Surface plasma resonance sensor chip and preparation method thereof

A surface plasmon and resonance sensor technology, applied in ion implantation plating, coating, metal material coating process, etc., can solve the problems of cumbersome operation, poor selectivity, low sensitivity, etc., and achieve simple operation steps and controllable thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

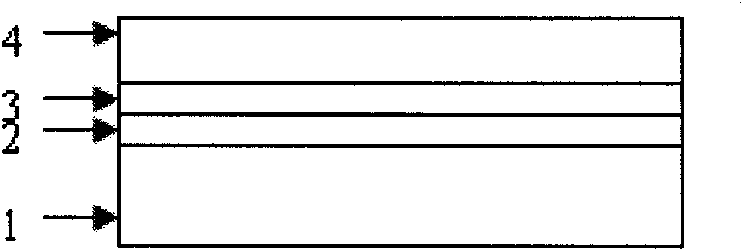

[0043] A surface plasmon resonance sensor chip, such as figure 1 As shown, it includes a glass substrate 1, a gold film layer 2, a monomolecular alkyl chain layer 3 and a molecularly imprinted polymer film 4; Base chain layer 3 and molecularly imprinted polymer film 4;

[0044] The structural formula of the monomolecular alkyl chain layer 3 is Au-(CH 2 ) 11 CH 3 ;

[0045] The molecularly imprinted polymer film 4 is obtained by photopolymerization of template molecules, functional monomers, crosslinking agents, pore forming agents and photoinitiators, the template molecule is the target molecule testosterone to be imprinted, and the functional monomer is methacrylic acid The crosslinking agent is ethylene glycol dimethacrylate; the pore forming agent is acetonitrile;

[0046] A method for preparing a surface plasmon resonance sensor chip, the specific steps of which are:

[0047] 1) The method of vacuum evaporation is used to plate a gold film layer 2 on the glass substr...

Embodiment 2

[0057] A surface plasmon resonance sensor chip, such as figure 1 As shown, it includes a glass substrate 1, a gold film layer 2, a monomolecular alkyl chain layer 3 and a molecularly imprinted polymer film 4; Base chain layer 3 and molecularly imprinted polymer film 4;

[0058]The structural formula of the monomolecular alkyl chain layer 3 is Au-(CH 2 ) 11 CH 3 ;

[0059] The molecularly imprinted polymer film 4 is obtained by photopolymerization of template molecules, functional monomers, crosslinking agents, pore forming agents and photoinitiators, the template molecule is the target molecule testosterone to be imprinted, and the functional monomer is methacrylic acid The crosslinking agent is ethylene glycol dimethacrylate; the pore forming agent is acetonitrile;

[0060] A method for preparing a surface plasmon resonance sensor chip, the specific steps of which are:

[0061] 1) with 1) in embodiment 1;

[0062] 2) with 2) in embodiment 1;

[0063] 3) with 3) in emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com