Fermentation method for production of recombination protein by lactose-induced pMFH carrier

A fermentation method and recombinant protein technology are applied in the field of genetic engineering drug preparation, and achieve the effects of simple post-processing, simple fermentation method and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

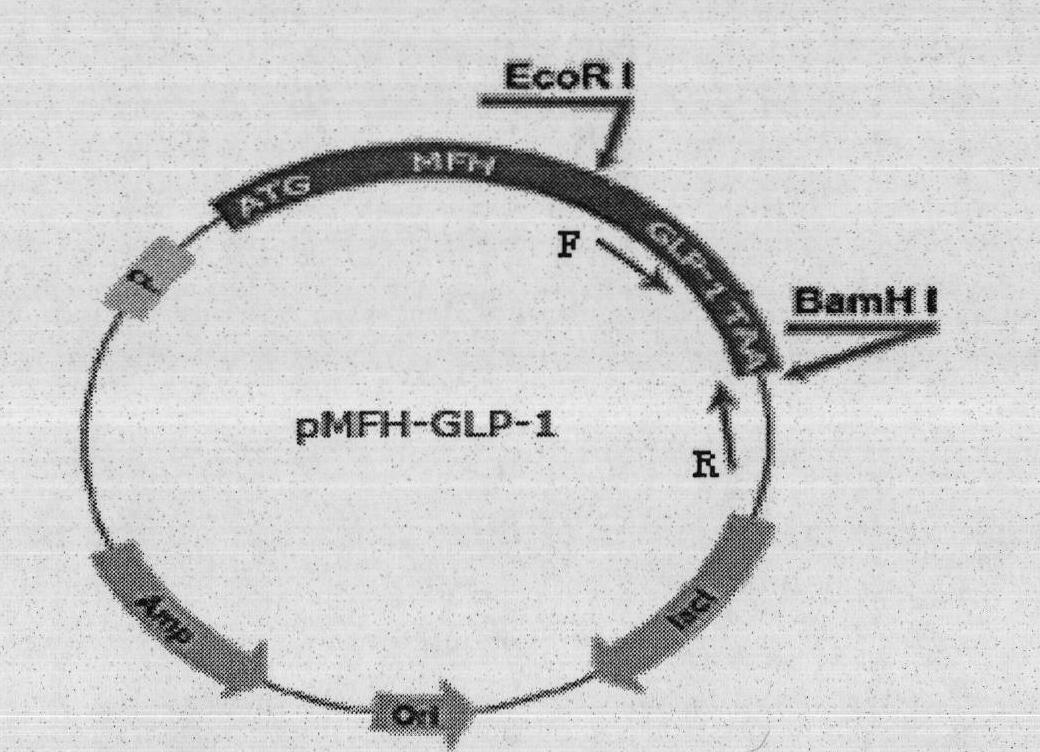

[0038] (1) Construction of pMFH-GLP-1-DP6.2 prokaryotic expression vector

[0039] ① Construction of pMFH-GLP-1(7-37) recombinant plasmid

[0040] GLP-1(7-37) cDNA sequence is:

[0041] CAC GCT GAA GGT ACC TTC ACT TCC GAC GTT TCC TCT TAC CTG GAA GGG CAG GCT GCA AAAGAA TTT ATC GCT TGG CTG GTT AAA GGT CGT GGC TAA

[0042] Design 4 oligonucleotide fragments according to the sequence of GLP-1 (7-37) above, the 5' end of primer 1 introduces the EcoR Ⅰ sticky end; the 5' end of primer 4 contains the BamH Ⅰ sticky end, and make it There are 27 bases complementary to primer 1 at the 3' end, and the primer sequence is as follows:

[0043] EcoR Ⅰ

[0044] Primer 1 (P1): 5' CAC GCT GAA GGT ACC TTC ACT TCC GAC GTT TCC TCT TAC CTGGAA GGG CAG GCT GCA AAA-3’

[0045] Primer 2 (P2): 5'-GAA TTT ATC GCT TGG CTG GTT AAA GGT CGT GGC TAA G-3'

[0046] Primer 3 (P3): 5'-GGA AAC GTC GGA AGT GAA GGT ACC TTC AGC GTG G-3'

[0047] BamH Ⅰ

[0048] Primer 4 (P4): 5' TTA GCC ACG ACC TTT AAC CAG...

Embodiment 2

[0117] (1) The preparation of the secondary seeds of this embodiment is the same as that of Embodiment 1.

