Single matrix white light fluorescent powder for white light LED and preparation method thereof

A fluorescent powder and white light technology, applied in the field of fluorescent powder and its preparation, can solve the problems of component segregation, poor color rendering, high energy consumption, etc., and achieve the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

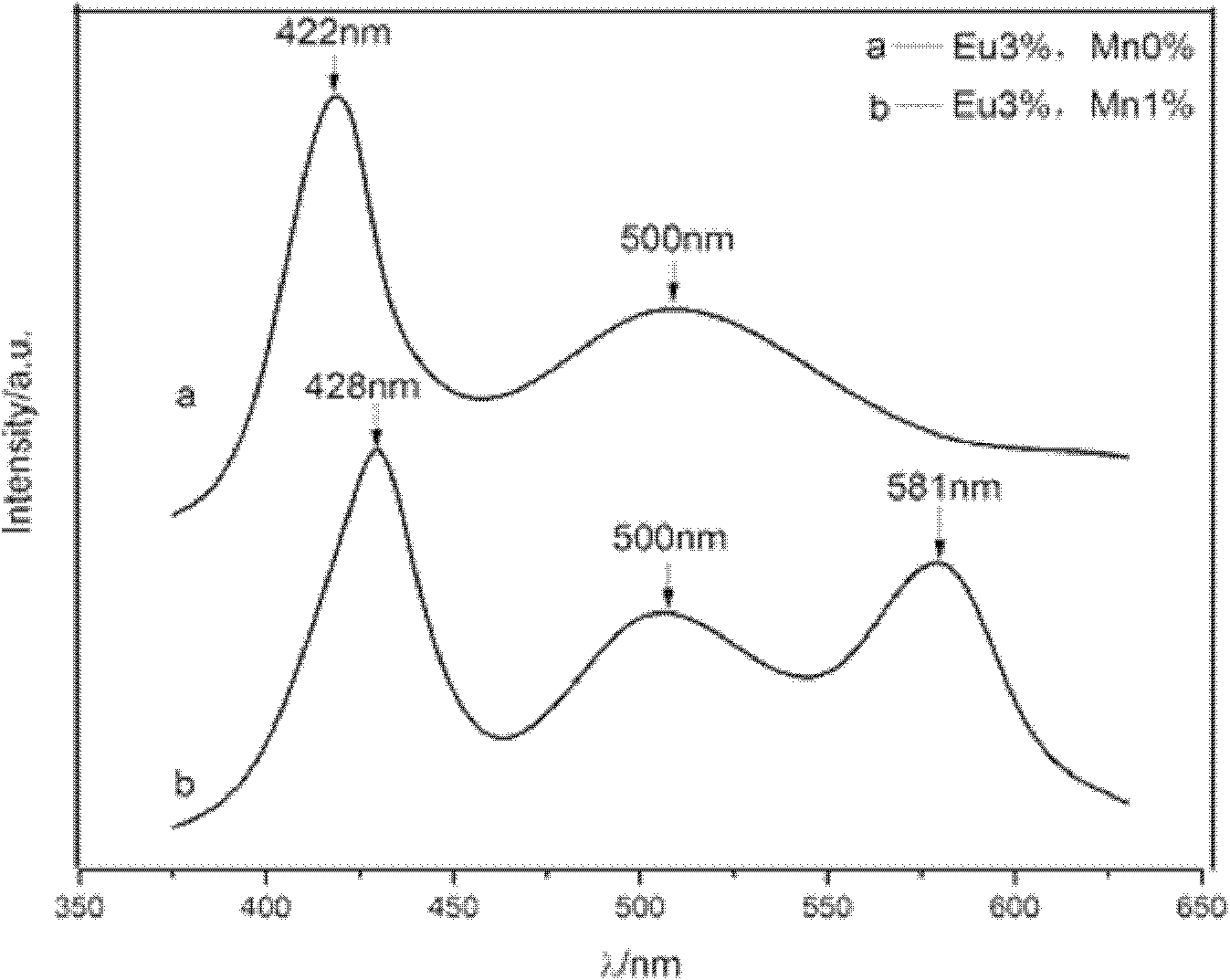

Embodiment 1

[0019] Step 1: According to the chemical composition to Ca 2 SiO 3 Cl 2 :3%Eu 2+ , 1% Mn 2+ , respectively weighed 4.723g calcium nitrate tetrahydrate Ca (NO 3 ) 2 4H 2 O, 2.2198g anhydrous calcium chloride CaCl 2 , 0.1056g europium oxide Eu 2 o 3 , and 0.0502g manganese nitrate tetrahydrate Mn(NO 3 ) 2 4H 2 O, then, measure 4.48ml tetraethyl orthosilicate TEOS (C 8 h 20 o 4 Si);

[0020] Step 2: 1) Dissolve calcium nitrate tetrahydrate and calcium chloride anhydrous weighed in step 1 in 9ml deionized water, and obtain a uniform and transparent solution A containing calcium ions after completely dissolving;

[0021] 2) Europium oxide Eu 2 o 3 Dissolve in nitric acid solution with a concentration of 56-58wt%. Nitric acid is suitable for dissolving europium oxide, and it is prepared as europium nitrate Eu(NO 3 ) 3 Solution B;

[0022] 3) Mix solution B and manganese nitrate tetrahydrate Mn(NO 3 ) 2 4H 2 O is dissolved in solution A together, and after stir...

