Method for stabilizing activity of alpha-hydroxybutyricdehydrogenaseand lactic dehydrogenase of quality-control serum

A hydroxybutyrate dehydrogenase and lactate dehydrogenase technology, applied in biological testing, material testing and other directions, can solve the problems of high price, short half-life of enzyme molecules, low serum enzyme activity, etc. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

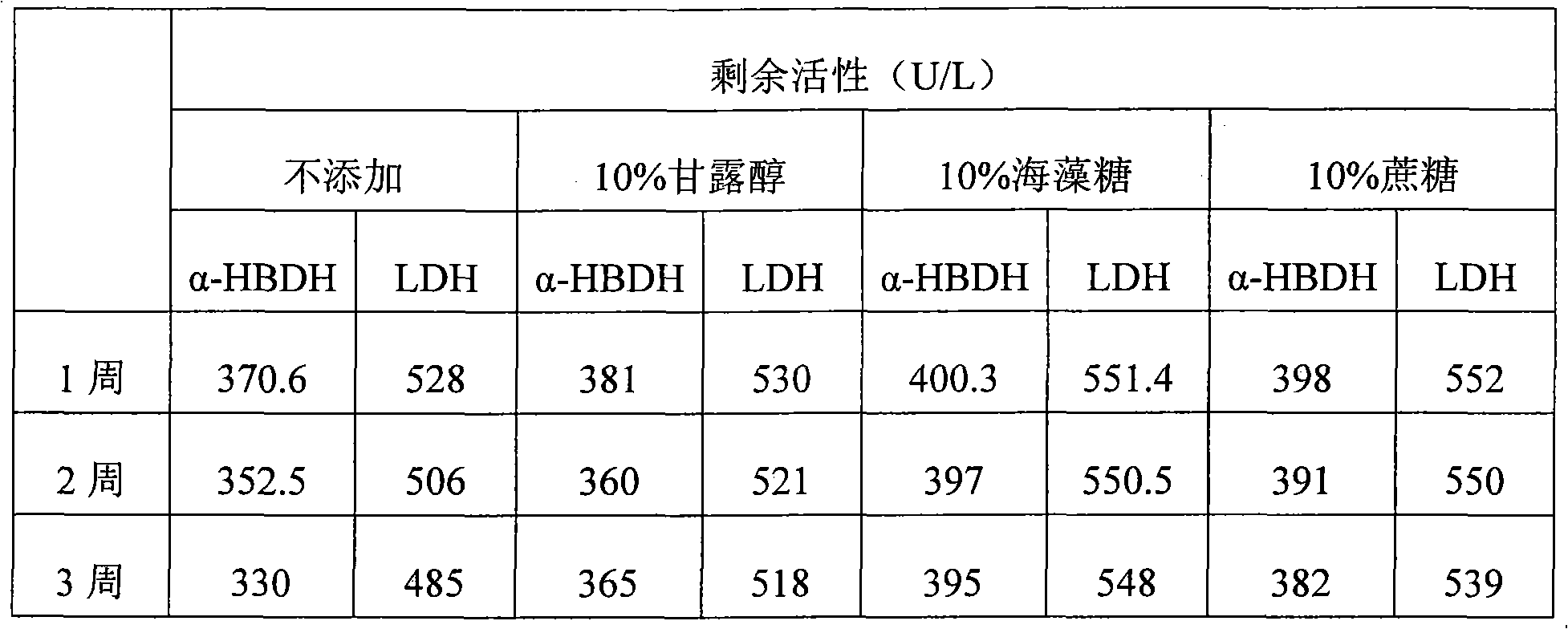

[0033] To the phosphate buffer (pH 7.5, concentration 50mmol / L) containing 3% BSA, 200mM glycine, α-HBDH and LDH concentrations of 400U / L and 550U / L respectively, add according to the following formula:

[0034] Among them: the concentration of phosphate buffer saline, by weighing disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) 6.02g and sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 (0) 0.5g is a benchmark, and the concentration after dissolving and constant volume in distilled water to 1000mL is 50mmol / L;

[0035] (1) No added sugar and sugar alcohol protective agent; (2) 10% mannitol; (3) 10% trehalose; (4) 10% sucrose.

[0036] Take 2 mL of the prepared solution of each group and put it into a brown vial for freeze-drying. Freeze-drying conditions: after vacuuming at a freezing temperature of -50°C, carry out main drying at -20°C for 12 hours, and carry out 24 hours at 25°C. For secondary drying within 1 hour, the lyophilized product was reconstituted with 2 mL of dis...

