042] 0.4 part of antioxidant, made up of 0.2 part of phenolic antioxidant 264 (BHT), 0.2 part of phosphite antioxidant 626;

[0043] 40 parts of surface-active modified aluminum nitride;

[0044] 8 parts of tougheners, composed of ethylene elastomer grafted maleic anhydride;

[0045] 20 parts of reinforcing material, composed of alkali-free glass fiber.

[0046] Mix dry aluminum nitride and stearic acid with a mass of 0.5% of aluminum nitride at 95°C, then add butyl acrylate with a mass of 0.3% of aluminum nitride, stir at 120°C for 13 minutes, continue to stir and cool to room temperature to obtain .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com