Embodiment 2

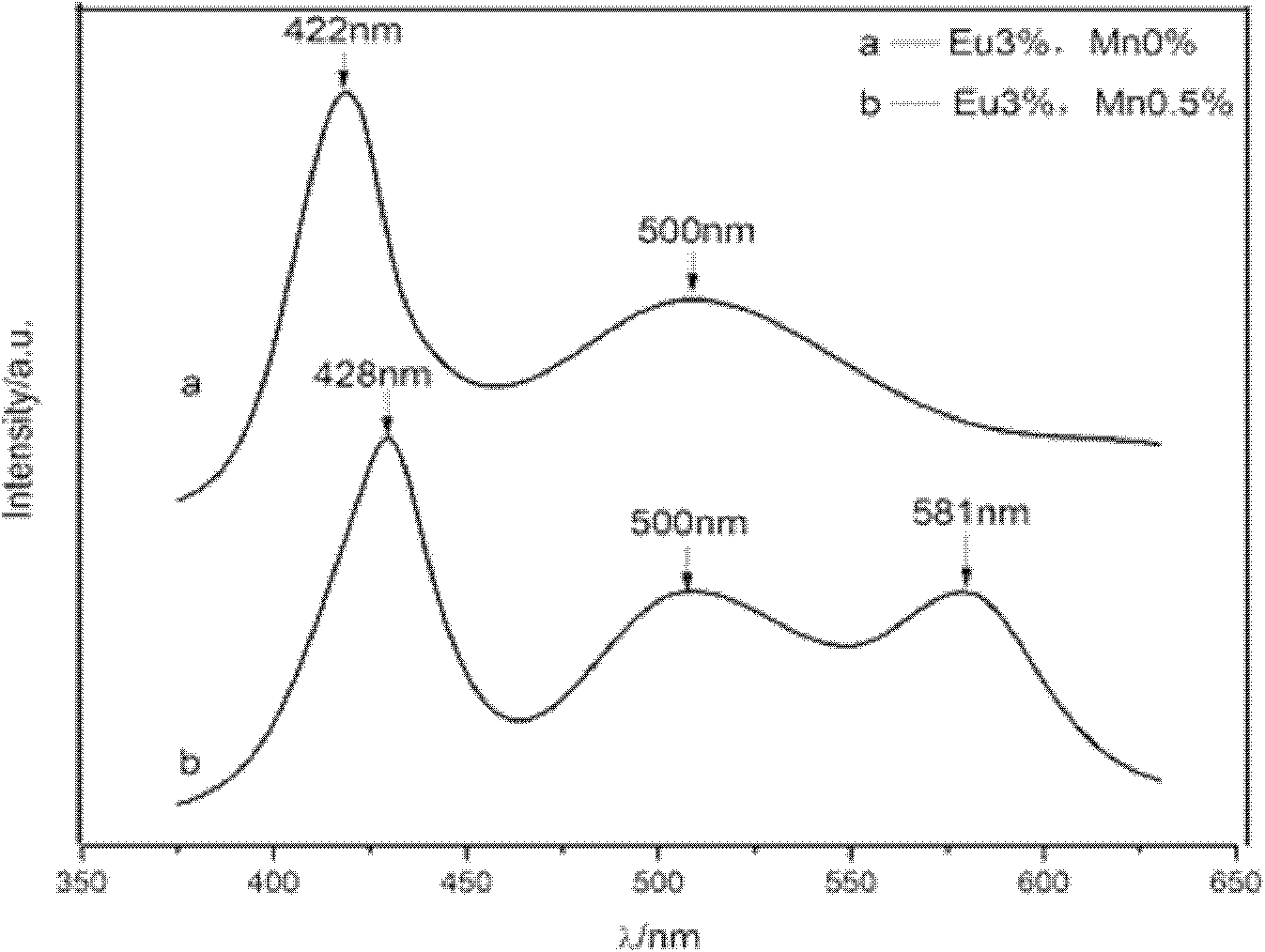

[0027] Step 1: According to the chemical composition to Ca 2 SiO 3 Cl 2 :3%Eu 2+ , 0.5% Mn 2+ , respectively weighed 4.723g calcium nitrate tetrahydrate Ca (NO 3 ) 2 4H 2 O, 2.2198g anhydrous calcium chloride CaCl 2 , 0.1056g europium oxide Eu 2 o 3 , and 0.0251g manganese nitrate tetrahydrate Mn(NO 3 ) 24H 2 O, then, measure 4.48ml tetraethyl orthosilicate TEOS (C 8 h 20 o 4 Si);

[0028] Step 2: 1) Dissolve calcium nitrate tetrahydrate and calcium chloride anhydrous weighed in step 1 in 9ml deionized water, and obtain a uniform and transparent solution A containing calcium ions after completely dissolving;

[0029] 2) Europium oxide Eu 2 o 3 Dissolve in nitric acid solution with a concentration of 56-58wt%. Nitric acid is suitable for dissolving europium oxide, and it is prepared as europium nitrate Eu(NO 3 ) 3 Solution B;

[0030] 3) Mix solution B and manganese nitrate tetrahydrate Mn(NO 3 ) 2 4H 2 O is dissolved in solution A together, and after sti...

