Multifunctional ZnO whisker reinforced stator rubber for screw pump

A screw pump, multi-functional technology, applied in the field of multi-functional ZnO whisker reinforced screw pump stator rubber, can solve the problems of low rubber strength, insufficient wear resistance and chemical stability, poor plasticity, etc. The effect of improving the service life and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0008] Example 1: Reinforced rubber formulation and preparation process

[0009] The mastication of nitrile rubber is different from that of general-purpose rubber. It requires low temperature, small roller distance, and low-capacity thin pass method, so as to effectively obtain a certain degree of plasticity. Under normal temperature conditions, masticate the nitrile rubber raw rubber on the open mill for about 10 minutes until it is covered with rolls. The temperature of the roll is 45-55°C. Note that the temperature of the front roll of the double-roller plastic mixer must be higher than the temperature of the rear roll by 10°C, and the roll distance is 1mm. Put the masticated nitrile rubber in the air for 2 to 6 hours before kneading. The mixing of nitrile rubber adopts low temperature mixing, and the roller temperature is 40-60°C. First take 65% of nitrile rubber, then add 1% of sulfur powder in turn; 3% of modified nano-zinc oxide; 7% of modified ZnO whiskers; 0.7% of ...

example 2

[0010] Example 2: Modification method of rubber reinforcement additive nanometer

[0011] The multifunctional ZnO whisker reinforced rubber formulation provided by the invention is characterized in that, in the experimental process, a silane coupling agent is used, i.e. two-[Y-(triethoxysilyl) propyl]-tetrasulfide or emulsifier OP-10 That is, the condensation product of alkylphenol and ethylene oxide, the ZnO whisker is modified by spray treatment. The contents involved in the experiment include: surface modification and anti-aggregation mechanism, selection of surfactant and combination of dispersant, etc. The main principles of the design are to reduce the surface energy state of the particles, eliminate the surface charge of the particles, and improve the affinity between the particles and the organic phase.

[0012] The modification steps of ZnO whiskers and nano ZnO are as follows:

[0013] Modification of nano-ZnO: Dry nano-ZnO at 200-210°C for 1.5 hours to make it ful...

example 3

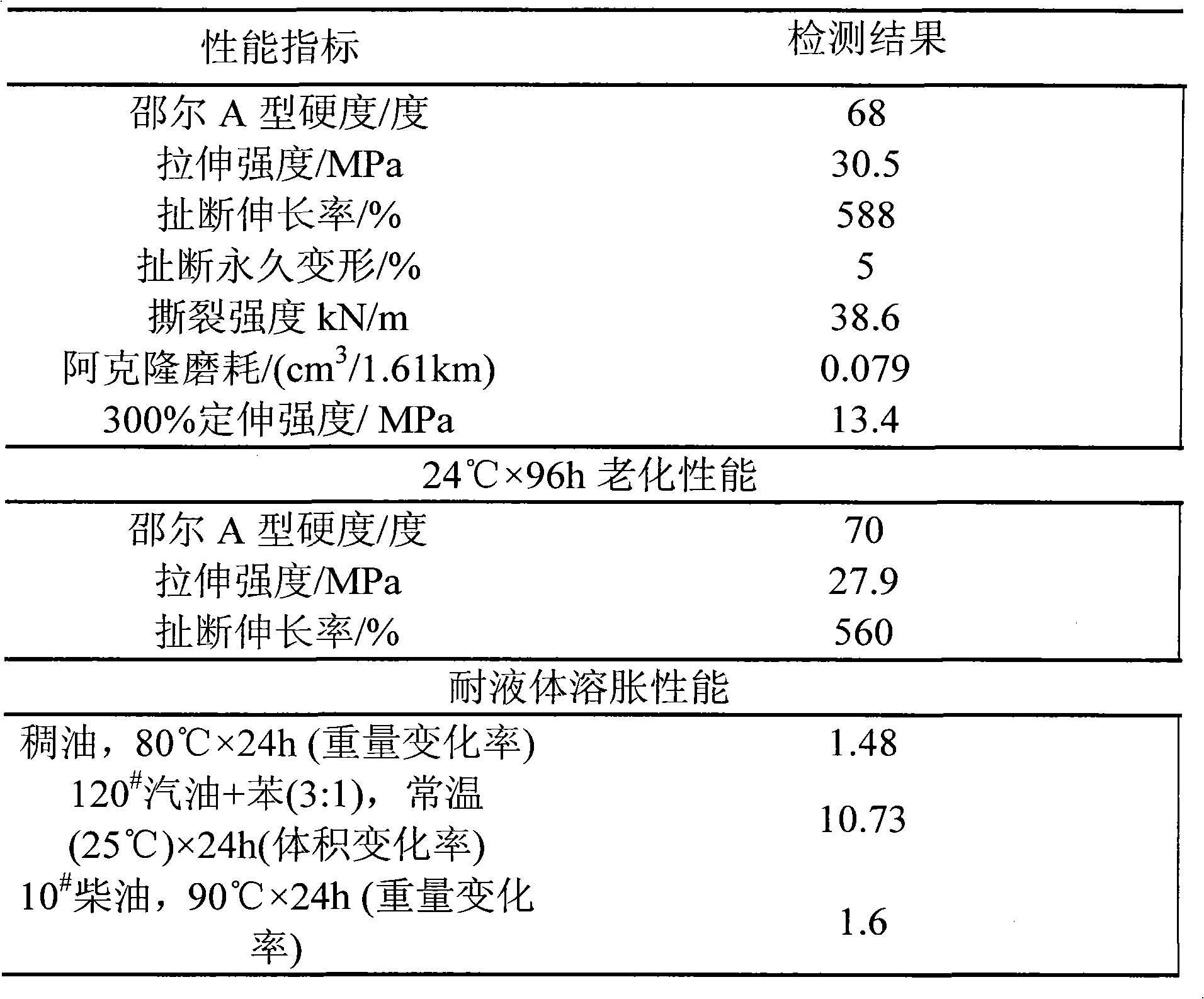

[0015] Example 3: Enhancement effect of ZnO whiskers on NBR

[0016] Since the amount of ZnO whiskers and nano-ZnO is directly related to economic factors, it is impossible to increase the amount indefinitely for industrial production considerations. Therefore, when the additions of ZnO whiskers and nano-ZnO are selected to be 7% and 3% respectively, the above-mentioned The multifunctional ZnO whisker-reinforced rubber formula is characterized in that its comprehensive performance in indoor testing is shown in Table 1.

[0017] Table 1 Reinforcing effect of ZnO whiskers on rubber

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com