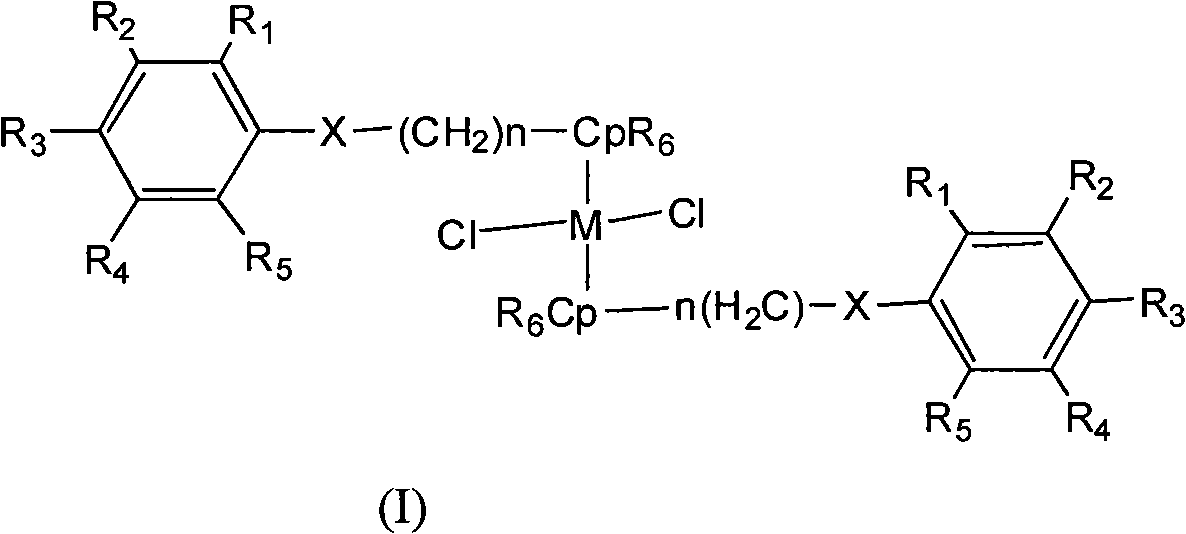

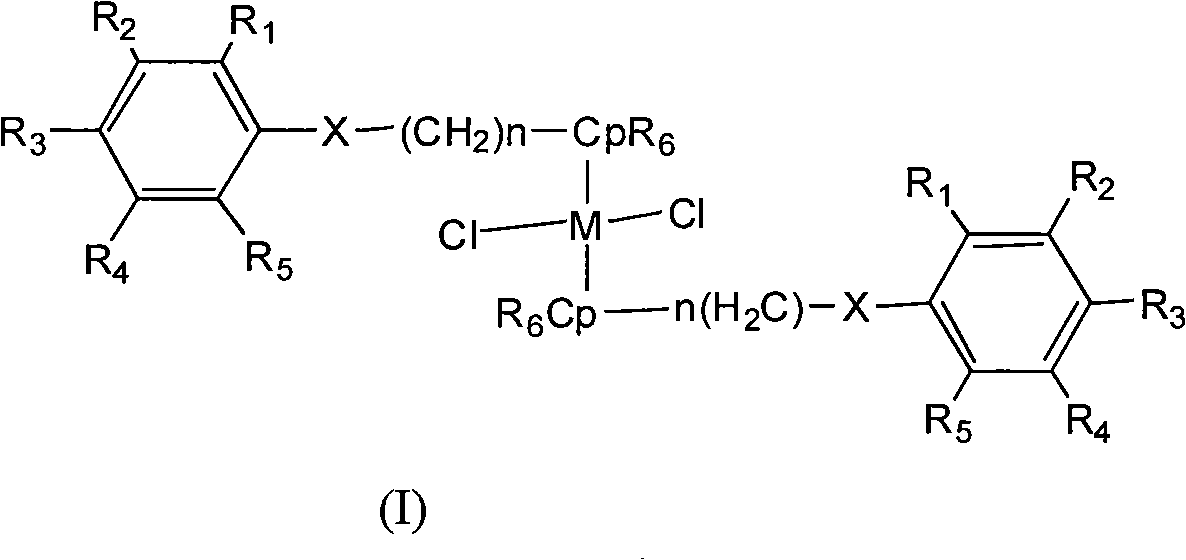

Load type metallocene catalyst as well as preparation method and application thereof