Embodiment 3

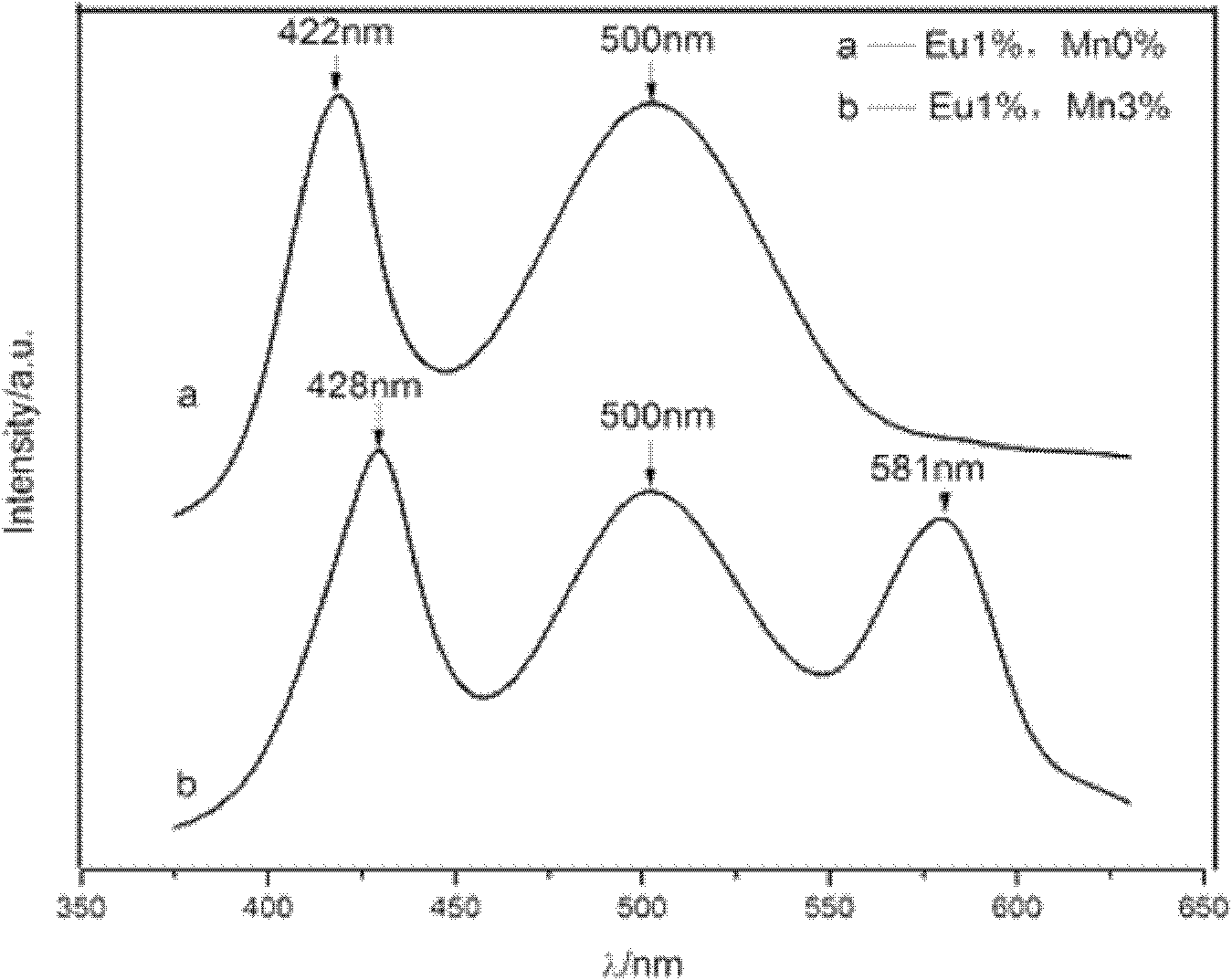

[0035] Step 1: According to the chemical composition to Ca 2 SiO 3 Cl 2 :1%Eu 2+ , 3% Mn 2+ , respectively weighed 4.723g calcium nitrate tetrahydrate Ca (NO 3 ) 2 4H 2 O, 2.2198g anhydrous calcium chloride CaCl 2 , 0.0352g europium oxide Eu 2 o 3 , and 0.1506g manganese nitrate tetrahydrate Mn(NO 3 ) 2 4H 2 O, then, measure 4.48ml tetraethyl orthosilicate TEOS (C 8 h 20 o 4 Si);

[0036] Step 2: 1) Dissolve calcium nitrate tetrahydrate and calcium chloride anhydrous weighed in step 1 in 11ml deionized water, and obtain a uniform and transparent calcium ion-containing solution A after completely dissolving;

[0037] 2) Europium oxide Eu 2 o 3 Dissolve in nitric acid solution with a concentration of 56-58wt%. Nitric acid is suitable for dissolving europium oxide, and it is prepared as europium nitrate Eu(NO 3 ) 3 Solution B;

[0038] 3) Mix solution B and manganese nitrate tetrahydrate Mn(NO 3 ) 2 4H 2 O is dissolved in solution A together, and after stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com