Cartilage derived collagen sponge scaffold and preparation method thereof

A technology of collagen sponge and cartilage, applied in the field of biomedical materials, can solve the problems of inhomogeneous cartilage scaffold materials, inconsistent repairing defect effects, difficult industrial standardized production, etc., and achieve the effect of favorable adhesion, good repairing effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

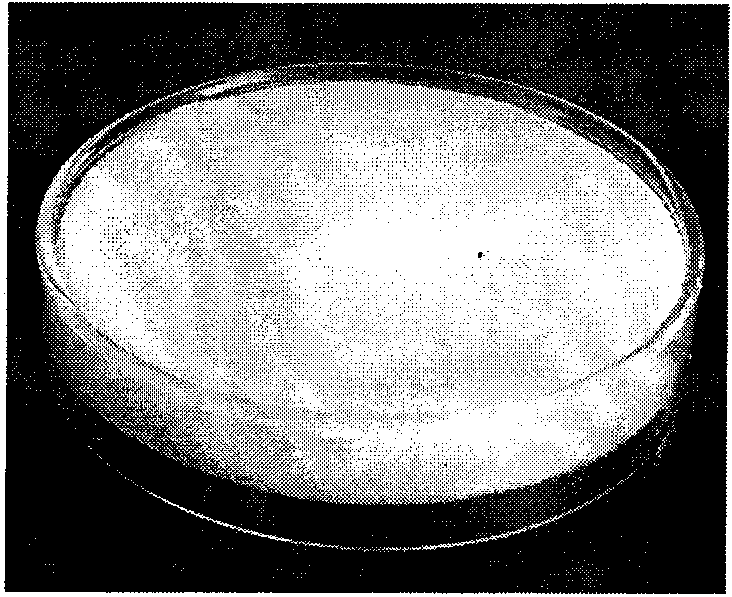

[0051] Embodiment 1: Preparation of cartilage-derived collagen sponge scaffold of the present invention

[0052] 1. Take fresh pig ear cartilage and pre-freeze it in a refrigerator at -70°C, freeze-dry it in a vacuum freeze dryer for 24 hours, grind it with a liquid nitrogen freezer pulverizer for 30 minutes, and take cartilage particles with a particle size of 90 μm or less through a No. 8 sieve;

[0053] 2. Mix cartilage microparticles with trypsin EDTA mixture (0.25% Trypsin+0.1% EDTA, TNE) according to volume ratio V / V 1:8~1:12, shake at 4°C for 12~30hr, centrifuge at 1000g for 10min and discard. After washing with PBS repeatedly for 3 times, the supernatant was discarded by centrifugation;

[0054] 3. Mix cartilage microparticles with 0.5mol / L HAc at a volume ratio of 1:10, add pepsin (wet weight ratio of pepsin and cartilage microparticles is 2:100), and continuously stir at 4°C for 12-24 hours.

[0055] 4. Centrifuge at 110g for 5min, take the supernatant, adjust the p...

Embodiment 2

[0064] Embodiment 2: Preparation of cartilage-derived collagen sponge scaffold of the present invention

[0065] 1. Take fresh pork rib cartilage and pre-freeze it in a -70°C refrigerator, freeze-dry it in a vacuum freeze dryer for 24 hours, grind it with a liquid nitrogen freezer for 30 minutes, and take cartilage particles with a particle size of 90 μm or less through a No. 8 sieve;

[0066] 2. Mix cartilage microparticles with trypsin EDTA mixture (0.25% Trypsin+0.1% EDTA, TNE) according to volume ratio V / V 1:8~1:12, shake at 4°C for 12~30hr, centrifuge at 1000g for 10min and discard. After washing with PBS repeatedly for 3 times, the supernatant was discarded by centrifugation;

[0067] 3. Mix the cartilage microparticles with 0.5 mol / L HAc at a volume ratio of 1:5, and add pepsin (the wet weight ratio of pepsin to cartilage microparticles is 3:100). Stirring was continued at 4°C for 24 hr.

[0068] 4. Centrifuge at 110g for 5min, take the supernatant, adjust the pH valu...

Embodiment 3

[0072] Embodiment 3: Preparation of cartilage-derived collagen sponge scaffold of the present invention

[0073] 1. Take fresh bovine ear cartilage and pre-freeze it in a refrigerator at -70°C, freeze-dry it in a vacuum freeze dryer for 24 hours, grind it with a liquid nitrogen freezer pulverizer for 30 minutes, and take cartilage particles with a particle size of 90 μm or less through a No. 8 sieve;

[0074] 2. Mix cartilage microparticles with trypsin EDTA mixture (0.25% Trypsin+0.1% EDTA, TNE) according to volume ratio V / V 1:8~1:12, shake at 4°C for 12~30hr, centrifuge at 1000g for 10min and discard. After washing with PBS repeatedly for 3 times, the supernatant was discarded by centrifugation;

[0075] 3. Mix the cartilage microparticles with 0.5 mol / L HAc at a volume ratio of 1:10, and add pepsin (wet weight ratio of pepsin to cartilage microparticles is 1:100). Stirring was continued at 4°C for 24 hr.

[0076] 4. Centrifuge at 110g for 5min, take the supernatant, adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com