Halogen-free phosphorus-free modified magnesium hydroxide flame retardant ethylene-vinyl acetate copolymer and preparation method thereof

A technology of vinyl acetate and magnesium hydroxide, applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, fibrous fillers, etc., can solve the problem of low tensile strength and limiting oxygen index, and vertical combustion performance has not been reported , low elongation at break, etc., to achieve remarkable flame retardant effects, good application prospects, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

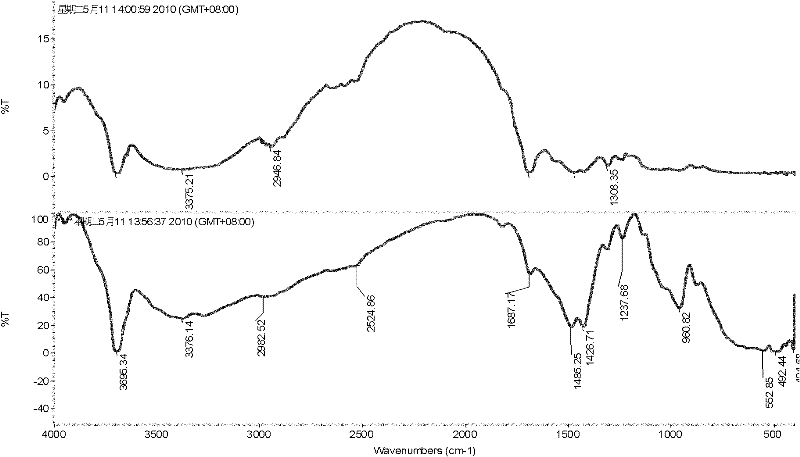

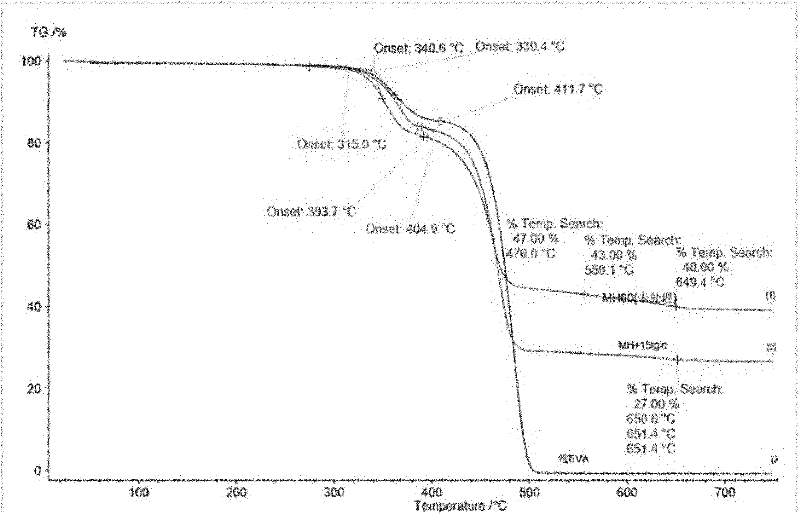

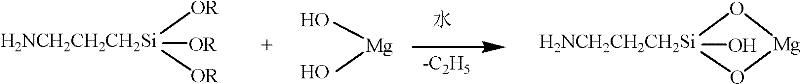

Method used

Image

Examples

Embodiment 1

[0029] 100 grams of magnesium hydroxide powder, 15 grams of γ-aminopropyltriethoxysilane coupling agent and 300 grams of water are mixed, and the emulsion is obtained after cutting at 8000 r / min for 20 minutes at room temperature. Add tris(glycidyl) isocyanurate dissolved in absolute ethanol, of which the mass of tris(glycidyl) isocyanurate is 15 grams, and the mass of absolute ethanol is 100 grams, continue at room temperature Shear at 8000r / min for 10min, then transfer the mixed solution to a three-necked flask, heat and stir to react at a temperature of 80℃, stirring for 2.5 hours, cooling to room temperature, filtering, washing with water, drying, twisting and sieving (250 Mesh screen) to obtain halogen-free and phosphorus-free modified magnesium hydroxide powder with a yield of 99%;

[0030] Take 42 grams of halogen-free and phosphorus-free modified magnesium hydroxide powder, 7 grams of compatibilizer and 21 grams of ethylene-vinyl acetate copolymer pellets, and mix them in...

Embodiment 2

[0035] 100 grams of magnesium hydroxide powder, 5 grams of γ-aminopropyltrimethoxysilane coupling agent and 200 grams of water are mixed, and the emulsion is obtained after cutting at 5000 r / min for 10 minutes at room temperature. Add tris(glycidyl) isocyanurate dissolved in absolute ethanol, of which the mass of tris(glycidyl) isocyanurate is 5 grams, and the mass of absolute ethanol is 35 grams. Continue to room temperature Cut at 5000r / min for 10min, then transfer the mixed solution into a three-necked flask, heat and stir to react, the temperature is 60℃, the stirring time is 2 hours, cool to room temperature, filter, wash with water, dry, twist and crush, sieving (250 Mesh screen) to obtain halogen-free and phosphorus-free modified magnesium hydroxide powder with a yield of 99%;

[0036] Take 42 grams of halogen-free and phosphorus-free modified magnesium hydroxide powder, 7 grams of compatibilizer and 21 grams of ethylene-vinyl acetate copolymer) pellets, and mix them in an...

Embodiment 3

[0039] 100 grams of magnesium hydroxide powder, 10 grams of γ-aminopropyltriethoxysilane coupling agent and 350 grams of water are mixed, and the emulsion is obtained after cutting at 10000 r / min for 20 minutes at room temperature. Add tris(glycidyl) isocyanurate dissolved in absolute ethanol, of which the mass of tris(glycidyl) isocyanurate is 5 grams and the mass of absolute ethanol is 50 grams, continue to room temperature Shear at 10000r / min for 10min, then transfer the mixed solution to a three-necked flask, heat and stir to react at a temperature of 80℃, stirring for 3 hours, cool to room temperature, filter, wash with water, dry, twist and crush, sieving (250 Mesh screen) to obtain halogen-free and phosphorus-free modified magnesium hydroxide powder with a yield of 98%;

[0040] Take 42 grams of halogen-free and phosphorus-free modified magnesium hydroxide powder, 7 grams of compatibilizer and 21 grams of ethylene-vinyl acetate copolymer pellets, and mix them in an interna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com