Embodiment 2

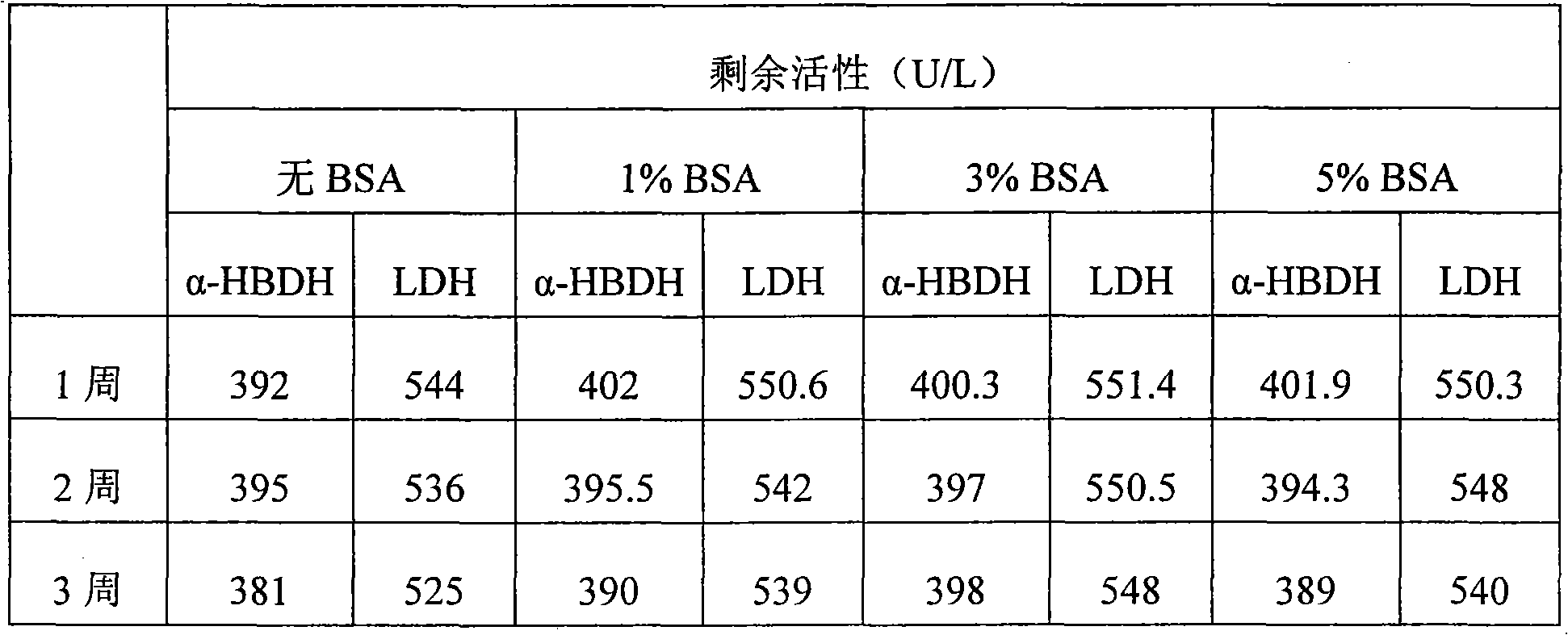

[0041] To the phosphate buffer (pH 7.5, concentration 50mmol / L) containing 10% trehalose, 200mM glycine, α-HBDH and LDH concentrations were respectively 400U / L and 550U / L, wherein: the concentration of phosphate buffer, Disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) 6.02g and sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 (0) 0.5g is a benchmark, and the concentration after dissolving and constant volume in distilled water to 1000mL is 50mmol / L;

[0042]Add respectively according to the following formula: (1) No BSA (2) 1% BSA (2) 3% BSA (3) 5% BSA. Take 2 mL of the prepared solution of each group and put it into a brown vial for freeze-drying. Add 2 mL of distilled water to reconstitute the freeze-dried product and measure the activity of α-HBDH and LDH. Place the reserved freeze-dried product in a 37°C incubation The box was accelerated for 3 weeks and measured once a week. The results are shown in Table 2:

[0043] Table 2

[0044]

[0045] According to the resu...

