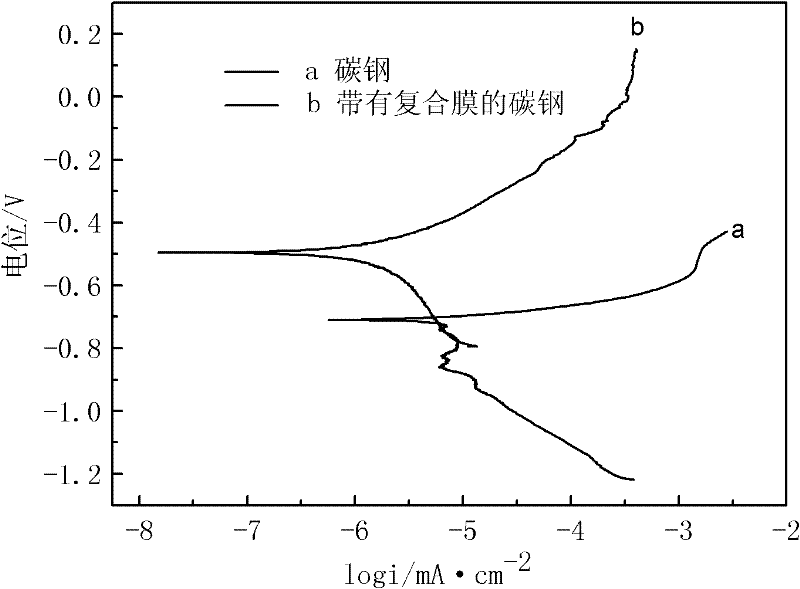

Method for preparing NiP/TiO2 anticorrosion composite film on surface of carbon steel

A technology of composite film and carbon steel, applied in the direction of surface reaction electrolytic coating, photographic technology, liquid chemical plating, etc., can solve the problems of difficult recycling, limited doping space of titanium dioxide nanotubes, affecting promotion and use, etc., to achieve The effect of enhancing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) take water as solvent configuration plating solution A, wherein nickel sulfate is 10g / L, sodium hypophosphite is 15g / L, complexing agent lactic acid is 10ml / L, and buffer sodium acetate is 5g / L;

[0024] (2) adjust the pH value of plating solution A to be 3, then heat plating solution A to 70°C and carry out electroless plating on carbon steel for 30 minutes to obtain carbon steel coated with NiP;

[0025] (3) configure plating solution B: configure the aqueous solution of citric acid earlier, and the concentration is 20g / L; then the aqueous solution of described citric acid and TiCl 3 Solution (analytical grade) mixed, the aqueous solution of citric acid and TiCl 3 The volume ratio of the solution is 3: 1; Finally, the pH value of the mixed solution is adjusted to 2 with sodium hydroxide;

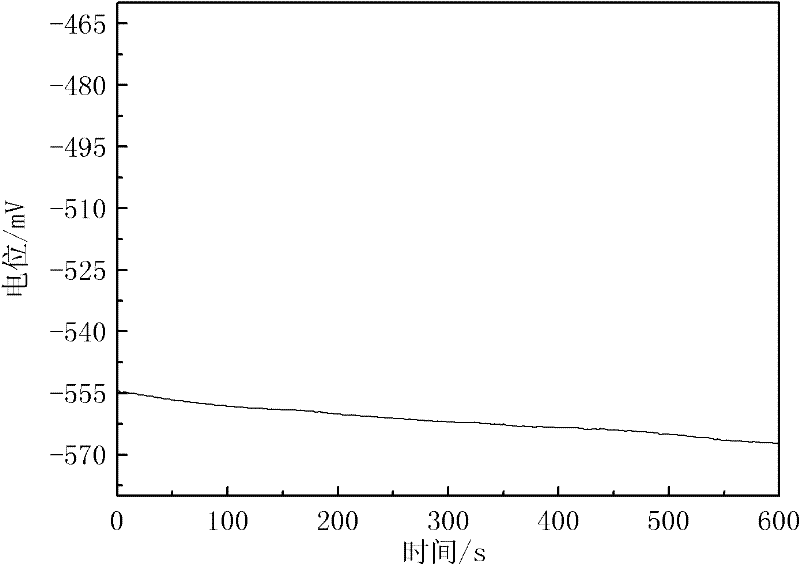

[0026] (4) Using a three-electrode system for anodic electrodeposition to obtain NiP / TiO 2 Corrosion-resistant composite film. Among them, the carbon steel coated with NiP wa...

