Preparation method of zinc oxide nanosphere

A technology of zinc oxide nanometer and zinc salt, which is used in nanostructure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.219g of zinc acetate into a 60mL tall beaker, add 10mL of deionized water, stir to dissolve; then measure 1.98mL of triethanolamine into a conical flask, add 50mL of deionized water, stir to dissolve; then add the zinc acetate aqueous solution In the Erlenmeyer flask, continue to stir, a small amount of white flocculent precipitates are formed when mixing; then put the Erlenmeyer flask containing the reaction mixture into a microwave generator for microwave irradiation, set the microwave power to 300W, and the reaction temperature to 60 ℃, microwave time 10min; naturally cool to room temperature after the reaction, a large amount of white precipitate is formed, filter the precipitate, wash with water 3 times; heat the precipitate in an oven for 8 hours at 60°C, collect the white product to obtain the present invention of zinc oxide nanospheres.

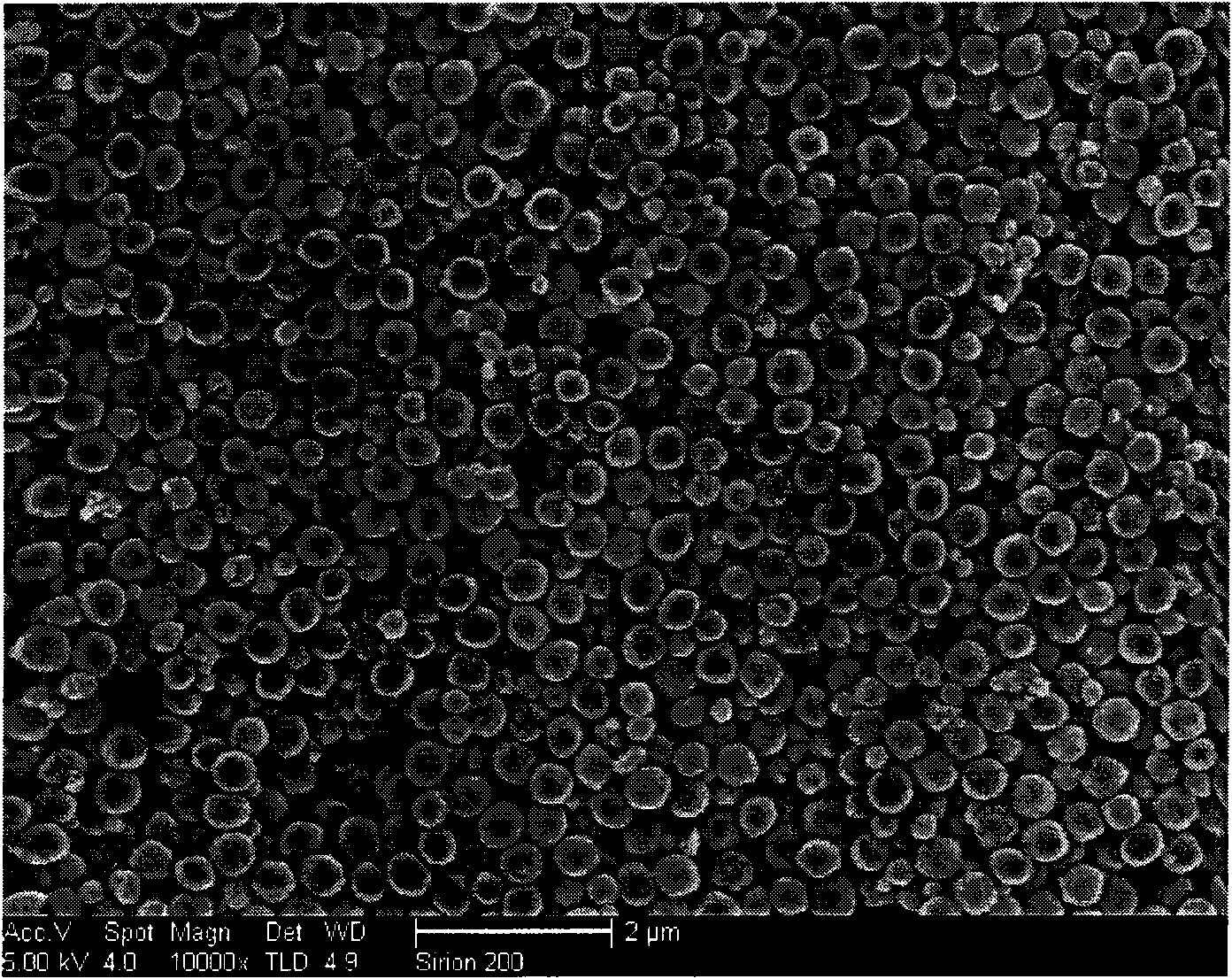

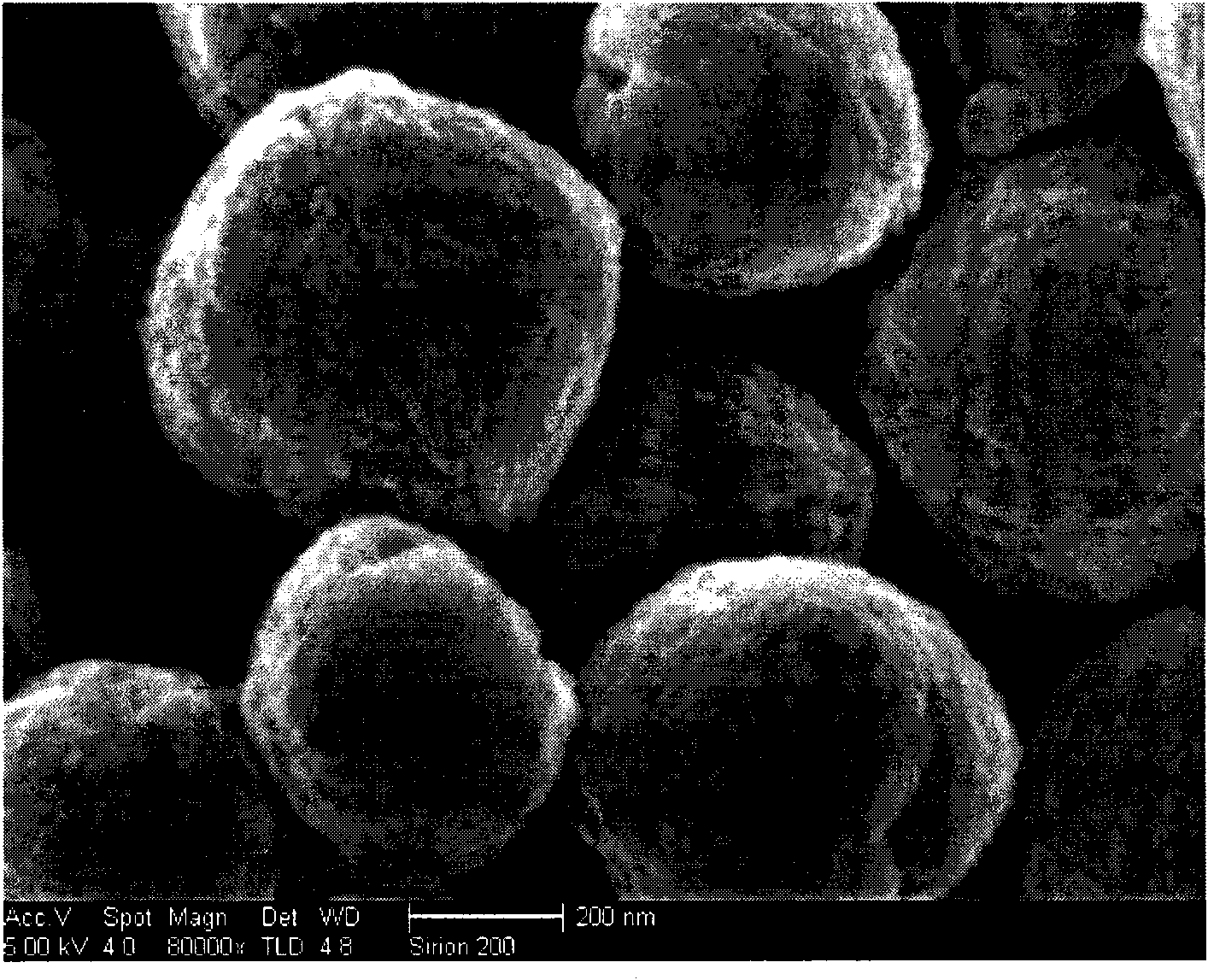

[0026] See attached figure 1 , the low magnification field scanning electron micrograph of the zinc oxide nanosphere...

Embodiment 2

[0031]Weigh 0.220g of zinc acetate into a 60mL tall beaker, add 10mL of deionized water, stir to dissolve; then measure 1.32mL of triethanolamine into a conical flask, add 50mL of deionized water, stir to dissolve; then add the zinc acetate aqueous solution In the Erlenmeyer