Special paint for external thermal insulation system of outer wall

A technology for external wall insulation and coatings, which is applied in the direction of coatings, etc., can solve the problems of cracking of the coating finish layer, no thermal insulation effect, and affect the decorative effect, etc., to achieve not easy to stain dust, good crack resistance, and good thermal insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

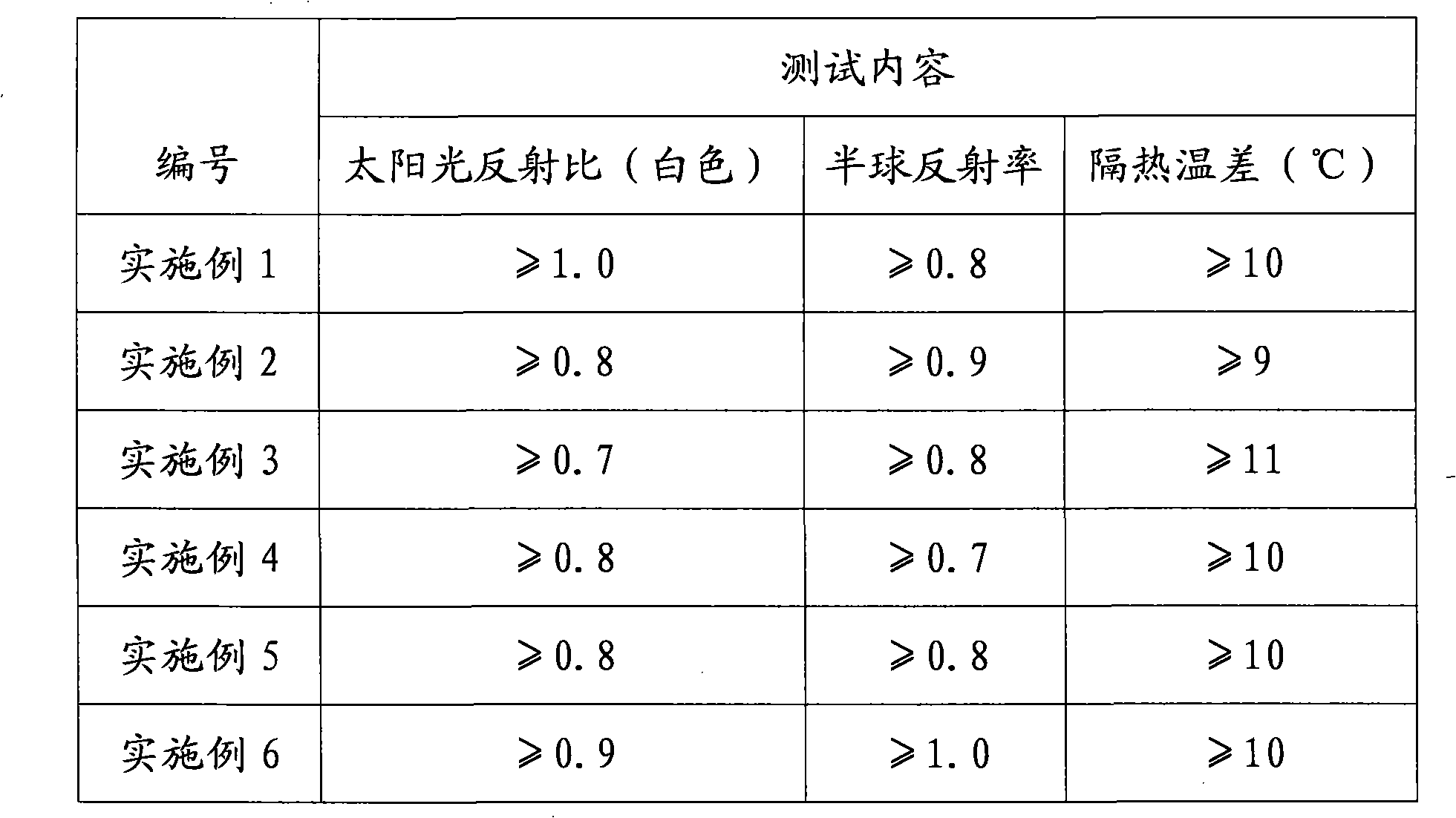

Examples

Embodiment 1

[0025] (1) The parts by weight are 100 parts of water, 1 part of carboxyethyl cellulose, 1 part of 1,2-benzisothiazolin-3-one, 1 part of 5040 dispersant, 5 parts of 5027 dispersant, alkoxy 2 parts of base ethanol, 2 parts of metal soap type defoamer, after mixing, put them into the reaction kettle at one time, add sodium bicarbonate dropwise, and adjust the pH to 6;

[0026] (2) The parts by weight are 10 parts of propylene glycol, 6 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 150 parts of titanium dioxide, 25 parts of calcined kaolin, 800 parts of silica fume Put 45 parts of stone powder, 60 parts of natural barium sulfate powder, 2 parts of metal soap type defoamer, 200 parts of silicon acrylic emulsion, 100 parts of elastic pure acrylic emulsion, and 1 part of polysaccharide polymeric thickener into the above reaction solution to react together. Obtain light yellow milky substance;

[0027] (3) Add 60 parts by weight of glass microbead powder to the above-men...

Embodiment 2

[0029] (1) The parts by weight are 200 parts of water, 1 part of carboxyethyl cellulose, 1.5 parts of 2-methyl-4-isothiazolin-3-one, 2 parts of 5040 dispersant, 6 parts of 5027 dispersant, poly 2 parts of the mixture of siloxane-polyether copolymer and polyether-modified organosilicon compound, 2 parts of organosilicon defoamer, after mixing, put them into the reaction kettle at one time, add sodium bicarbonate dropwise, and adjust the pH to 7;

[0030] (2) The parts by weight are 10 parts of propylene glycol, 8 parts of propylene glycol phenyl ether, 175 parts of titanium dioxide, 25 parts of calcined kaolin, 50 parts of 800 wollastonite powder, 60 parts of natural barium sulfate powder, and 2 parts of organic silicon defoamer , 250 parts of silicon acrylic emulsion, 130 parts of elastic pure acrylic emulsion, 2 parts of polyurethane polymer compound aqueous solution thickener are put into above-mentioned reaction liquid and react together, obtain pale yellow emulsion;

[003...

Embodiment 3

[0033] (1) The parts by weight are 300 parts of water, 2 parts of carboxyethyl cellulose, 2 parts of 5-chloro-2-methyl-4-isothiazolin-3-one, 3 parts of 5040 dispersant, 3 parts of 5027 dispersant 7 parts, 3 parts of octylphenol polyoxyethylene ether, 4 parts of mineral oil defoamer, after mixing, put them into the reaction kettle at one time, add sodium bicarbonate dropwise, and adjust the pH to 8;

[0034] (2) parts by weight are 15 parts of propylene glycol, 10 parts of propylene glycol butyl ether, 200 parts of titanium dioxide, 30 parts of calcined kaolin, 60 parts of 800 wollastonite powder, 80 parts of natural barium sulfate powder, 4 parts of mineral oil defoamer, 300 parts of silicon-acrylic emulsion, 200 parts of elastic pure acrylic emulsion, and 3 parts of non-ionic associative polyurethane thickener are put into the above reaction solution to react together to obtain a milky white emulsion;

[0035] (3) Add 80 parts by weight of glass microbead powder to the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com