Embodiment 2

[0028] (1) take water as solvent configuration plating solution A, wherein nickel sulfate is 20g / L, sodium hypophosphite is 20g / L, complexing agent lactic acid is 5ml / L, and buffering agent sodium fluoride is 3g / L;

[0029] (2) adjust the pH value of plating solution A to be 4.5, then heat plating solution A to 65°C and carry out electroless plating on carbon steel for 1 hour to obtain carbon steel coated with NiP;

[0030] (3) configure plating solution B: configure the aqueous solution of citric acid earlier, and the concentration is 25g / L; then the aqueous solution of described citric acid and TiCl3 Solution (analytical grade) mixed, the aqueous solution of citric acid and TiCl 3 The volume ratio of the solution is 1: 2; Finally, the pH value of the mixed solution is adjusted to 3 with sodium bicarbonate;

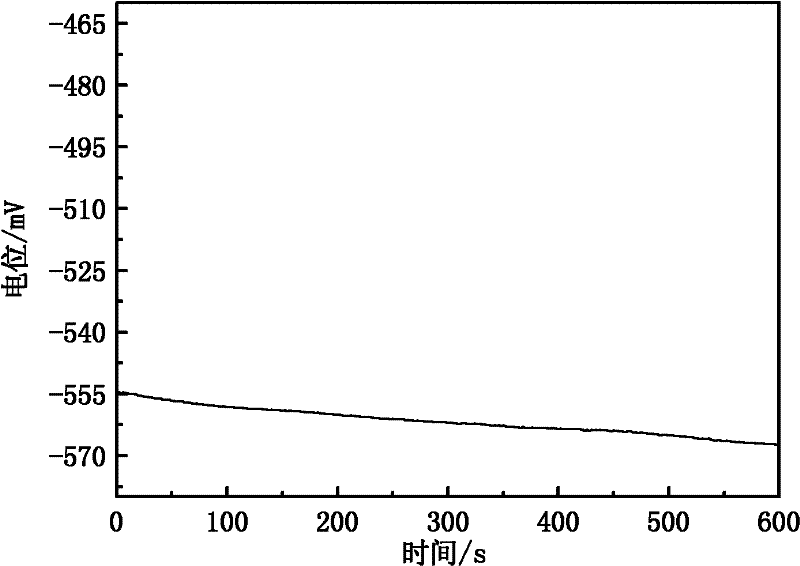

[0031] (4) Using a three-electrode system for anodic electrodeposition to obtain NiP / TiO 2 Corrosion-resistant composite film. Among them, the carbon steel coated with...

Embodiment 3

[0033] (1) take water as solvent configuration plating solution A, wherein nickel nitrate is 10g / L, sodium hypophosphite is 20g / L, complexing agent lactic acid is 10ml / L, buffer potassium fluoride is 5g / L;

[0034] (2) adjust the pH value of plating solution A to be 4, then heat plating solution A to 67 ℃ to carry out chemical plating on carbon steel, the time is 0.5 hour, obtain the carbon steel coated with NiP;

[0035] (3) configure plating solution B: configure the aqueous solution of citric acid earlier, and the concentration is 20g / L; then the aqueous solution of described citric acid and TiCl 3 solution (chemically pure) mixed, the aqueous solution of citric acid and TiCl 3 The volume ratio of the solution is 3: 2; Finally, the pH value of the mixed solution is adjusted to 3 with sodium bicarbonate;

[0036] (4) Using a three-electrode system for anodic electrodeposition to obtain NiP / TiO 2 Corrosion-resistant composite film. Among them, the carbon steel coated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com