Low energy consumption integrated hydrolysis-denitrifying ammoxidation process for treating low C/N ratio wastewater

A technology of denitrifying ammonia oxidation and low carbon to nitrogen ratio, applied in the field of environmental engineering, can solve the problems of insufficient flexibility and difficult control, and achieve the effect of improving the removal effect, reducing the complexity of the control and reducing the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

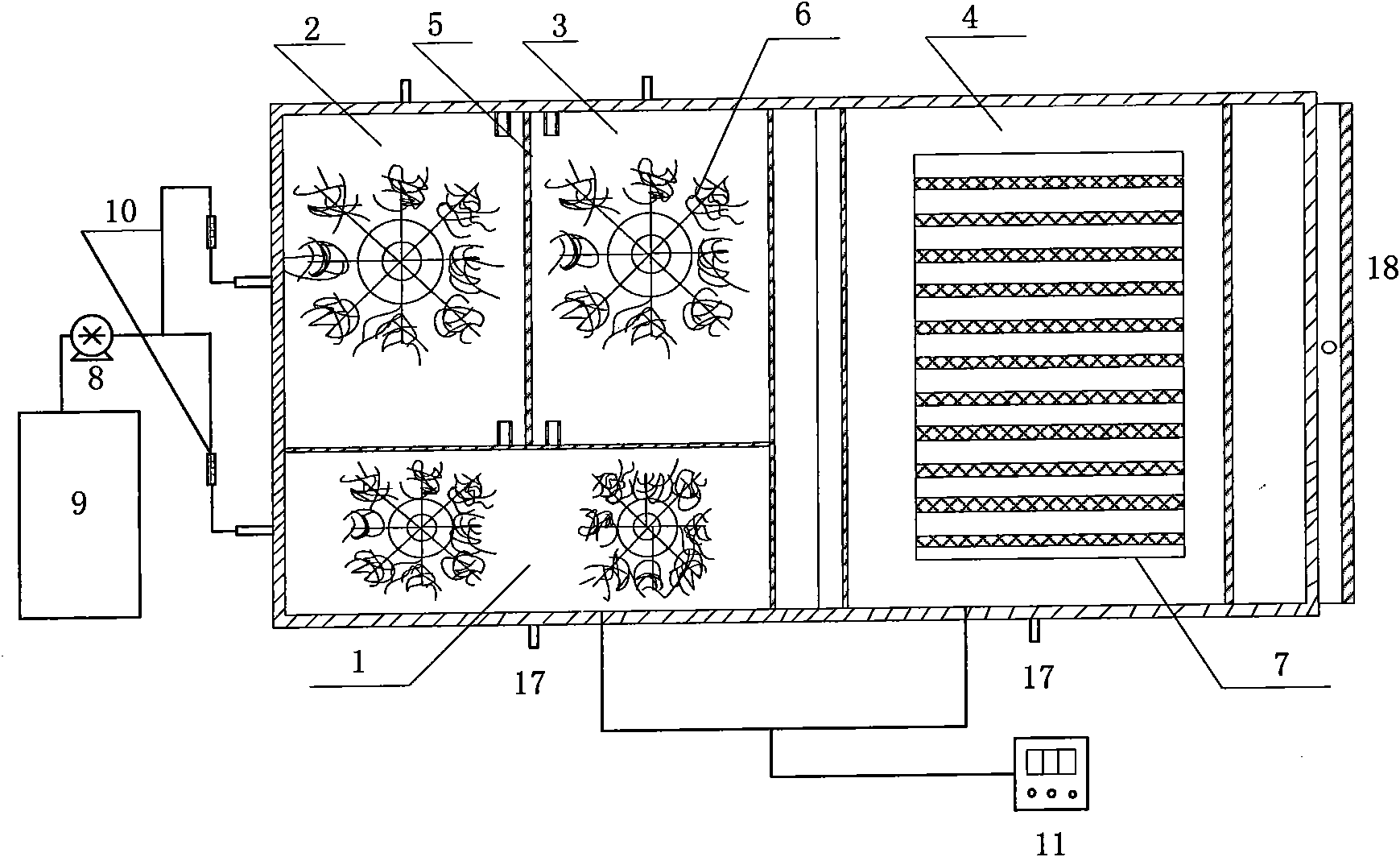

