Method for treating liquid waste of silicon steel passivation solution

A treatment method and technology of passivation solution, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. COD and chromium concentration can not meet the standard discharge and other problems, to achieve the effect of recycling waste liquid, stable treatment and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

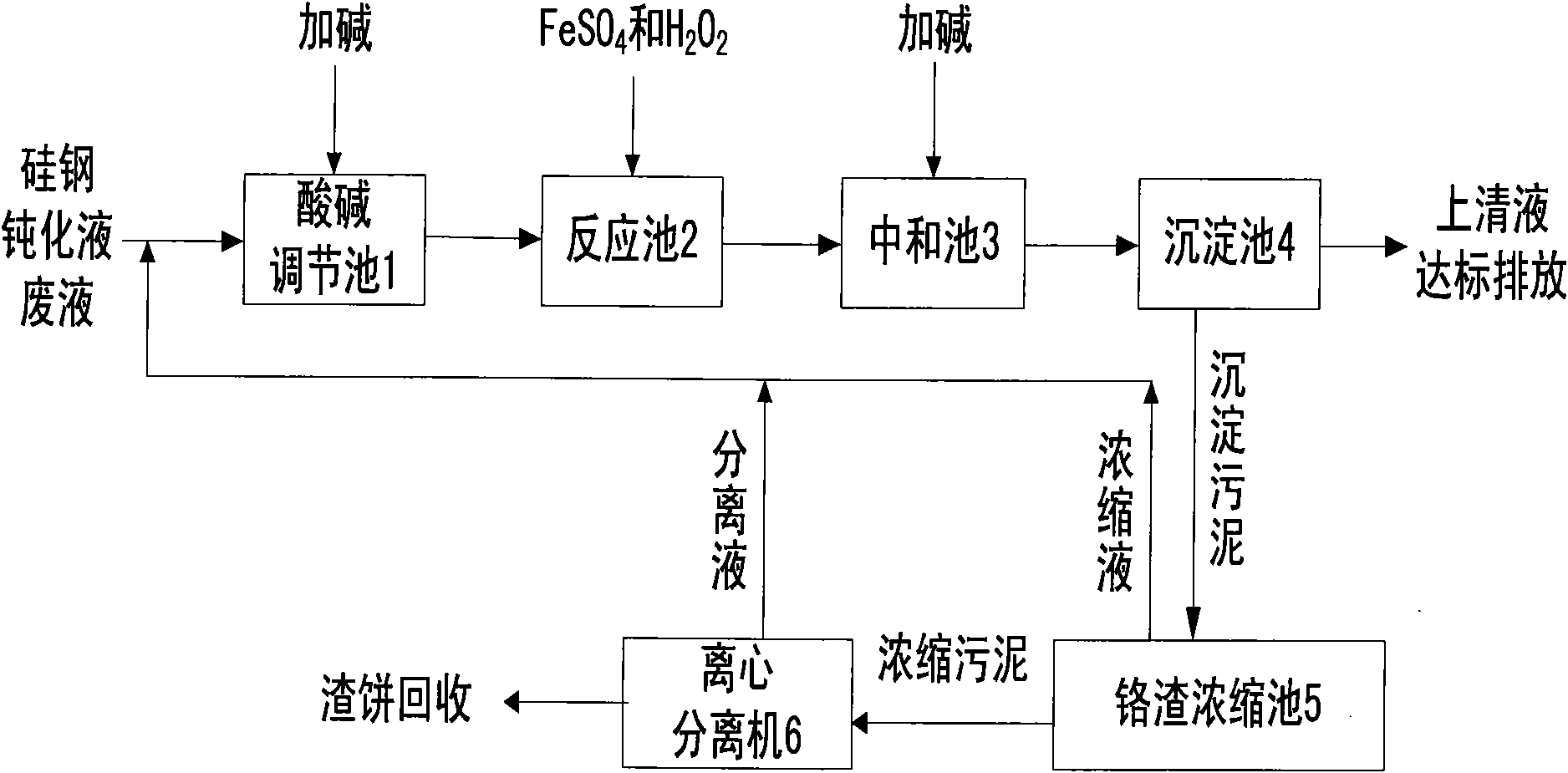

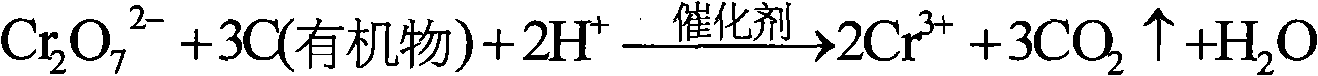

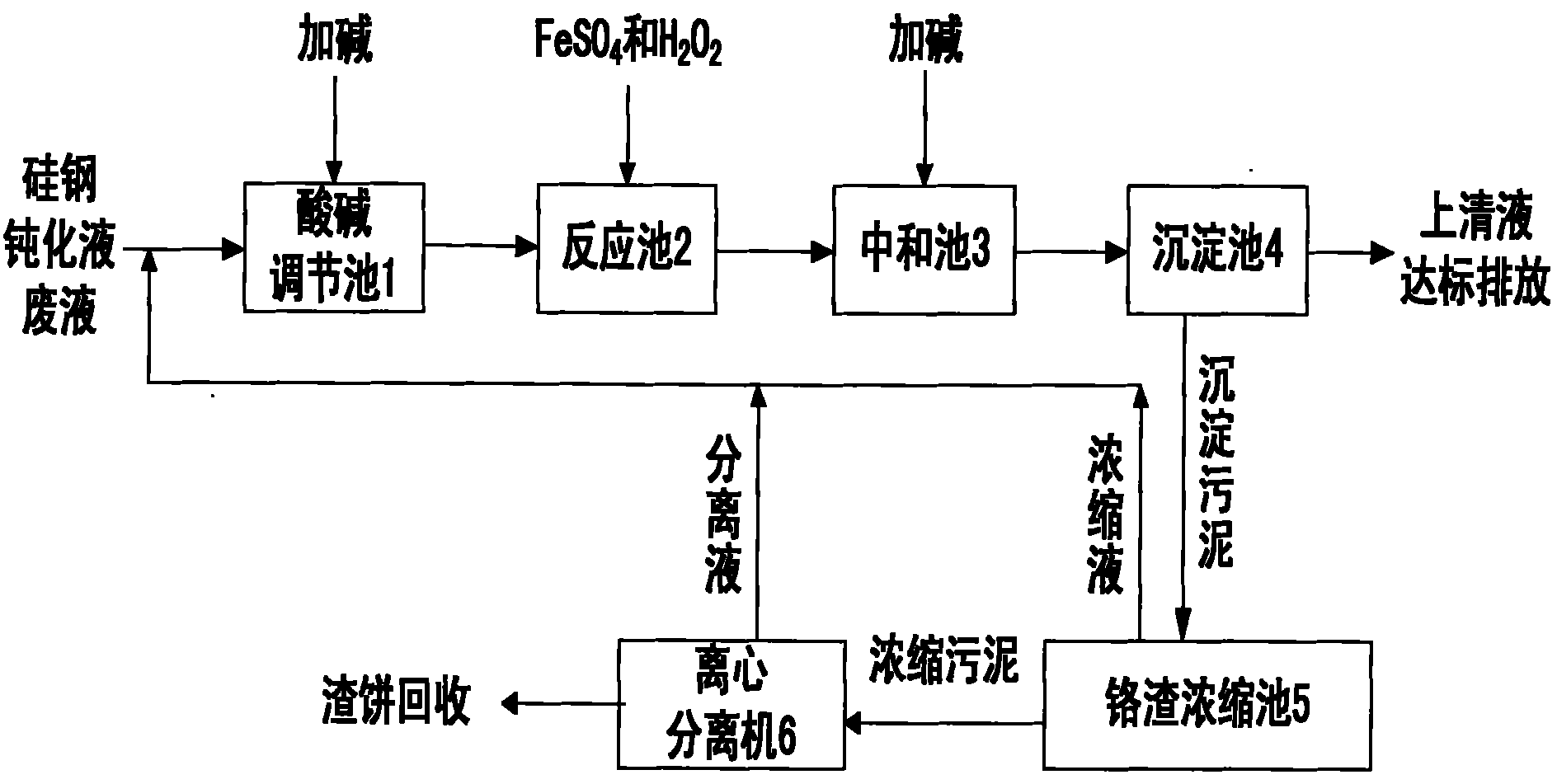

Embodiment 1

[0025] What this embodiment deals with is 8m 3 Silicon steel passivation liquid waste 1: original waste liquid pH=0.5-2, Cr 6+ The concentration is 2958.89mg / L, and the COD concentration is 1351.3mg / L. The steps of the specific embodiment are as follows: first, the silicon steel passivation liquid waste liquid is collected through the acid-base adjustment sedimentation tank 1, and the alkali is added to adjust the pH to 3, mixed and homogenized, and then injected into the reaction tank 2 by the sewage pump, and FeSO is added at the same time 4 ·7H 2 O658.08kg and 30% H 2 o2 536.54kg, the waste liquid flows into the neutralization tank 3 by itself after reacting in the reaction tank 2 for 60 minutes, adds alkali to adjust the pH to 7, stays for 5 minutes, then flows into the sedimentation tank 4 by gravity, and after 30 minutes of precipitation, the supernatant is discharged up to the standard, and the sedimentation sludge is passed through After the chromium slag concentra...

Embodiment 2

