Polishing pad for chemical mechanical planarization and manufacturing method thereof

A technology of chemical machinery and manufacturing method, which is applied in the direction of manufacturing tools, grinding/polishing equipment, wheels with flexible working parts, etc. It can solve problems such as scratches, over-polishing, and complexity, and achieve stable polishing performance. The effect of good process controllability and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

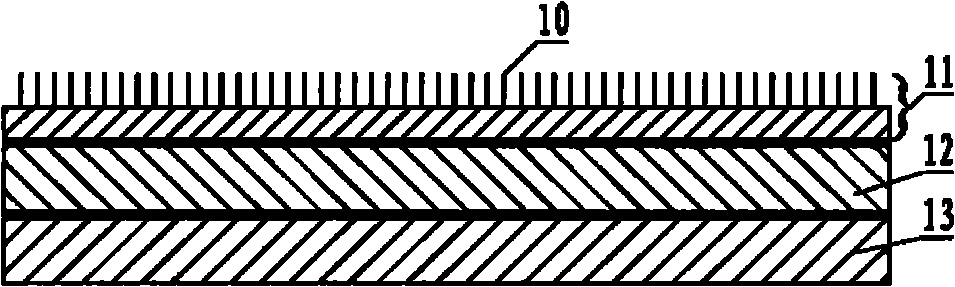

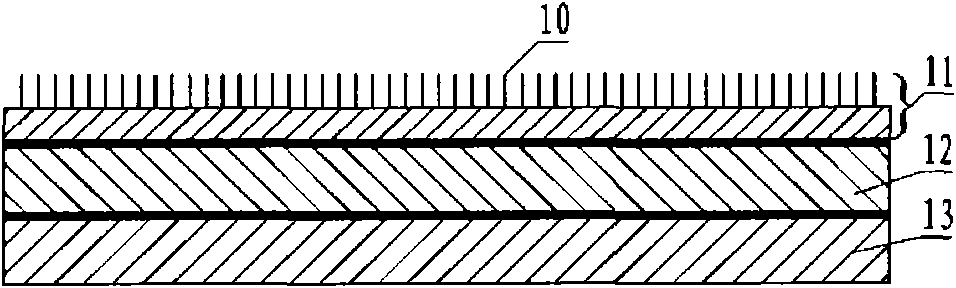

[0047] Such as figure 2 Shown, a kind of flexible nano-brush polishing pad, surface has no groove and hole, is made up of flexible nano-brush layer 11, substrate layer 12 and elastic substrate layer 13, and the flexible fiber of flexible nano-brush layer 11 working surface has following characteristics:

[0048] Diameter: ≈200nm;

[0049] Spacing (referring to the center distance of the axis of the fiber root): ≈270nm;

[0050] Length: ≈20μm;

[0051] Aspect ratio: ≈100:1.

[0052] The angle between the flexible fiber axis and the working surface in the flexible nano-brush layer tends to be 90°.

[0053] Its preparation method comprises the following steps:

[0054] (1) Anodic oxidation is used to produce an alumina template with an average pore diameter of 200nm, a depth of 60μm, and a hole center distance of ≈270nm; the angle between the axis of the hole and the surface of the template is 90°, that is, the axis of the hole is perpendicular to the surface of the template...

Embodiment 2

[0063] A kind of flexible nano-brush polishing pad, is made up of flexible nano-brush layer 11, matrix layer 12 and elastic substrate layer 13, groove is arranged on the surface of nano-brush polishing pad, flexible nano-brush layer 11 working surface has the flexible fiber of following characteristics:

[0064] Diameter: ≈80nm;

[0065] Spacing (referring to the center distance of the axis of the fiber root): ≈120nm;

[0066] Length: ≈160nm;

[0067] Length-to-diameter ratio: ≈2:1.

[0068] The angle between the flexible fiber axis and the working surface in the flexible nano-brush layer tends to be 90°.

[0069] The method for making the above-mentioned flexible nano brush polishing pad with grooves may further comprise the steps:

[0070] (1) Anodic oxidation is used to produce an alumina template with an average pore diameter of 80nm, a depth of 10μm, and a hole center distance of ~120nm. The size of the template is 10mm×10mm, and the angle between the axis of the hole ...

Embodiment 3

[0077] A flexible nano-brush polishing pad, without grooves and holes on the surface, is composed of a flexible nano-brush layer 11 and a base layer 12, and the flexible nano-brush layer 11 has a flexible fiber with the following characteristics on the working surface:

[0078] Diameter: 10μm;

[0079] Pitch: 10μm;

[0080] Length: 20μm;

[0081] Length-to-diameter ratio: 2:1.

[0082] The angle between the axis of the flexible fibers in the flexible nano-brush layer and the working surface is 60°.

[0083] Its preparation method comprises the following steps:

[0084] (1) Process a porous silicon template with an average pore diameter of 10 μm, a spacing of 10 μm, and a depth of 20 μm on the surface of the silicon wafer by plasma dry etching method DRIE; the angle between the axial direction of the hole and the surface of the template is 60°;

[0085] (2) Prepare a treated clean and smooth polyurethane plate (Shore hardness: 65D) as the base layer 12;

[0086] (3) dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com