Embodiment 3

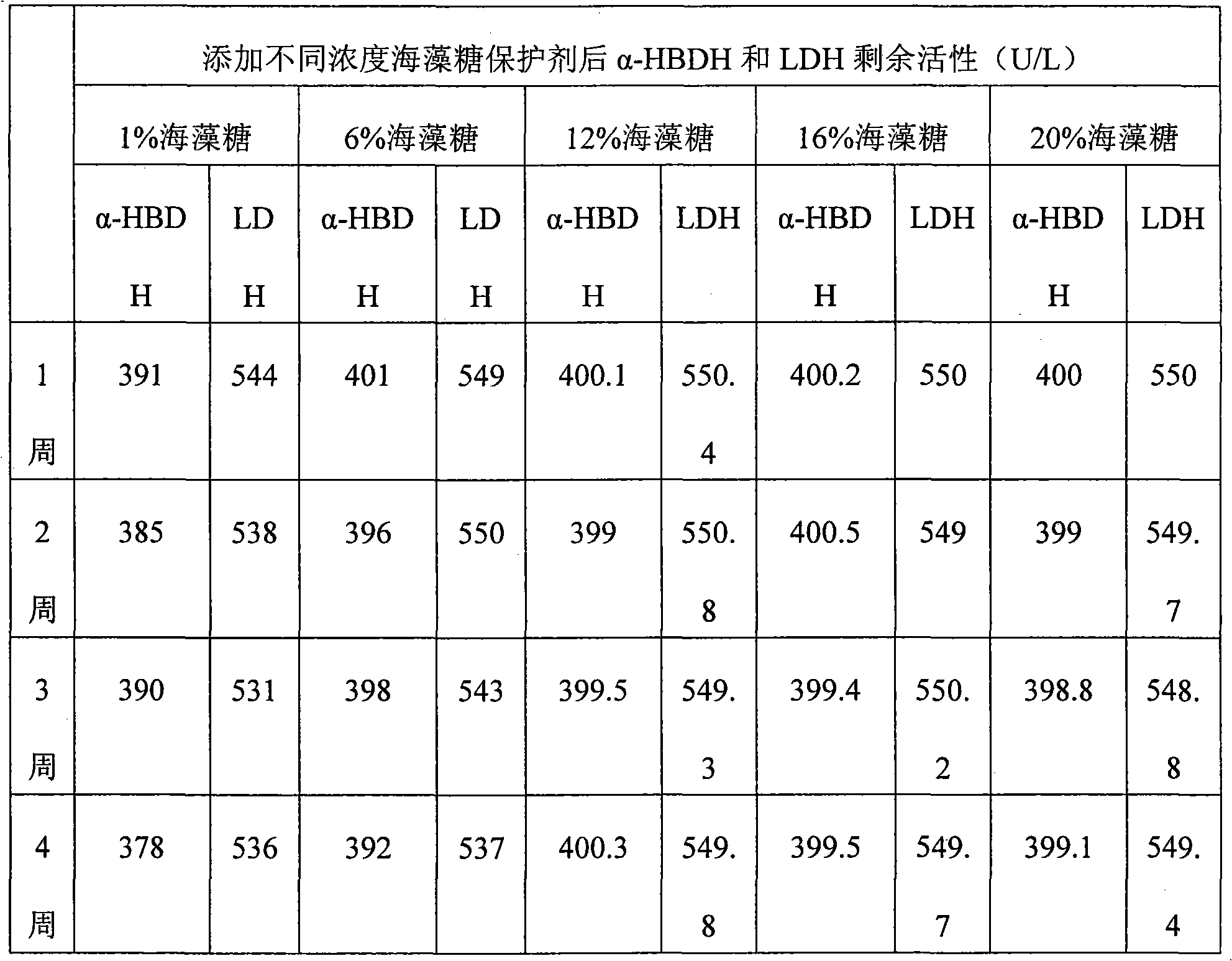

[0047] To the phosphate buffer (pH value 7.5, concentration 50mmol / L) that contains 3%BSA, 200mM glycine, α-HBDH and LDH concentration are respectively 400U / L and 550U / L, wherein: the concentration of phosphate buffer, with Weigh disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) 6.02g and sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 (0) 0.5g is a benchmark, and the concentration after dissolving and constant volume in distilled water to 1000mL is 50mmol / L;

[0048] Add respectively according to the following formula: (1) 1% trehalose (2) 6% trehalose (3) 12% trehalose (4) 16% trehalose (5) 20% trehalose. Take 2 mL of the prepared solution of each group and put it into a brown vial for freeze-drying. Add 2 mL of distilled water to reconstitute the freeze-dried product and measure the activity of α-HBDH and LDH. Place the reserved freeze-dried product in a 37°C incubation The box was accelerated for 4 weeks and measured once a week. The results are shown in Table 3:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com