A technology of metallocene catalyst and metallocene compound, applied in the field of catalyst science, can solve the problems such as difficult to support catalyst, consumption of MAO, complicated preparation, etc., and achieve the effect of overcoming sticking kettle phenomenon, simple preparation and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of supported metallocene catalyst, comprising the following steps:

[0032] (1) Preparation of ligand: 1-bromo-5-(4-methylphenoxy)pentane [p-CH 3 C 6 h 4 O(CH 2 ) 5 Br]

[0033] Under an ice-water bath, 10.8 g (0.1 mol) of p-cresol was added to 100 mL of methanol solution containing 4.4 g (0.1 mol) of sodium hydroxide, and stirred for 30 minutes to obtain a reddish methanol solution of sodium p-cresate. Under stirring, the solution was added dropwise to 1.0 mol α, ω-dibromopentane, heated to reflux, and the gas phase followed the reaction for about 5 hours. After the reaction, the solvent methanol was recovered by atmospheric distillation, the residual liquid was cooled to room temperature, 30 mL of distilled water was added, the liquid was separated, the organic phase was washed twice with 20 mL of distilled water, dried with anhydrous magnesium sulfate, the solvent and raw materials were recovered by rotary evaporation, and 123 -126°C (2mmHg...

Embodiment 2

[0040] A preparation method of supported metallocene catalyst, comprising the following steps:

[0041] (1) Preparation of ligand: same as Example 1;

[0042] (2) Preparation of main catalyst: heteroatom metallocene compound [p-CH 3 C 6 h 4 O(CH 2 ) 5 Ind] 2 ZrCl 2 (B)

[0043] The preparation method is the same as in Example 1, except that the sodium cyclopentadiene is changed to indenyllithium to obtain 1.69g of complex B with a yield of 51.2%. 42 h 46 Cl 2 o 2 Zr: Calculated: C, 67.72%, H, 6.22%, found, C, 67.65%, H, 6.31%.

[0044] (3) Supported metallocene catalyst S-B catalyzes ethylene polymerization

[0045] Take 3.0 mg of the main catalyst B prepared in step (2) and dissolve it in 10 mL of dry toluene, then slowly add 1.5 mol / L of 1 mL of methylaluminoxane toluene solution, after the addition is completed, react at 40 ° C for 2 h, and then add to In the toluene suspension containing 0.03g dry clay, stir and mix for 0.5h. Then add the mixed solution into ...

Embodiment 4

[0054] (1) Preparation of ligand: same as Example 3;

[0055] Heteroatom metallocene compounds [p-CH 3 C 6 h 4 O(CH 2 ) 6 Ind] 2 ZrCl 2 (D)

[0056] (2) Preparation of main catalyst: preparation method is the same as embodiment 1 step (2), adopting the 1-bromo-6-(4-methylphenoxy) hexane that step (1) makes in embodiment 3 is raw material , changing the cyclopentadienyl sodium into indenyl lithium to obtain 2.04g of complex C with a yield of 56.1%, C 44 h 50 Cl 2 o 2 Zr: Calculated: C, 68.37%, H, 6.52%, found, C, 68.25%, H, 6.61%.

[0057] (3) Supported metallocene catalyst S-D catalyzed ethylene polymerization

[0058] Dissolve 6 mg of complex D in 10 mL of dry toluene, then slowly add 1.5 mol / L of 1 mL of methylalumoxane toluene solution, after the addition is complete, react at 40°C for 2 h, then add to toluene containing 0.05 g of dry clay to suspend solution, stirred and mixed for 0.5h. Then add the mixed solution into a 2L high-pressure stainless steel stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com