Method for preparing high-flow high-heat-resistance transparent polyvinyl chloride alloy capable of injection molding

A polyvinyl chloride and injection molding technology, which is applied in the field of preparation of transparent polyvinyl chloride alloys, can solve the problems of insufficient heat resistance and toughness of polyvinyl chloride, difficulty in taking into account the fluidity of polyvinyl chloride, and restricting the application of rigid polyvinyl chloride. , to achieve the effect of improving compatibility, improving fluidity and promoting uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

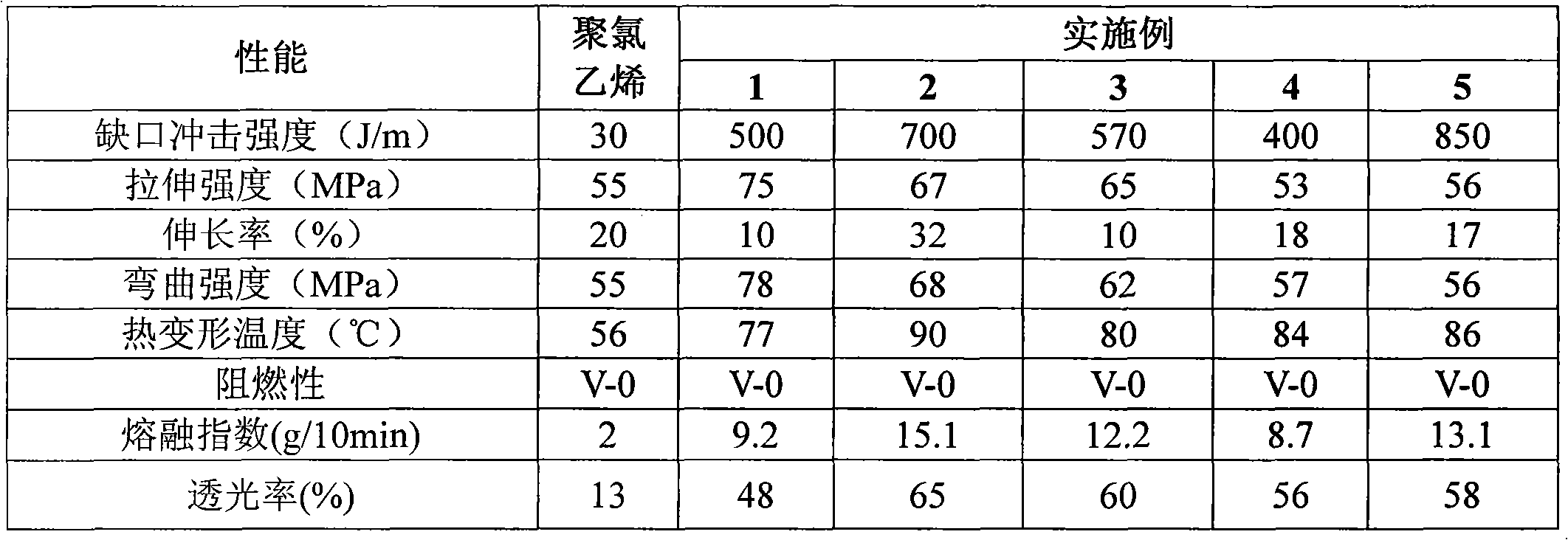

Embodiment 1

[0019] Add 100 parts by weight of S700 polyvinyl chloride and 1 part by weight of organotin stabilizer into a high-speed mixer, mix to 50°C, add 1 part by weight of acrylic processing aid, 1 part by weight of monoglycerin stearate ester, mixed to 70°C, added 0.3 parts by weight of oxidized polyethylene wax, mixed to 90°C, added 4 parts by weight of polyurethane elastomer, 4 parts by weight of polymethyl methacrylate and 1 part by weight of methyl methacrylate-butanedi ethylene-styrene copolymer, mixed to 110°C and cooled to obtain a polyvinyl chloride compound; the polyvinyl chloride compound was added to a conical twin-screw extruder, and the temperature in the first zone was 130°C, and the temperature in the second zone was 140 ℃, the temperature in the third zone is 150 ℃, the temperature in the fourth zone is 140 ℃, the screw speed is 4 rpm, and the feeding speed is 5 rpm. transparent polyvinyl chloride alloy.

Embodiment 2

[0021] Add 100 parts by weight of grade S1000 polyvinyl chloride and 3 parts by weight of organotin stabilizer into a high-speed mixer, mix to 60°C, add 3 parts by weight of acrylic processing aids, 3 parts by weight of monoglyceryl stearate , mixed to 80 ° C, added 1 weight part of oxidized polyethylene wax, mixed to 100 ° C, added 100 parts by weight of polyurethane elastomer, 100 parts by weight of methyl methacrylate-methyl acrylate copolymer and 50 parts by weight of methyl methacrylate Ester-butadiene-styrene copolymer, mixed to 120°C and cooled to obtain a polyvinyl chloride compound; the polyvinyl chloride compound was added to a conical twin-screw extruder, and the temperature in the first zone was 170°C, and the temperature in the second zone was The temperature in the zone is 180°C, the temperature in the third zone is 185°C, the temperature in the fourth zone is 180°C, the screw speed is 30 rpm, and the feeding speed is 20 rpm. Thermo-injection moldable clear polyv...

Embodiment 3

[0023] Add 100 parts by weight of SG3 polyvinyl chloride and 2 parts by weight of liquid calcium zinc stabilizer into a high-speed mixer, mix to 55°C, add 2 parts by weight of acrylic processing aids, 2 parts by weight of stearic acid, and mix to 75°C, add 1 part by weight of oxidized polyethylene wax, mix to 95°C, add 30 parts by weight of polyurethane elastomer, 50 parts by weight of polymethyl methacrylate and 25 parts by weight of methyl methacrylate-butadiene-benzene Ethylene copolymer, mixed to 120°C and cooled to obtain a polyvinyl chloride compound; the polyvinyl chloride compound was added to a conical twin-screw extruder, and the temperature in the first zone was 150°C, the temperature in the second zone was 160°C, and the temperature in the third zone was 160°C. The temperature in the zone is 165°C, the temperature in the fourth zone is 160°C, the screw speed is 15 rpm, and the feeding speed is 10 rpm, and it is melt-extruded and pelletized to obtain a high-fluidity,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com