Method for preparing electronic grade hydrogenated trimellitic anhydride

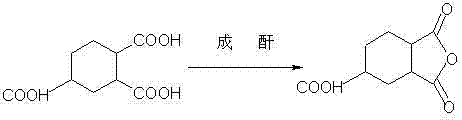

A technology for trimellitic anhydride and trimellitic acid, which is applied in the field of preparation of electronic grade hydrogenated trimellitic anhydride, can solve the problems of low purity of hydrogenated trimellitic anhydride and cannot meet electronic grade requirements, etc., achieves purity and metal ion content to help, reduces production costs, and improves conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0019] The preparation method of the electronic grade hydrogenated trimellitic anhydride of the present embodiment has the following steps:

[0020] ① Hydrolysis of acid anhydride into acid reaction. Add 35g of commercially available trimellitic anhydride (standard GB / T 23967-2009 "Industrial Trimellitic anhydride", trimellitic anhydride content is 95wt%) and 350mL of deionized water into a 500mL three-necked bottle, and reflux to generate trimellitic acid , reflux reaction for 4 hours, then cooled to ambient temperature (25°C in this example), white crystals precipitated, filtered, decolorized and refined the filter cake with activated carbon to obtain 37g of white trimellitic acid, the yield was 96.7%, The purity by GC analysis was 99.6%.

[0021] ② Catalytic hydrogenation reaction. In the autoclave of 500mL, add the 37g trimellitic acid that step ① makes, add simultaneously the mixed solvent that is made up of the ethanol of 120mL and the deionized water of 120mL and the ...

Embodiment 2~ Embodiment 5)

[0024] The steps of each embodiment 1. are the same as Example 1, the difference is that step 2. catalytic hydrogenation reaction and step 3. dehydration into anhydride reaction, the specific differences of catalytic hydrogenation reaction are shown in Table 1, dehydration into anhydride reaction See Table 2 for specific differences.

[0025] Table 1

[0026] Example 1 Example 2 Example 3 Example 4 Example 5 mixed solvent 120mL of ethanol and 120mL of deionized water 120mL methanol and 120mL deionized water 120mL THF and 120mL deionized water 120mL DMF and 120mL deionized water 120 mL of isopropanol and 120 mL of deionized water noble metal catalyst 3.5g of 5wt% Pd-C catalyst 2.0g of 10wt% Rh-C catalyst 3.5g of 5wt% Ru-C catalyst 1.0g of 5wt% Pt-C catalyst 3.0g of 10wt% Rh-C catalyst hydrogen pressure 2 MPa 3 MPa 4MPa 2 MPa 1 MPa temperature 80℃~85℃ 60℃~65℃ 95℃~100℃ 40℃~65℃ 75℃~80℃ time 3h 4h 7h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com