Achromobacter xylosoxidans strain and application thereof

A colorless bacillus, xylose technology, applied in bacteria, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of increased BOD, unsatisfactory discharge, and few reports on microbial degradation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. Isolation, purification and identification of Achromobacter xylosoxidans N4 CGMCC No. 3632.

[0020] In May 2009, the activated sludge from the denim printing and dyeing wastewater treatment tank (collected from a denim printing and dyeing factory in Haining City, Zhejiang Province) was diluted with sterile water, and coated with solid medium (1L solid medium contains 3g of beef extract, Peptone 10g, NaCl 5g, agar 15g, and the rest are water) plate, 18 bacterial strains were isolated, and the bacterial strain was purified by streaking on the plate. The isolated and purified 18 strains were respectively inserted into liquid medium (1L medium contains 3g of beef extract, 10g of peptone, 5g of NaCl, and the rest is water) with an inoculation loop for liquid culture. The culture temperature was 28°C and 180rpm for 24- After 48h, join in indoloquinone or anthranilic acid aqueous solution with 5% (volume percentage content) inoculum, liquid chromatography measureme...

Embodiment 2

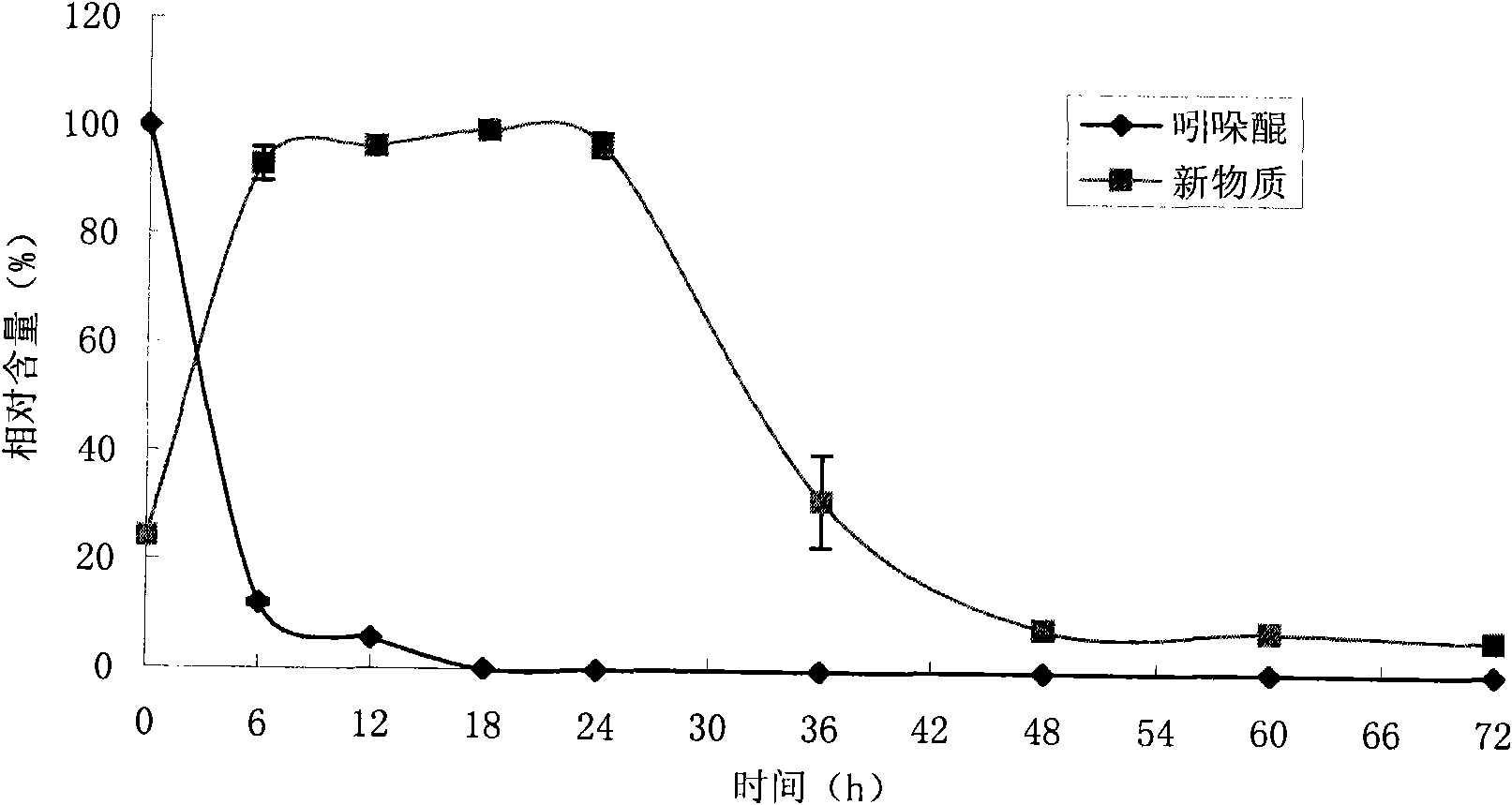

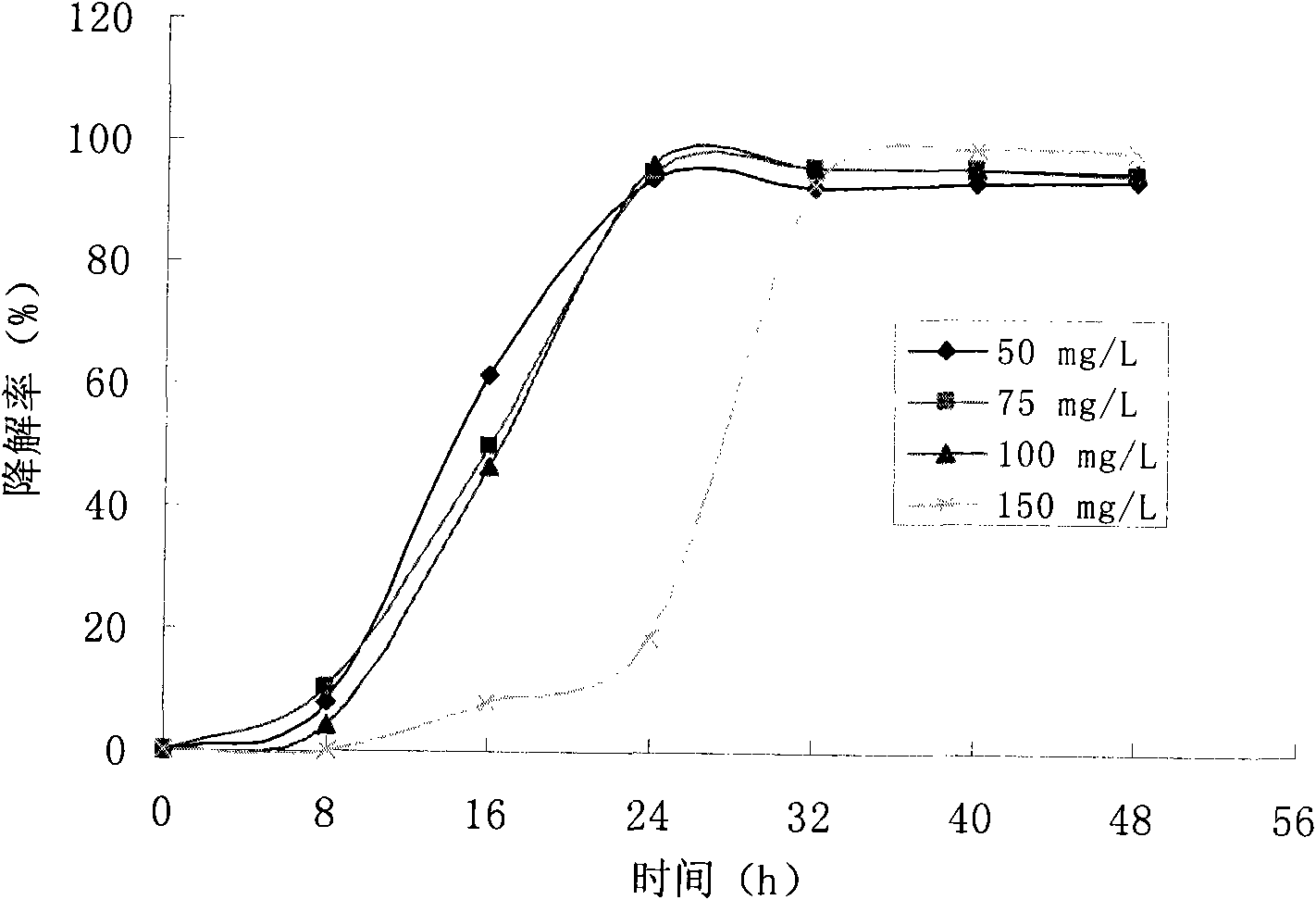

[0025] Example 2. Validation test of the effect of Achromobacter xylosoxidans N4 CGMCC №.3632 on the degradation of indoloquinone

[0026] 1. Verification test on the degradation effect of 100 mg / L indoloquinone

[0027] Medium for Achromobacter xylosoxidans N4 CGMCC №.3632:

[0028] Solid medium (1L): 3g of beef extract, 10g of peptone, 5g of NaCl, 15g of agar, and the rest is water.

[0029] Liquid medium (1L): 3g of beef extract, 10g of peptone, 5g of NaCl, and the rest is water.