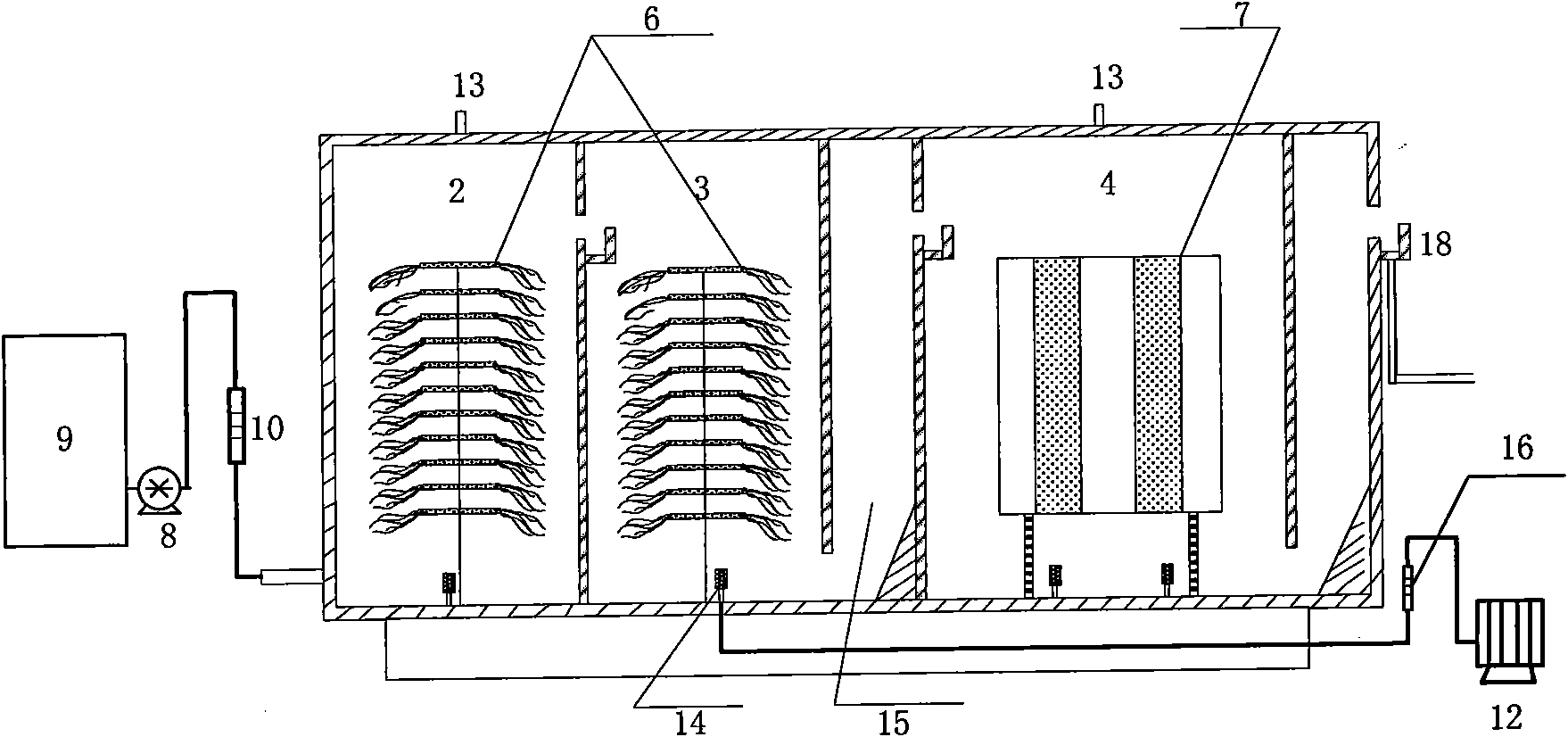

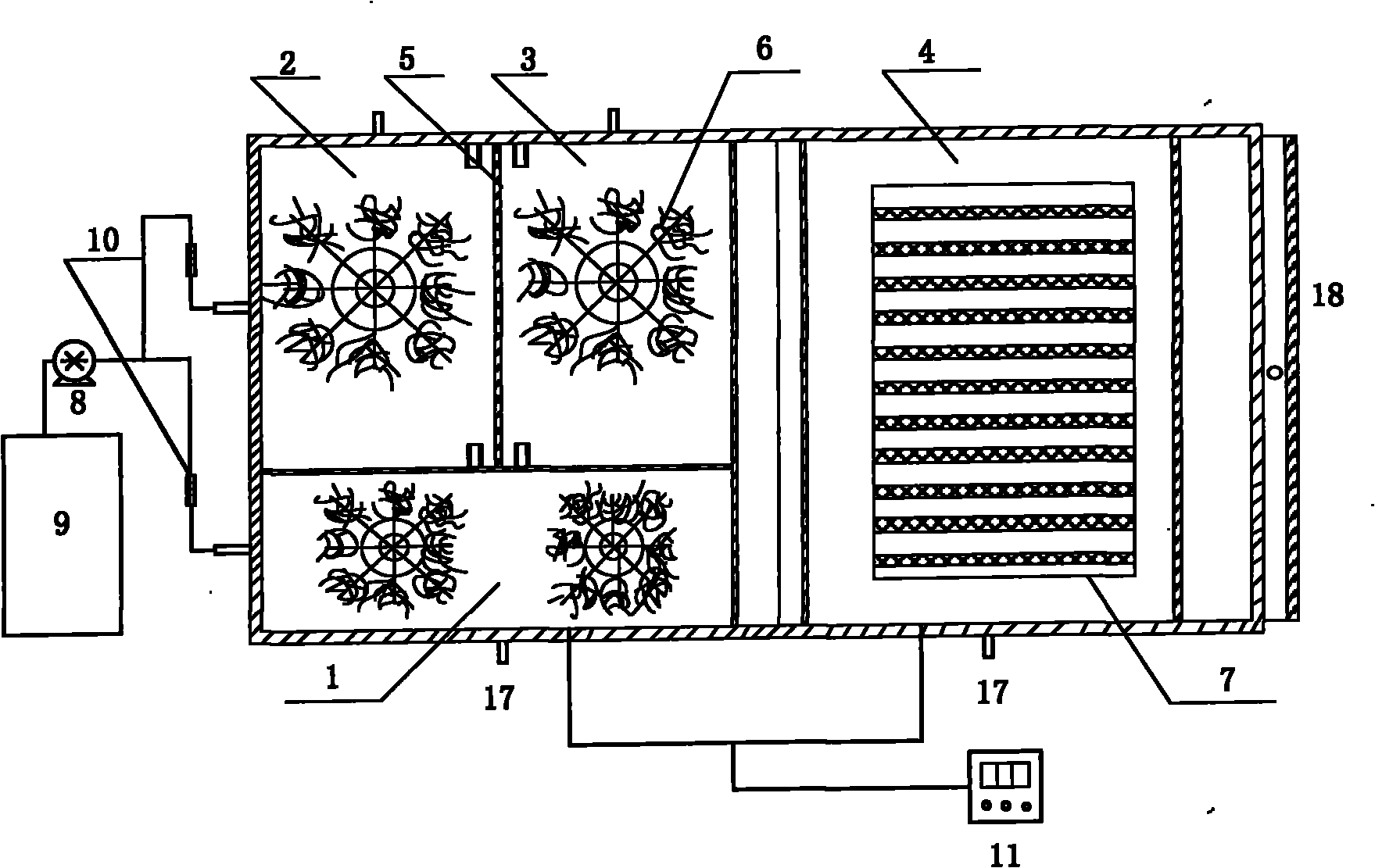

[0014] The best embodiment of the device of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0015] The process can be used to treat low-COD and high-ammonia-nitrogen urban domestic sewage with a C / N ratio of about 2-4. If the influent water quality changes, when the C / N ratio is higher than 4, the hydraulic retention time of the hydrolysis section should be appropriately increased according to the COD value; when the C / N ratio is low, the hydraulic retention time of the denitrification ammonium oxidation reaction section should be appropriately extended. The reactor is fed by a peristaltic pump 8, and the volume of sewage entering the second hydrolysis zone 1 and the first hydrolysis zone 2 is controlled by a liquid flow meter 10 (the display ratio of the two flow meters is set at about 1). 2 The anaerobic hydrolysis reaction in hydrolysis zone 1 removes most of the COD and produces a moderate amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com