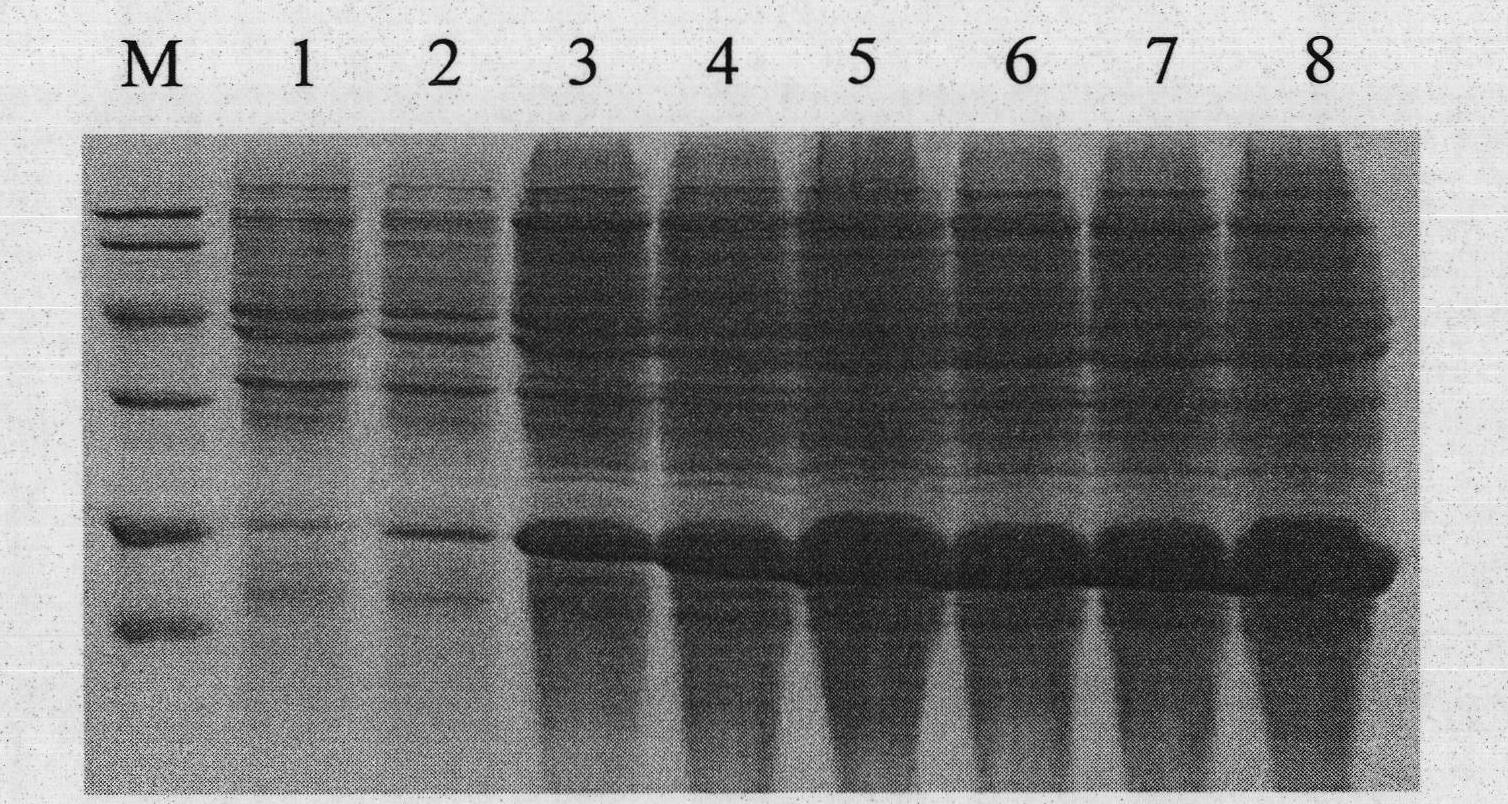

[0118] (2) Fermentation and induction: inoculate the secondary seeds in the fermentation medium, the fermenter culture conditions: 5L fermenter (Taiwan Bio-top company, model: BTF-A5L) working volume is 3.5L, inoculum size is 12% (volume percentage), the fermentation temperature is 37°C, the dissolved oxygen is controlled at 30% by adjusting the ventilation and stirring speed (0-1000rpm), and the pH value is controlled at 7.25. During the fermentation process, 2mol / L HCl and 2mol / L NaOH are added To adjust the pH value, the fermentation time is 13h; 4h after inoculation, start to add 200ml of lactose feed solution at a slow speed (1h after feeding), at this time, the pH value of the fermentation liquid will always drop, because glucose metabolism will produce acid , when the added glucose is consumed, the pH value will start to rise, and at this time it enters the first ...