flask, continue to stir, a small amount of white flocculent precipitates are formed when mixing; then put the Erlenmeyer flask containing the reaction mixture into a microwave generator for microwave irradiation, set the microwave power to 300W, and the reaction temperature to 60 ℃, microwave time 10min; naturally cool to room temperature after the reaction, a large amount of white precipitate is formed, filter the precipitate, wash with water 3 times; heat the precipitate in an oven for 8 hours at 60°C, collect the white product to obtain the present invention of zinc oxide nanospheres.

Embodiment 3

[0033] Weigh 0.291g of zinc nitrate in a 60mL tall beaker, add 10mL of deionized water, stir to dissolve; then measure 1.32mL of triethanolamine into the Erlenmeyer flask, add 50mL of deionized water, stir to dissolve; then add zinc acetate aqueous solution In the Erlenmeyer flask, continue to stir, a small amount of white flocculent precipitates are formed when mixing; then put the Erlenmeyer flask containing the reaction mixture into a microwave generator for microwave irradiation, set the microwave power to 300W, and the reaction temperature to 60 ℃, microwave time 10min; naturally cool to room temperature after the reaction, a large amount of white precipitate is formed, filter the precipitate, wash with water 3 times; heat the precipitate in an oven for 8 hours at 60°C, collect the white product to obtain the present invention of zinc oxide nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com