[0030] Inoculate Achromobacter xylosoxidans (Achromobacter xylosoxidans) N4 CGMCC №.3632 into the liquid medium, and cultivate it at 28°C and 180 rpm for 24-48h until the OD of the culture medium is reached. 600 0.6, then in a non-sterile environment, the culture solution was inoculated into the aqueous solution of 100 mg / L indoloquinone according to the volume percentage of 5%, and the control group was added with 5% distilled water according to the volume percentage, at 28 ° C, Cultivate at ...

Embodiment 3

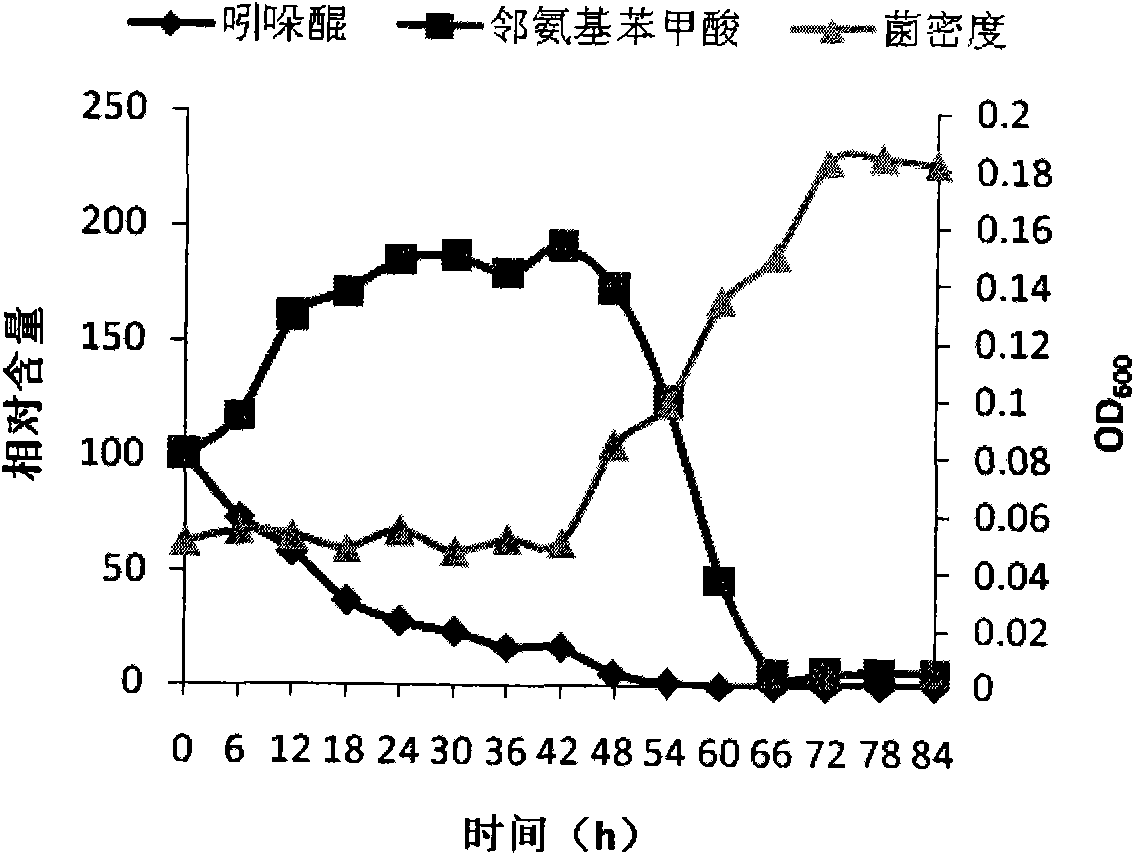

[0037] Example 3, Achromobacter xylosoxidans (Achromobacter xylosoxidans) N4 CGMCC №.3632 effect verification test on the degradation of the mixture of indoloquinone and anthranilic acid

[0038] Medium for Achromobacter xylosoxidans N4 CGMCC №.3632:

[0039] Solid medium (1L): 3g of beef extract, 10g of peptone, 5g of NaCl, 15g of agar, and the rest is water.

[0040] Liquid medium (1L): 3g of beef extract, 10g of peptone, 5g of NaCl, and the rest is water.

[0041] Inoculate Achromobacter xylosoxidans (Achromobacter xylosoxidans) N4 CGMCC №.3632 into the liquid medium, and cultivate it at 28°C and 180rpm for 24-48h until the OD of the culture medium is reached. 600 0.6, then in a non-sterile environment, the fermentation broth was inoculated into a mixed system containing 100mg / L indoloquinone and 100mg / L anthranilic acid in an amount of 5% by volume, and the control group was in the mixed system Adding distilled water with a volume percentage of 5%, cultivated at 28°C and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com