Embodiment 3

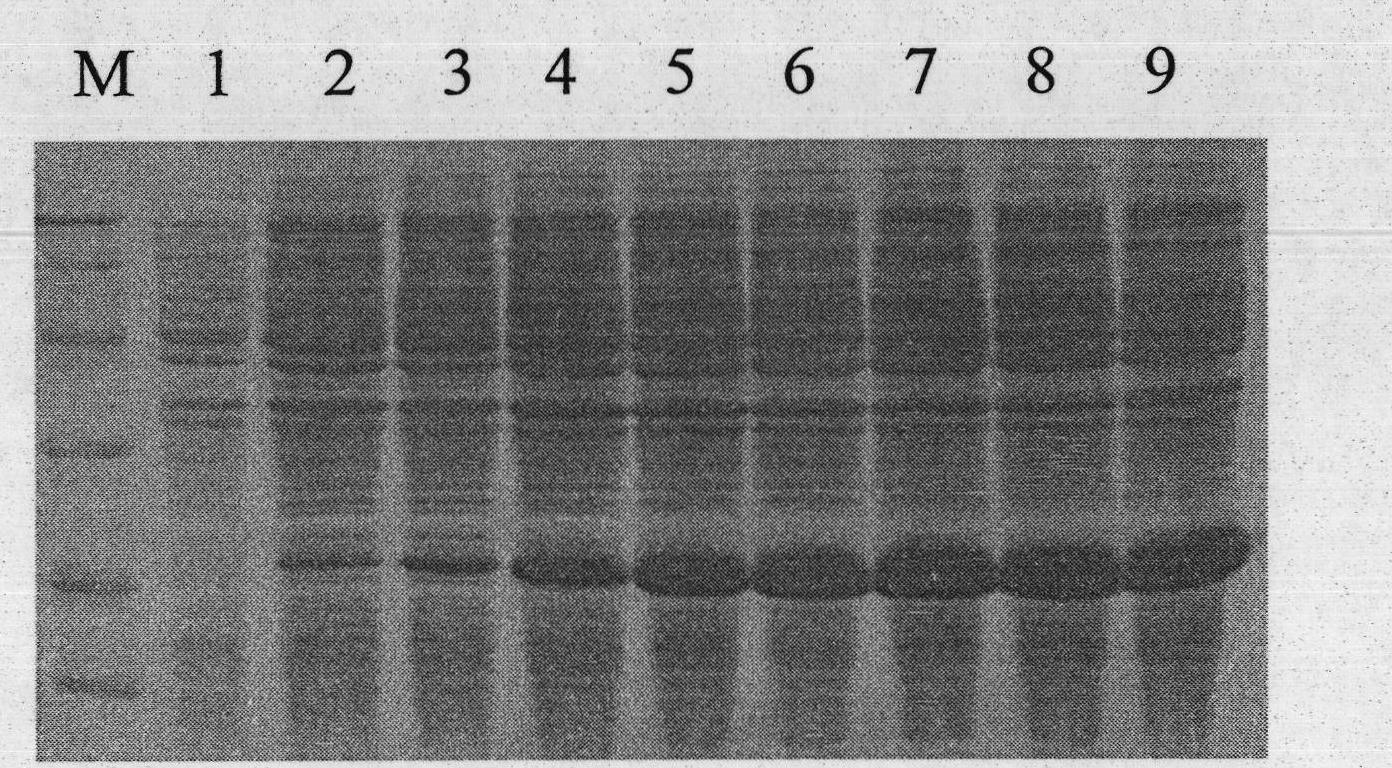

[0122] (1) Activation of bacterial classification: Glycerol bacterium pMFH-GLP-1-DP6.2-BL21 (DE3) is carried out shaking flask culture, fills 15ml culture medium in 150ml Erlenmeyer flask, activates, obtains the activated bacterial classification; Shake The condition of bottle culture is 35 ℃, 250rpm cultivates 20h, and the inoculum size of glycerol bacteria is 0.5% (volume percentage), and culture medium is the LB culture medium that contains ampicillin, and the concentration of ampicillin is 100 μ g / ml; The group of LB culture medium The components are as follows: tryptone 10g / L, yeast powder 5g / L, NaCl 10g / L, prepared with deionized water, pH 6.8;

[0123] (2) Preparation of first-class seeds: inoculate the activated bacterial classification prepared in step (1) into the fermentation basal medium and carry out shake flask culture; the condition of shake flask culture is: the filling volume is 25ml fermentation base in 250ml shake flask Culture medium, cultivate overnight at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com