[0027] What this embodiment deals with is 20m 3 Silicon steel passivation liquid waste 2: original waste liquid pH=2-3, Cr 6+ The concentration is 295.65mg / L, and the COD concentration is 135.13mg / L. The steps of the specific embodiment are as follows: first, the silicon steel passivation liquid waste liquid is collected through the acid-base adjustment sedimentation tank 1, and the alkali is added to adjust the pH to 4, mixed and homogenized, and then injected into the reaction tank 2 by the sewage pump, and FeSO is added at the same time 4 ·7H 2 O164.40kg and 30% H 2 o 2 134.03kg, the waste liquid flows into the neutralization tank 3 by itself after reacting in the reaction tank 2 for 60 minutes, adds alkali to adjust the pH to 8, stays for 7 minutes, then flows into the sedimentation tank 4 by gravity, and after 40 minutes of precipitation, the supernatant is discharged up to the standard, and the sedimentation sludge is passed through After the chromium slag concentra...

Embodiment 3

[0029] What this embodiment deals with is 10m 3 Silicon steel passivation liquid waste 3: original waste liquid pH=1-2, Cr 6+ The concentration is 428.94mg / L, and the COD concentration is 529.74mg / L. The steps of the specific embodiment are as follows: first, the silicon steel passivation liquid waste liquid is collected through the acid-base adjustment sedimentation tank 1, and the alkali is added to adjust the pH to 3, mixed and homogenized, and then injected into the reaction tank 2 by the sewage pump, and FeSO is added at the same time 4 ·7H 2 O119.25kg and 30% H 2 o 2 97.23kg, the waste liquid flows into the neutralization tank 3 by itself after reacting in the reaction tank for 60 minutes, adds alkali to adjust the pH to 7, stays for 6 minutes, then flows into the sedimentation tank 4 by gravity, and after 35 minutes of precipitation, the supernatant is discharged up to the standard, and the precipitated sludge is passed through chromium After being concentrated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com